Low-nitrogen type efficient incandescent light

An ever-burning, high-efficiency technology, applied in the field of ever-burning lights, can solve the problems of excessive NOx and CO, incomplete combustion of CO, and low temperature of the heating furnace, achieving the effects of complete combustion, enhanced disturbance, and improved burnout rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] specific implementation plan

[0018] The present invention will be further described below in conjunction with the embodiment in the accompanying drawings:

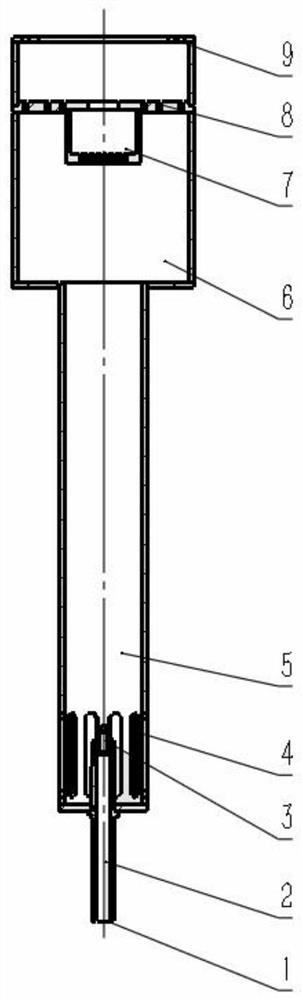

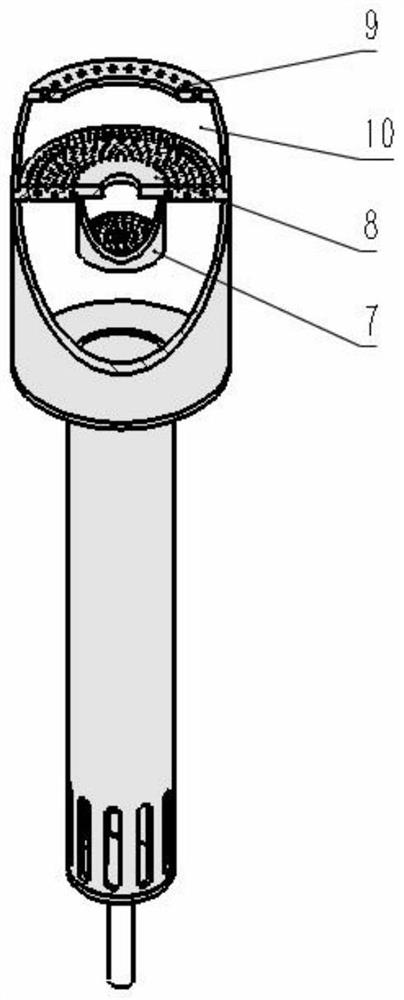

[0019] The low-nitrogen high-efficiency permanent lamp of the present invention is mainly composed of a gas pipe 2, a gas nozzle 3, a gas mixture pipe 5, an expansion booster chamber 6, a limited-space internal combustion chamber 10, and a fire collecting plate; the gas nozzle 3 is arranged at the end of the gas pipe 2 , with the gas pipe 2 extending into the gas mixture pipe 5, the gas nozzle 3 and the gas mixture pipe 5 are coaxially arranged, and the lower part of the gas mixture pipe 5 is located on the circumferential wall around the gas nozzle 3, and a plurality of strip-shaped self-priming pipes are evenly arranged. Type air inlet 4, the upper part of the mixed gas pipe 5 is connected with an expansion booster chamber 6, the equivalent diameter ratio of the expansion booster chamber 6 and the mixed gas tube...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com