Stamping machine tool with buffering function

A stamping machine tool and functional technology, applied in the field of machine tools, can solve the problems of staff discomfort, looseness, and failure to achieve the buffering effect, and achieve the effect of avoiding the enlargement of the aperture and avoiding the impact force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

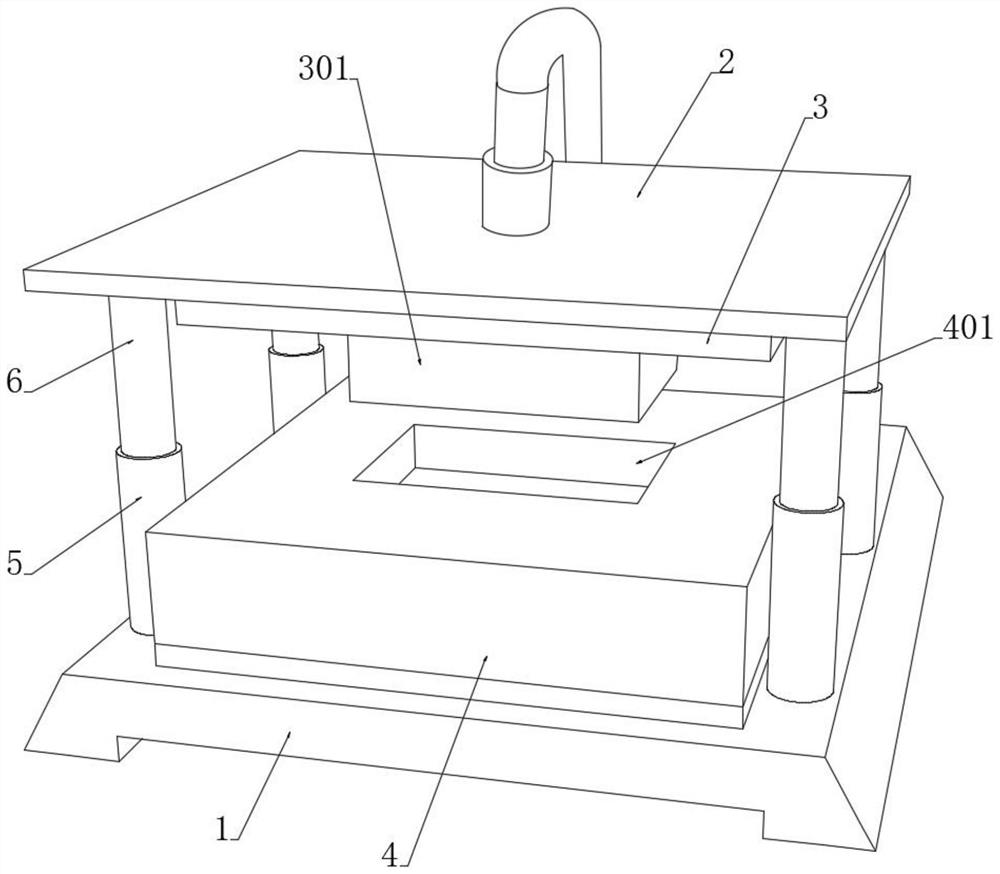

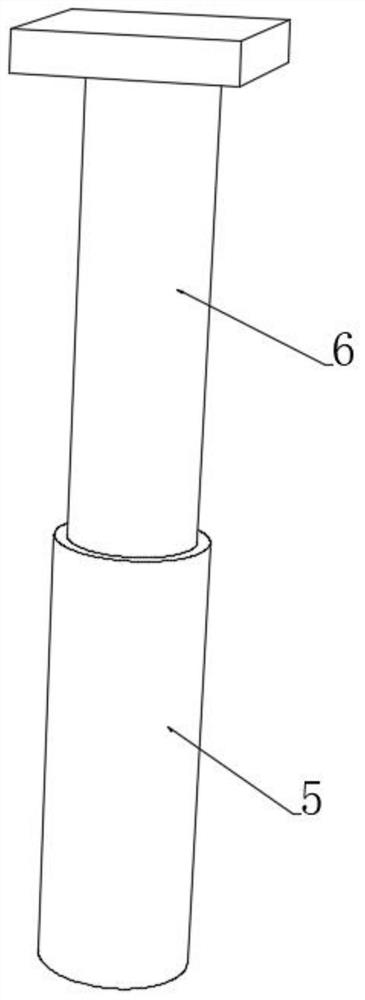

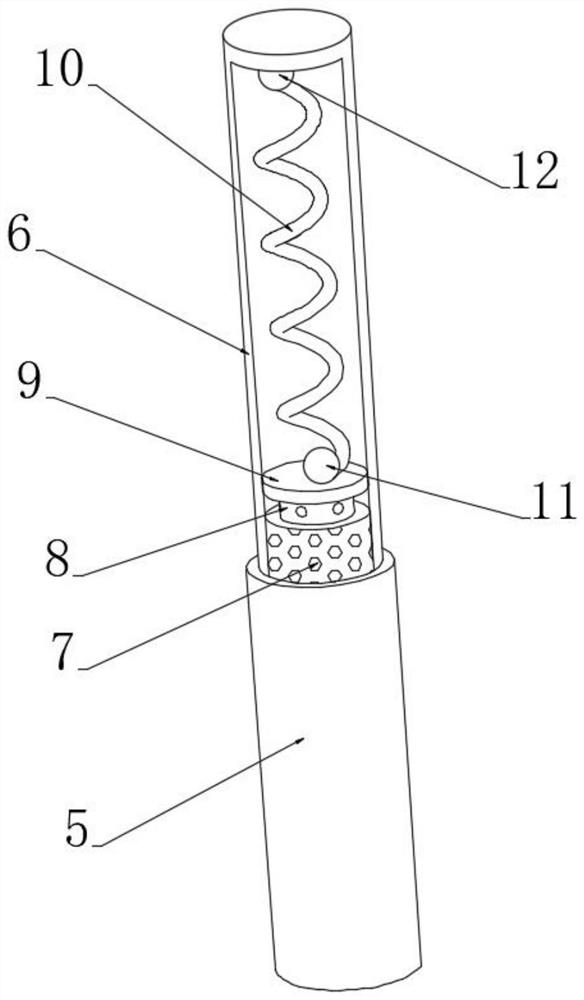

[0041] see figure 1 , a stamping machine tool with a buffer function, comprising a lower die base 1 and an upper die base 2 distributed up and down, the upper end of the rear side of the lower die base 1 is fixedly connected with a stamping device for stamping the upper die base 2, and the upper die base 2 The bottom end of the upper mold 3 is provided with an upper mold 3, the top of the lower mold base 1 is provided with a lower mold 4, the upper end of the lower mold 4 is provided with a die 401, and the bottom end of the upper die 3 is provided with a punch 301 that matches the die 401 , the stamping equipment is a stamping head fixedly installed on the top of the upper die base 2, the punching head is installed on the rear end wall of the lower die base 1 through a mechanical arm, and the technician places the workpiece to be stamped on the die on the lower die 4 At 401, the upper die base 2 is pressed down by an external stamping device. After the upper die base 2 is pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com