Novel synchronizer with rolling type sliding block

A rolling and synchronizer technology, which is applied in the direction of mechanically driven clutches, clutches, couplings, etc., can solve problems such as poor friction performance, insufficient driving effect, failure of neutral gear positioning, etc., to improve the effect, improve the overall operation effect, reduce The effect of fixed gear stuck

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

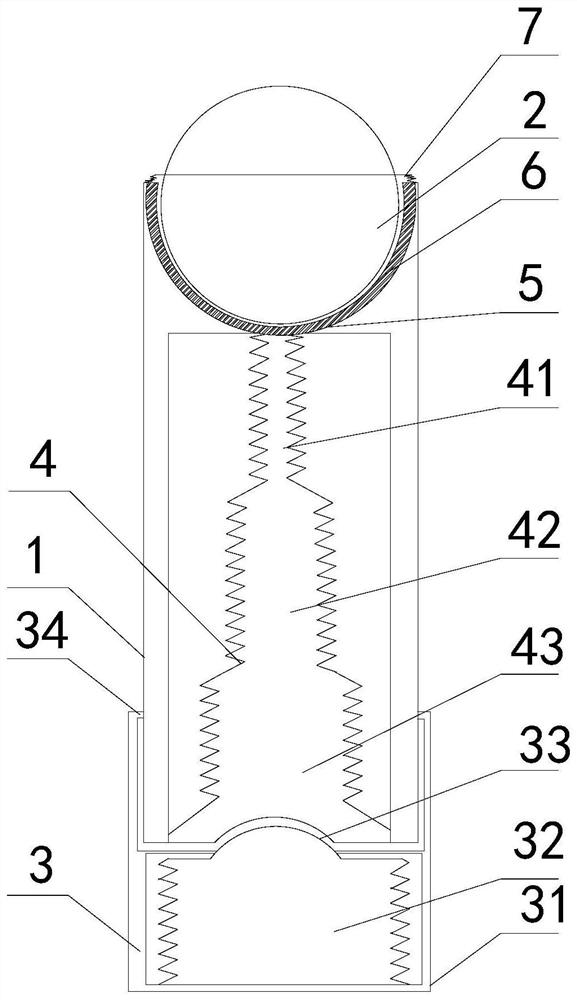

[0018] Embodiment 1: A new type of synchronizer with a rolling slider, including a tooth sleeve, a gear hub and a synchronous lock ring, the gear sleeve and the gear hub are fixed by the synchronous lock ring, and the gear hub is provided with a rolling positioning The slider, the rolling positioning slider includes a slider body 1, a ball 2 and an air spring seat 3, the slider body 1 is provided with a three-stage air spring chamber 4, and the air spring seat 3 is fixed on the three-stage The bottom of the first-stage air spring chamber 4, the top of the third-stage air spring chamber 4 is fixed with a hemispherical bushing 5; the hemispherical bushing 5 is provided with a sponge layer 6, and lubricating oil is stored in the sponge layer 6, and the sponge layer 6 is provided with The ball 2, the top of the slider body 1 is located on both sides of the bushing 5 and is provided with an elastic limit assembly 7 to limit the sliding of the ball 2;

[0019] The three-stage air sp...

Embodiment 2

[0024] Embodiment 2: The specific structure and implementation of this embodiment are the same as those in Embodiment 1, the difference being that the composition of the new copper alloy material is: copper: 52%; aluminum: 33.91%; manganese: 0.5% ; Iron: 6%; Silicon: 6%; Chromium: 0.5%; Carbon: 1%; Yttrium: 0.05%; Nickel: 0.02%; Magnesium: 0.02%; The coefficient of friction of this material can reach 0.14.

Embodiment 3

[0025] Embodiment 3: The specific structure and implementation method of this embodiment are the same as those in Embodiment 1, the difference being that the composition of the new copper alloy material is: copper: 53%; aluminum: 35.81%; manganese: 0.5% ; Iron: 5%; Silicon: 5%; Chromium: 0.5%; Carbon: 0.1%; Yttrium: 0.05%; Nickel: 0.02%; Magnesium: 0.02%;

[0026] The synchronizer prepared by the invention has the advantages of light weight, high strength and excellent friction transmission performance, and has broad application prospects.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com