Multi-layer gluing and composite process of antibacterial plywood

A composite process and multi-layered technology, which is applied in the jointing of wooden veneers, glue guns, manufacturing tools, etc., can solve the problems of easy to increase viscosity, excessive addition, and large volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] A multi-layer gluing composite process for antibacterial plywood, the specific process is as follows: add dodecyltrimethylammonium chloride into water and stir to dissolve, configure it as a treatment agent solution with a concentration of 3%, and then cut it into a certain amount according to requirements. Large and small wood veneers are dried until the water content is less than 5%, and the dried wood boards are soaked in the treatment agent solution for 10-20 minutes, and placed on a multi-layer gluing compound device for gluing processing after drying;

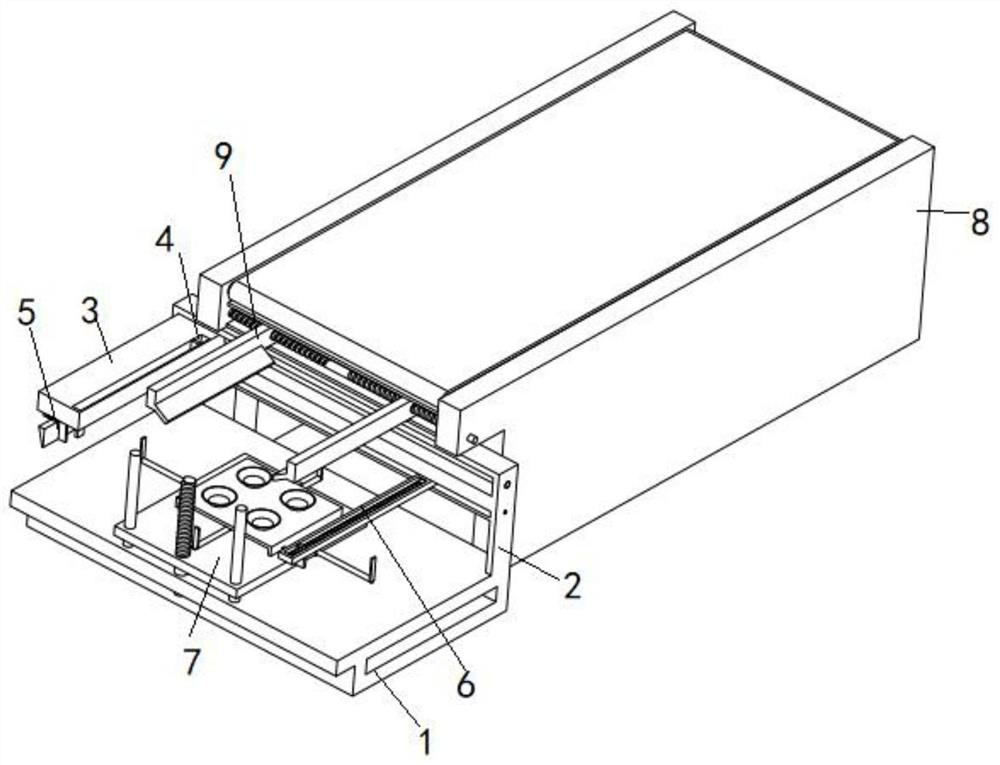

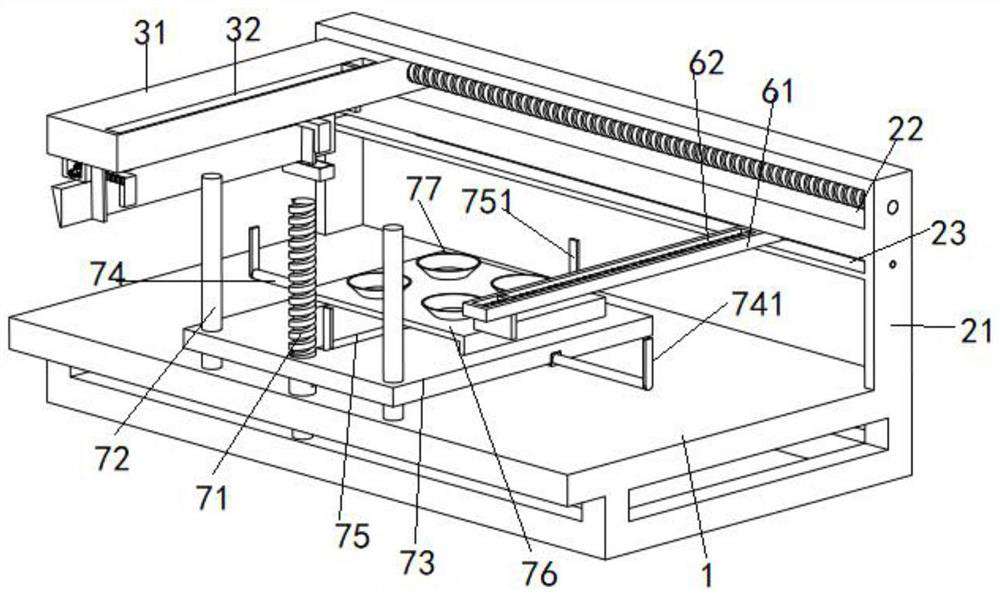

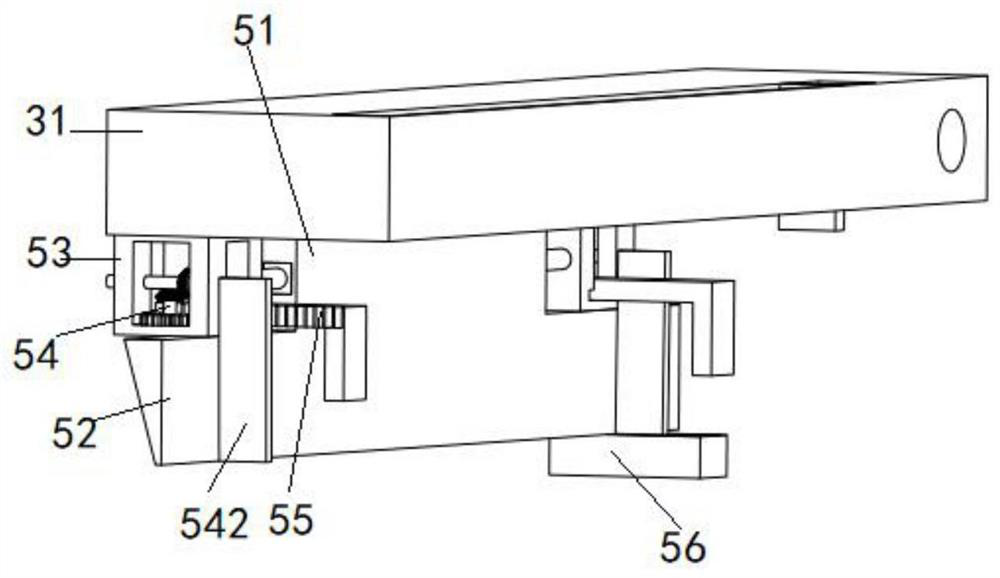

[0031] Such as figure 1 and figure 2 As shown, wherein the multi-layer gluing composite device includes a gluing processing table 1, a positioning and fixing seat 2 is arranged on one side of the surface of the gluing processing table 1, and a sliding mounting seat 3 is slidably installed on the positioning and fixing seat 2, and one part of the sliding mounting seat 3 A glue spreading component 4 is installed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com