Sliding vane type pressure matcher

A matcher, slide vane technology, applied in the field of slide vane pressure matcher

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

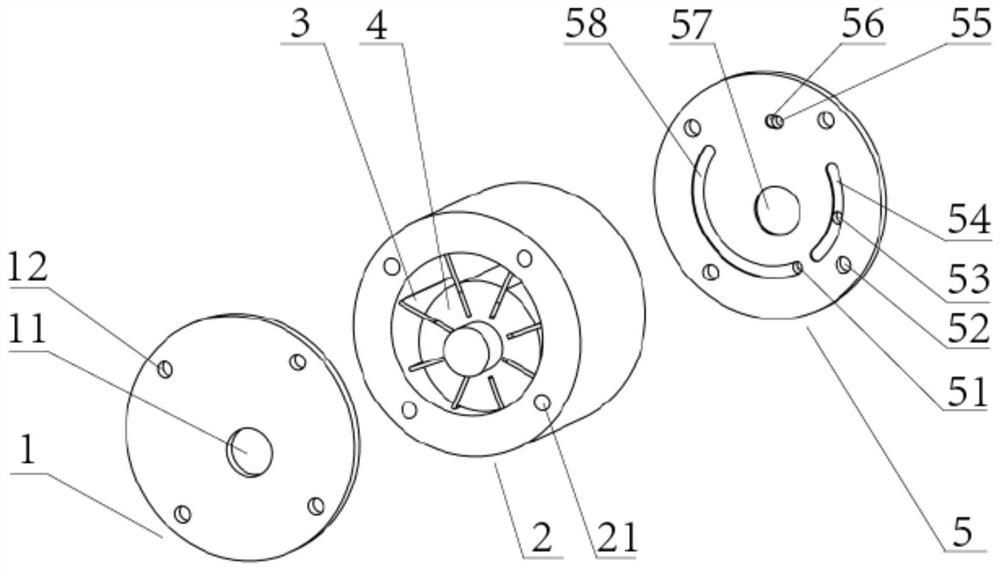

[0049] Such as Figure 1-Figure 8 As shown, the present embodiment provides a sliding vane 3 type pressure adapter, including: a hollow cylinder 2 and a rotating part.

[0050] The cylinder 2 is provided with a low-pressure suction hole 53 , a high-pressure suction hole 55 and an exhaust hole 51 communicating with the inside of the cylinder 2 . The rotating part is used to generate suction, and the rotating part is installed in the cylinder 2, and a plurality of variable-sized suction chambers are formed by the rotating part and the inner wall of the cylinder 2, and the rotation of the variable-sized suction chambers is sequentially connected with the low-pressure suction chamber. Air hole 53, high-pressure suction hole 55 and exhaust hole 51 are communicated, and the volume of a plurality of described variable-size suction chambers communicates with described low-pressure suction hole 53 to communicates with described high-pressure suction hole 55 process Gradually increasin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com