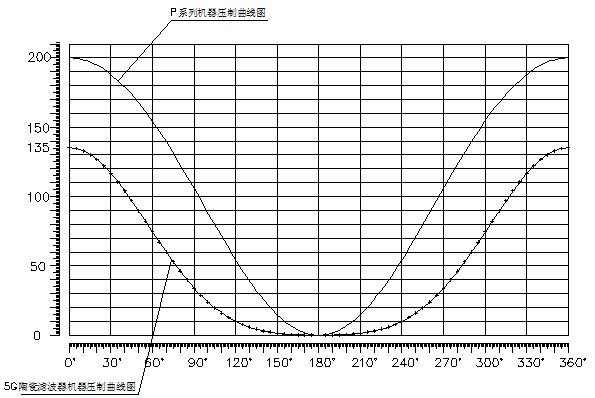

Pressing principle and mechanism of powder pressing machine special for 5G ceramic filter forming

A ceramic filter and powder technology, applied in ceramic molding machines, manufacturing tools, auxiliary molding equipment, etc., can solve the problems of inability to meet high density uniformity, insufficient pressure holding time, low energy utilization rate, etc., and achieve short torque , Small elastic after-effect, energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

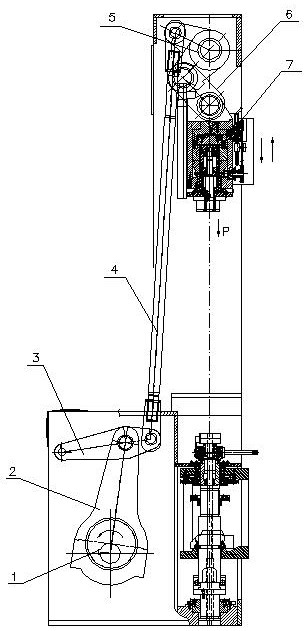

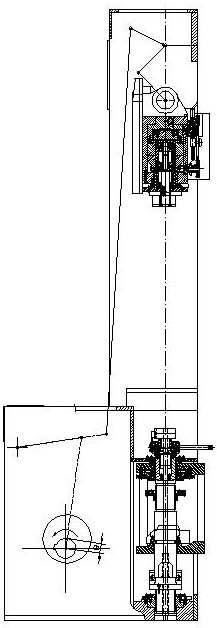

[0018] A pressing principle and mechanism of a powder press dedicated to forming 5G ceramic filters. The pressing structure includes an eccentric cam 1, a first connecting rod 2, a lever 3, a pull rod 4, an upper crank 5, and a second connecting rod 6 and upper punch seat 7;

[0019] The eccentric cam 1 is arranged at the bottom of the pressing mechanism. The eccentric cam 1 is connected with an external motor and a reducer, and is driven by the external motor and reducer to rotate counterclockwise. The upper part of the eccentric cam 1 is connected to The first connecting rod 2, the upper part of the first connecting rod 2 is connected to the lever 3, one end of the lever 3 is connected to the lower end of the pull rod 3, the upper end of the pull rod 3 is connected to the upper crank 5, and the first connecting rod 3 is connected to the upper crank 5. The second connecting rod 6 is arranged under the upper crank 5 and connected with the upper crank 5 , and the upper punch se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com