A kind of polyurethane resin composition and its preparation method and application

A technology of polyurethane resin and composition, which is applied in the field of polyurethane, can solve the problems such as the inability to realize the injection molding of TPR soles, and achieve the effects of easy sliding and bending, good low-temperature flexibility, and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

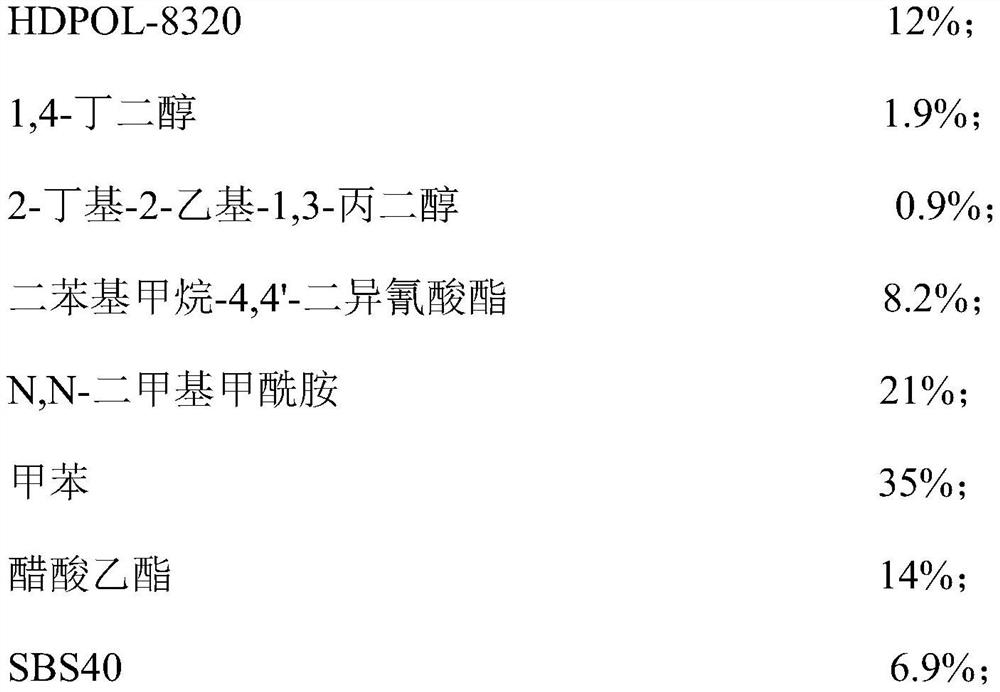

[0056] In this embodiment, a polyurethane resin composition is provided, and the polyurethane resin composition includes a first composition and a second composition, and the first composition includes the following components by weight percentage:

[0057]

[0058] The second composition includes the following components by weight:

[0059]

[0060] The preparation method includes the following steps:

[0061] (1) Preparation of the first composition: HDPOL-8320, 1,4-butanediol, 2-butyl-2-ethyl-1,3-propanediol, N,N-dimethylformamide and part of toluene Mix evenly, cool down to 58°C, add part of diphenylmethane-4,4'-diisocyanate to start the reaction, the solid content of the reaction is 40%, the molar ratio of isocyanate groups and hydroxyl groups in the reaction solution is 0.95, and the temperature is raised to 70°C , react until the hydrogen peroxide test does not turn yellow; add part of diphenylmethane-4,4'-diisocyanate, so that the molar ratio of isocyanate group...

Embodiment 2

[0064] In this embodiment, a polyurethane resin composition is provided, and the polyurethane resin composition includes a first composition and a second composition, and the first composition includes the following components by weight percentage:

[0065]

[0066]

[0067] The second composition includes the following components by weight:

[0068]

[0069] The preparation method includes the following steps:

[0070] (1) Preparation of the first composition: HDPOL-8320, 1,4-butanediol, 2-butyl-2-ethyl-1,3-propanediol, N,N-dimethylformamide and part of toluene Mix evenly, cool down to 60°C, add part of diphenylmethane-4,4'-diisocyanate to start the reaction, the solid content of the reaction is 40%, the molar ratio of isocyanate groups and hydroxyl groups in the reaction solution is 0.95, and the temperature is raised to 75°C , react until the hydrogen peroxide test does not turn yellow; add part of diphenylmethane-4,4'-diisocyanate, so that the molar ratio of isoc...

Embodiment 3

[0073] In this embodiment, a polyurethane resin composition is provided, and the polyurethane resin composition includes a first composition and a second composition, and the first composition includes the following components by weight percentage:

[0074]

[0075] The second composition includes the following components by weight:

[0076]

[0077]

[0078] The preparation method includes the following steps:

[0079] (1) Preparation of the first composition: HDPOL-8330, 1,4-butanediol, 2-butyl-2-ethyl-1,3-propanediol, N,N-dimethylformamide and part of toluene Mix evenly, cool down to 55°C, add part of diphenylmethane-4,4'-diisocyanate to start the reaction, the solid content of the reaction is 40%, the molar ratio of isocyanate groups and hydroxyl groups in the reaction solution is 0.95, and the temperature is raised to 73°C , react until the hydrogen peroxide test does not turn yellow; add a part of diphenylmethane-4,4'-diisocyanate, so that the molar ratio of is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com