Mudguard supporting rod assembly and manufacturing method thereof

A manufacturing method and a technology for supporting rods, which are applied in the directions of superstructure sub-assembly, transportation and packaging, superstructure, etc., can solve the problem of mismatching working conditions of commercial vehicle fenders, high cost of plastic rod molds, and light weight. Low cost, high light weight and high strength of material composite structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the technical problems solved by the present invention, the technical solutions adopted and the technical effects achieved clearer, the technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

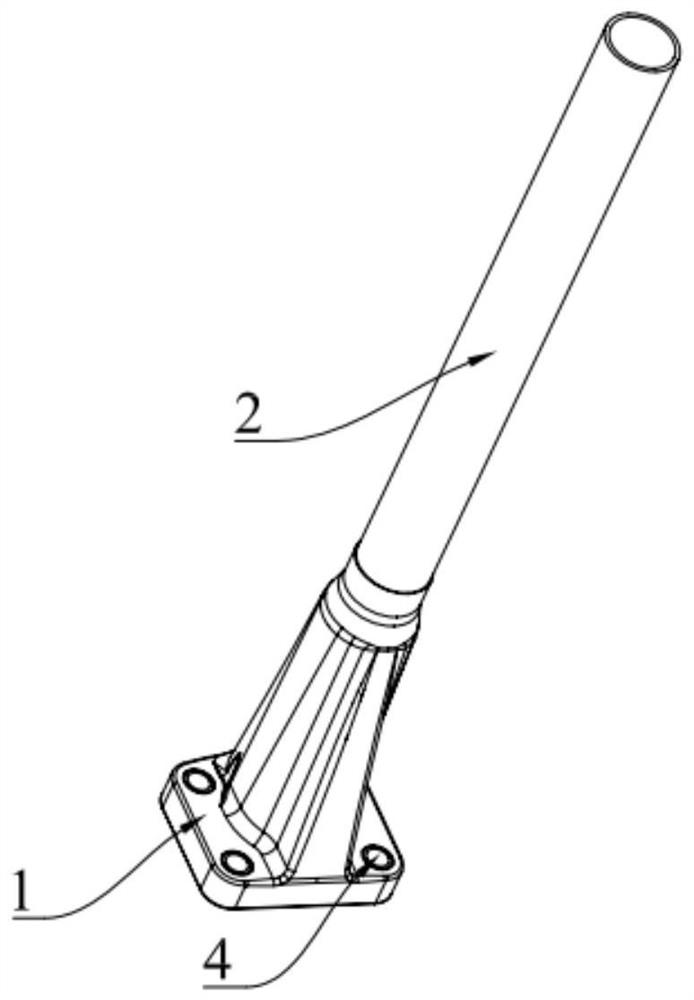

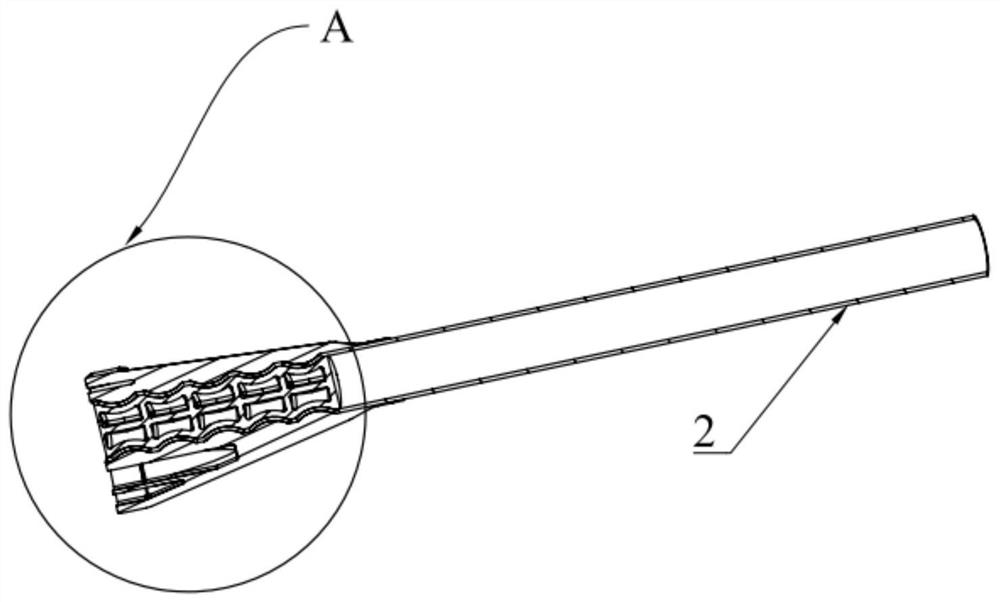

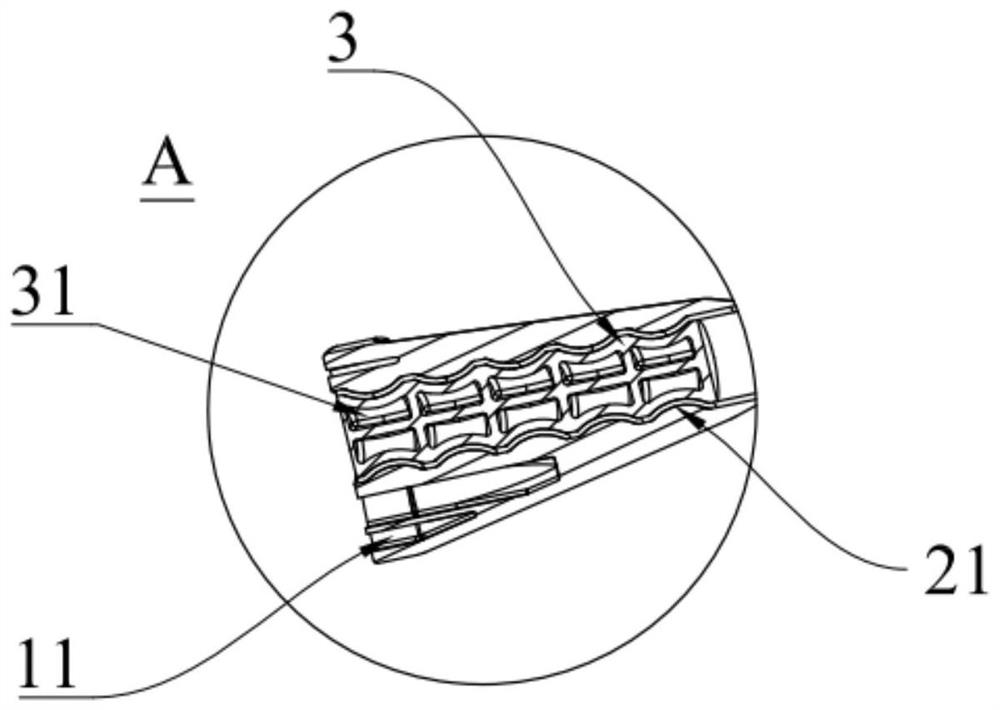

[0031] Refer below Figure 1 to Figure 6 The specific structure of the fender support rod assembly of the embodiment of the present invention is described.

[0032] Such as Figure 1 to Figure 3 as well as Figure 5 As shown, a fender support rod assembly includes a base 1, a support rod 2, a core 3 and a bushing 4, the base 1 and the core 3 are plastic parts, and the support rod 2 and the bushing 4 are aluminum Alloy parts, the base 1 is provided with a mounting hole 12, the bushing 4 is set in the mounting hole 12, the core body 3 and the mounting end 21 of the support rod 2 are in contact with each other and are located in the mounting end 21, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com