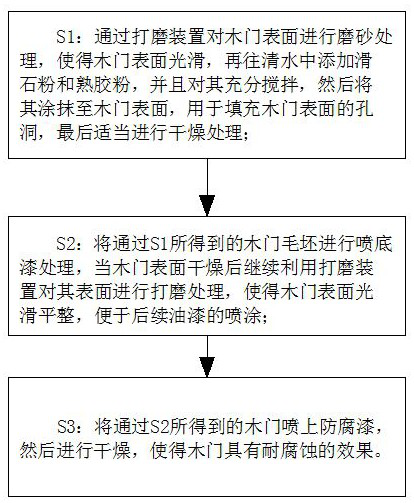

A kind of corrosion-resistant wooden door processing technology

A processing technology and corrosion-resistant technology, used in metal processing equipment, manufacturing tools, grinding workpiece supports, etc., can solve the problems of poor grinding effect of wooden doors, easy peeling of paint on the surface of wooden doors, affecting the corrosion resistance of wooden boards, etc., to achieve smooth sliding , the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

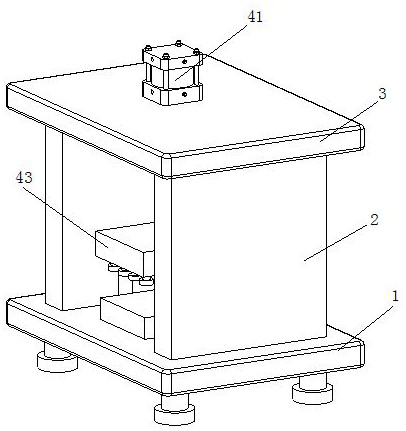

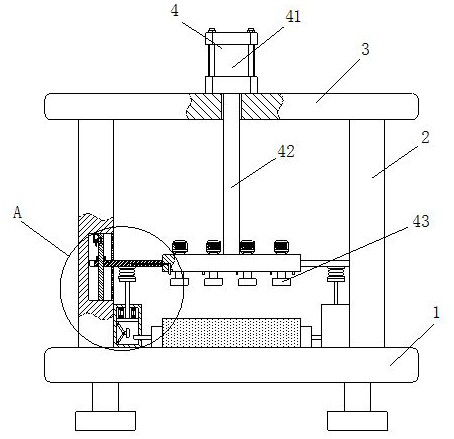

[0032]As an embodiment of the present invention, the top of the workbench 1 is further provided with a fixing mechanism; the fixing mechanism includes a sliding plate 51, a No. 1 housing 52, an I-shaped plate 53, a No. 1 connecting rod 54, a No. 2 connecting rod The rod 55, the connecting plate 56, the No. 2 push rod 57 and the pressing plate 58; the sliding plate 51 is symmetrically fixed on the side wall of the grinding disc 43; the No. 1 housing 52 is symmetrically fixed on the top of the workbench 1; the The I-shaped plate 53 is slidably connected to the inner wall of the No. 1 housing 52; one end of the No. 1 connecting rod 54 is hinged to the bottom of the I-shaped plate 53, and the other end is hinged to the connecting plate 56; one end of the No. 2 connecting rod 55 It is hinged to the bottom inner side wall of the No. 1 housing 52 , and the other end is hinged to the connecting plate 56 ; the No. 2 push rod 57 is arranged through the side wall of the No. connection; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com