Anti-mite and mite-killing ceramic tile and preparation method thereof

An anti-mite and ceramic tile technology, applied in the fields of botanical equipment and methods, acaricides, animal husbandry, etc., can solve problems such as mutual reference and differences, achieve strong controllability, simple operation steps, and be conducive to large-scale industrialization production effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

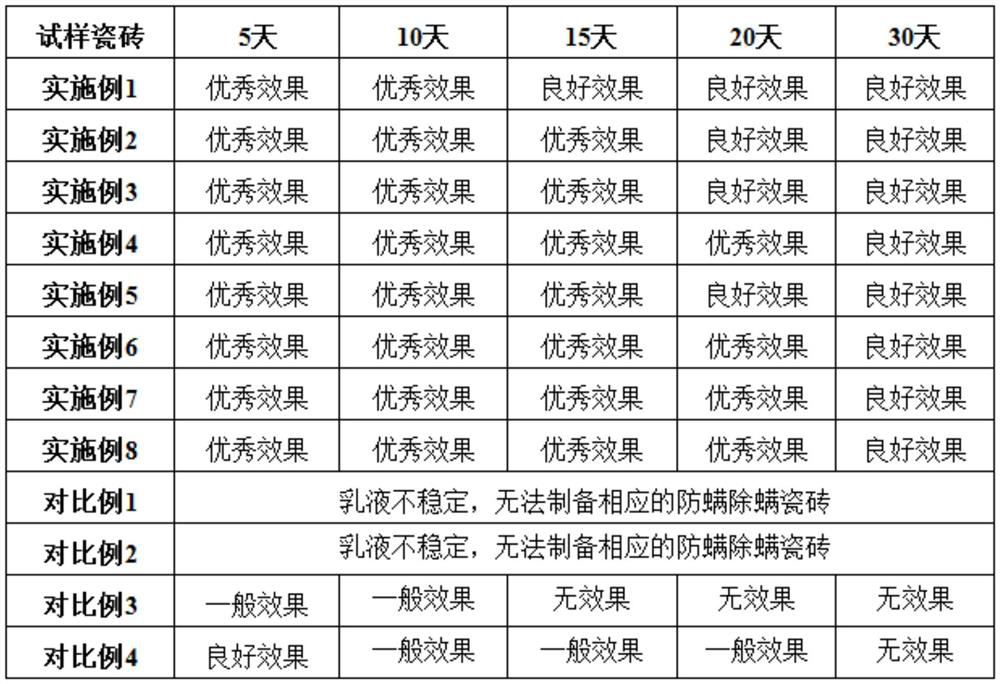

Examples

Embodiment 1

[0026] An anti-mite and mite-removing tile, which is composed of a tile body and an anti-mite and mite-removing slow-release film layer, and the anti-mite and mite-removing slow-release film layer is sprayed on the tile body after atomizing the anti-mite and mite-removing emulsion And formed by drying and curing, the raw material components of the anti-mite and mite-removing emulsion are composed of 7% anti-mite and mite-removing effective material, 7% film forming agent, 3% emulsifier, 1.5% anti-mite Contamination agent, 0.5% preservative and the balance of water whose hardness does not exceed 500ppm.

[0027] Wherein, the anti-mite and mite-removing effective substance is benzyl benzoate; the film-forming agent is polyvinyl alcohol; the emulsifier is polyoxyethylene monolaurate; the antifouling agent is nano silicon dioxide; The preservative is a mixture of isothiazolinone and methylisothiazolinone in a ratio of 3:1 in parts by weight.

[0028] Preparation:

[0029]1) Acco...

Embodiment 2

[0056] An anti-mite and mite-removing tile, which is composed of a tile body and an anti-mite and mite-removing slow-release film layer, and the anti-mite and mite-removing slow-release film layer is sprayed on the tile body after atomizing the anti-mite and mite-removing emulsion And formed by drying and curing, the raw material components of the anti-mite and mite-removing emulsion are composed of 5% anti-mite and mite-removing effective material, 12% film-forming agent, 2% emulsifier, 2% anti-mite Contamination agent, 0.2% preservative and the balance of water whose hardness does not exceed 500ppm.

[0057] Wherein, the anti-mite and mite-removing effective substance is cineole; the film-forming agent is hydroxyethyl cellulose; the emulsifier is polyoxyethylene lauryl ether; the antifouling agent is nano silicon dioxide; The preservative is a mixture of isothiazolinone and methylisothiazolinone in a ratio of 3:1 by weight.

[0058] Preparation:

[0059] 1) According to th...

Embodiment 3

[0062] An anti-mite and mite-removing tile, which is composed of a tile body and an anti-mite and mite-removing slow-release film layer, and the anti-mite and mite-removing slow-release film layer is sprayed on the tile body after atomizing the anti-mite and mite-removing emulsion And formed by drying and solidifying, the raw material components of the anti-mite and mite-removing emulsion consist of 8% anti-mite and mite-removing effective substance, 3% film-forming agent, 5% emulsifier, 0.5% anti-mite Contamination agent, 0.5% preservative and the balance of water whose hardness does not exceed 500ppm.

[0063] Wherein, the anti-mite and mite-removing effective substance is citronellal; the film-forming agent is hydroxyethyl cellulose; the emulsifier is polyoxypropylene lanolin; the antifouling agent is nano silicon dioxide; The preservative is a mixture of isothiazolinone and methylisothiazolinone in a ratio of 3:1 in parts by weight.

[0064] Preparation:

[0065] 1) Acco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com