A linear guide rail translation mechanism

A translation mechanism, linear guide technology, applied in the direction of electromechanical devices, control mechanical energy, electrical components, etc., can solve the problems of low transmission efficiency, cumbersome and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

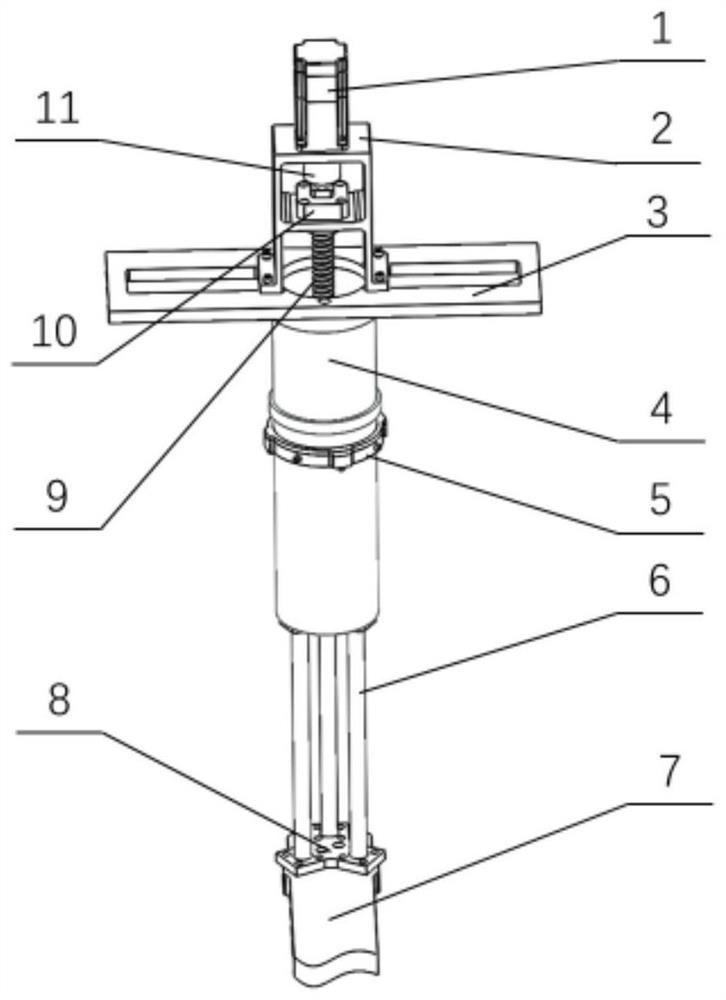

[0028] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

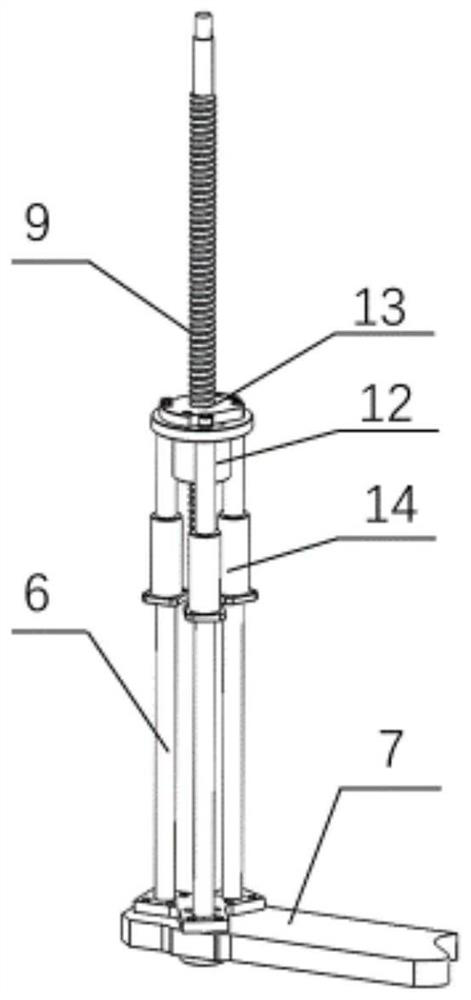

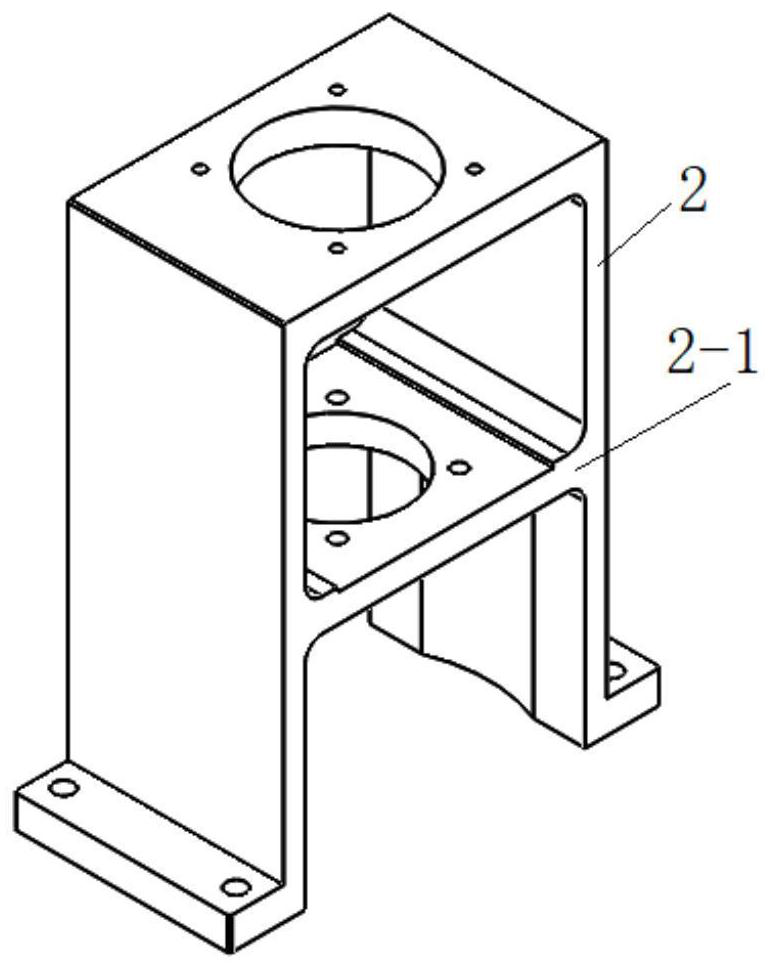

[0029] see figure 1 and figure 2 , the present invention provides a linear guide rail type translation mechanism with the characteristics of flexibility, portability, high transmission efficiency and good stability, aiming at the fact that the transmission efficiency of the mechanism for vertical translation movement in the field of industrial machinery manufacturing is low and relatively heavy. , in the linear guide rail translation mechanism of the present invention, such as image 3 As shown, the motor support 2 has a U-shaped structure as a whole, with the opening facing downwards, and a mounting plate 2-1 is fixedly arranged between the two wings of the motor support 2; Figure 4 As shown, the bracket fixing plate 3 is a plate-like structure, and there are mounting holes and bolt holes enough to install other parts; Figure 5 and Figure 6 As s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com