A kind of lightweight flexible soft porcelain and preparation method thereof

A flexible and soft porcelain technology, applied in the field of soft porcelain, can solve the problems of low elongation at break, poor tear resistance, and insufficient flexibility, and achieve the effects of high elongation at break, high flame retardancy, and short half-life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

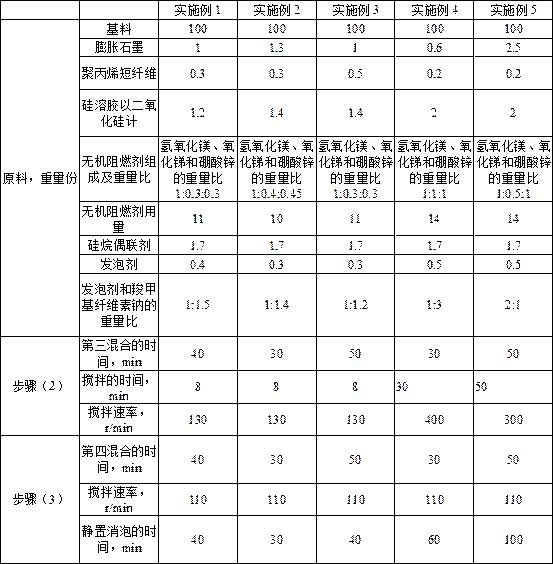

Examples

preparation example Construction

[0031] A second aspect of the present invention provides a method for preparing the described lightweight flexible soft porcelain, the method comprising:

[0032] (1) firstly mixing the base material, expanded graphite and polypropylene short fibers, and then adding silica sol, silane coupling agent and water for second mixing to obtain a mixture;

[0033] (2) Mix the foaming agent and the inorganic flame retardant for the third time, then introduce sodium carboxymethyl cellulose and water, and stir to obtain a foaming liquid;

[0034] (3) The mixture and the foaming liquid are mixed for the fourth time, and then left to stand for defoaming to form a paste. After injection molding, the second stand is performed, and then dehydrated.

[0035] In the present invention, in step (1), the conditions of the first mixing and the second mixing are not limited, as long as they can be fully mixed; for example, the mixing time is 20-60 min respectively.

[0036] According to the present...

Embodiment approach

[0041]According to a preferred embodiment of the present invention, the preparation method of the lightweight flexible soft porcelain comprises:

[0042] (1) firstly mixing the base material, expanded graphite and polypropylene short fibers, and then adding silica sol, silane coupling agent and water for second mixing to obtain a mixture;

[0043] With respect to the base material of 10 parts by weight, the consumption of the water is 70-100 parts by weight;

[0044] (2) The foaming agent and the inorganic flame retardant are mixed for a third time for 30-50 minutes, then sodium carboxymethyl cellulose and water are introduced, and the foaming liquid is obtained by stirring for 5-10 minutes;

[0045] With respect to 10 parts by weight of foaming agent and inorganic flame retardant, the amount of water used is 100-150 parts by weight;

[0046] (3) The mixture and the foaming liquid are subjected to the fourth mixing for 30-50min, the fourth mixing is carried out under stirring...

Embodiment 1

[0049] (1) The base material, expanded graphite, and polypropylene staple fibers are first mixed for 20 minutes, and then silica sol (concentration is 25wt%), silane coupling agent, and water are added for the second mixing for 20 minutes to obtain a mixture;

[0050] With respect to the base material of 10 parts by weight, the consumption of the water is 80 parts by weight;

[0051] (2) The foaming agent and the inorganic flame retardant are mixed for a third time for 30-50 minutes, then sodium carboxymethyl cellulose and water are introduced, and the foaming liquid is obtained by stirring for 5-10 minutes;

[0052] With respect to 10 parts by weight of foaming agent and inorganic flame retardant, the amount of water used is 120 parts by weight;

[0053] (3) The mixture and the foaming liquid are subjected to the fourth mixing for 30-50min, the fourth mixing is carried out under stirring, and the stirring rate is 100-150r / min; It is a paste, and after injection molding, it i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com