A nozzle rotating dual-nozzle cement 3D printing structure and its application method

A 3D printing and nozzle-type technology, which is applied in the direction of cement mixing devices, chemical instruments and methods, cleaning methods and appliances, etc., can solve problems such as uneven cement pouring, low degree of automation, and affecting construction quality, so as to ensure printing performance. , high flexibility of use, and the effect of improving printing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

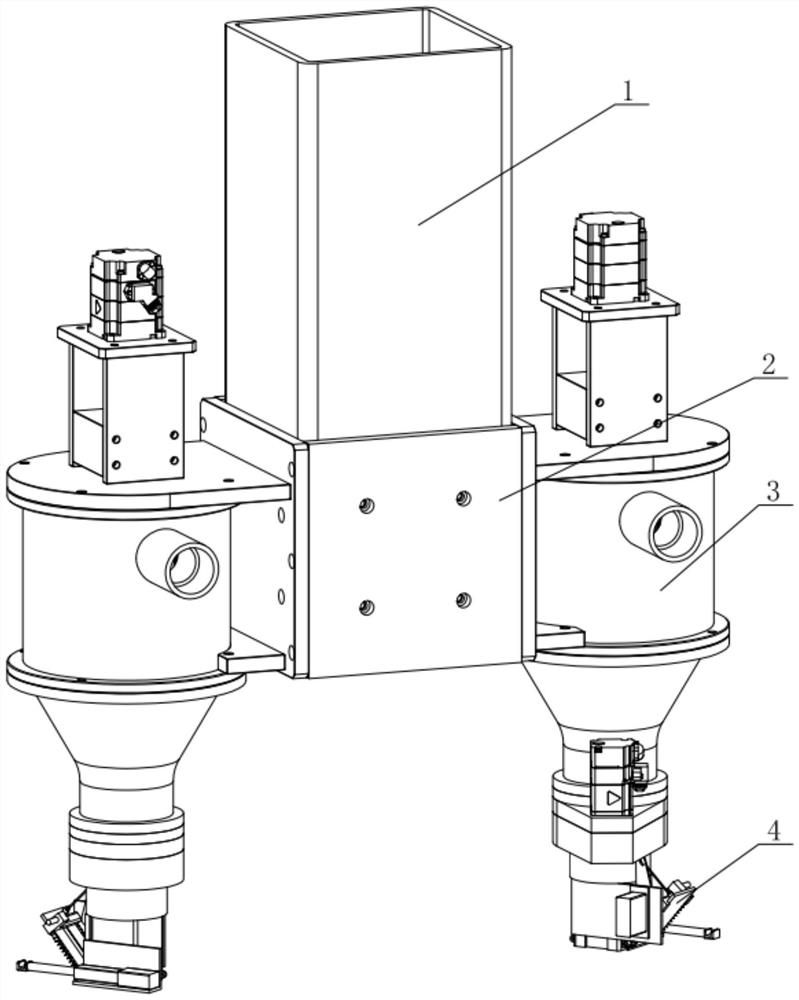

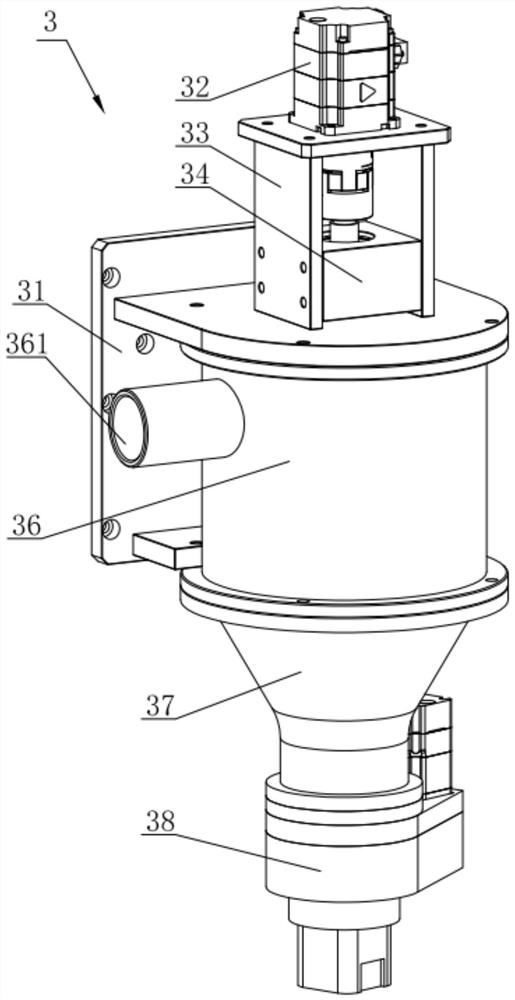

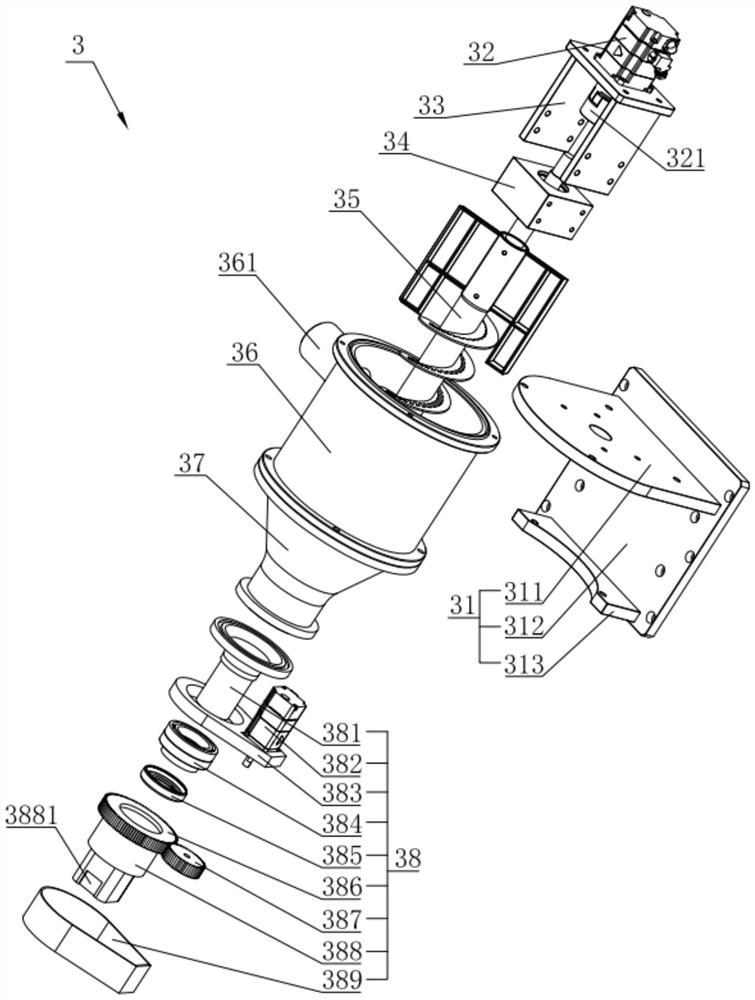

[0040] Such as figure 1 As shown, a nozzle rotating dual-nozzle cement 3D printing structure in this embodiment includes a column 1, and a nozzle assembly 3 is symmetrically installed on the side of the column 1; figure 2 , image 3 and Figure 4 As shown, the structure of the single group nozzle assembly 3 is as follows: it includes a support base 31 fixed on the side of the column 1, a feed cylinder 36 is fixed on the outside of the support base 31, a motor base 33 is installed above the feed cylinder 36, and the motor base 33 A feeding motor 32 is installed on the top, the output end of the feeding motor 32 faces down and a screw shaft 35 is installed at the end, and the screw shaft 35 extends downward into the feeding barrel 36; the bottom of the feeding barrel 36 is equipped with a connected extrusion barrel 37. The bottom of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com