Slow-release antibacterial packaging material and preparation method thereof

A packaging material and slow-release technology, which is applied in the field of slow-release antibacterial packaging materials and its preparation, can solve the problems of poor thermal stability, limited utilization, and inability to combine mechanical properties, etc., to achieve durable and efficient antibacterial properties, simple and efficient processing, and The effect of good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

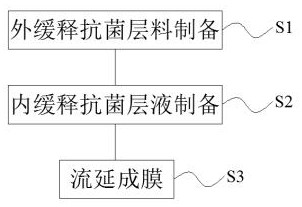

Method used

Image

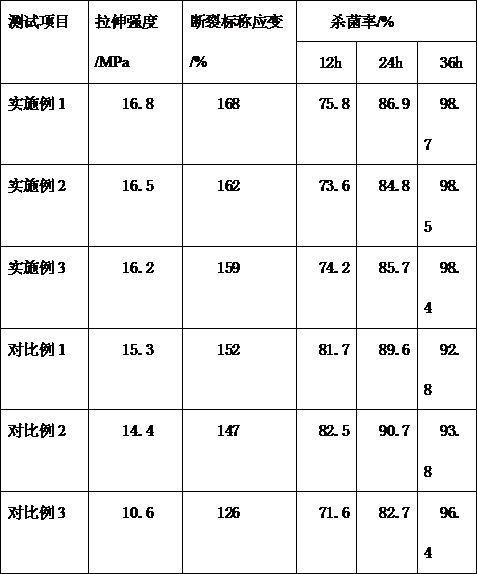

Examples

Embodiment 1

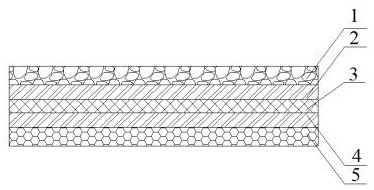

[0033]Such asFigure 1-2As shown, the sustained release of the present embodiment includes an outer sustained release antibacterial layer 1, a first barrier layer 2, an intermediate film layer 3, a second barrier layer 4, and a second barrier layer 5, from the outer to the outer to the outer to inward. The inner bucket of the antibacterial layer 5 is prepared from the weight of the following weight of the material: 85 parts of metallocene polyethylene resin, 18 parts of high density polyethylene resin, 35 cyclodextrin-essential oil classes, plasticizer 11 parts of alcohol, 8 servine sulfate. The first barrier layer 2, the second barrier layer 4 is prepared from a linear low density polyethylene resin with a high density polyethylene resin to be prepared according to 2.5: 1.

[0034]The method of preparing the cyclodextrin-essential oil clamper is as follows: β-cyclo paste is dissolved in distilled water, stir evenly to obtain a concentration of 5.2% by weight of β-cyclo-cyclo-hydrazine ...

Embodiment 2

[0041]Such asFigure 1-2As shown, the sustained release of the present embodiment includes an outer sustained release antibacterial layer 1, a first barrier layer 2, an intermediate film layer 3, a second barrier layer 4, and a second barrier layer 5, from the outer to the outer to the outer to inward. The inner bucket of the antibacterial layer 5 is prepared from the weight of the following weights: 83 parts of metallocene polyethylene resin, 17 high density polyethylene resins, 34 cyclodextrin-essential oil clam, plasticizer glucose 10 parts, 9 sodium lignozoate sodium sulfate. The first barrier layer 2, the second barrier layer 4 is prepared from a linear low density polyethylene resin with a high density polyethylene resin to be prepared according to 2.5: 1.

[0042]The method for preparing the cyclodextrin-essential oil clamper is as follows: β-cyclo paste is dissolved in distilled water, stir evenly to obtain a concentration of 5.2% by weight of β-cyclodecycle water solution, 60 °...

Embodiment 3

[0049]Such asFigure 1-2As shown, the sustained release of the present embodiment includes an outer sustained release antibacterial layer 1, a first barrier layer 2, an intermediate film layer 3, a second barrier layer 4, and a second barrier layer 5, from the outer to the outer to the outer to inward. The inner bucket of the antibacterial layer 5 is prepared from the weight of the following weight of the material: 86 parts of metallocene polyethylene resin, 18 parts of high density polyethylene resin, 35 cyclodextrin-essential oil clades, plasticizer glycerol 12 serviles, 9 serves sodium lignozoate. The first barrier layer 2, the second barrier layer 4 is prepared from a linear low density polyethylene resin to high density polyethylene resin.

[0050]The method for preparing the cyclodextrin-essential oil clam is as follows: β-cyclo paste is dissolved in distilled water, stir evenly to obtain a concentration of 6 wt% β-cyclo-cyclo-hydrazine solution, 60 ° C water bath heating 12min, n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com