Novel large-diameter aluminum alloy pipe reshaping device

A large-diameter, aluminum alloy technology is applied in the field of new large-diameter aluminum alloy pipe orthopedic devices, which can solve the problems of inconvenient use, unfavorable economic benefits of aluminum alloy pipes, and high operating experience requirements, and achieve convenient use, improve orthopedic effect, and improve economic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

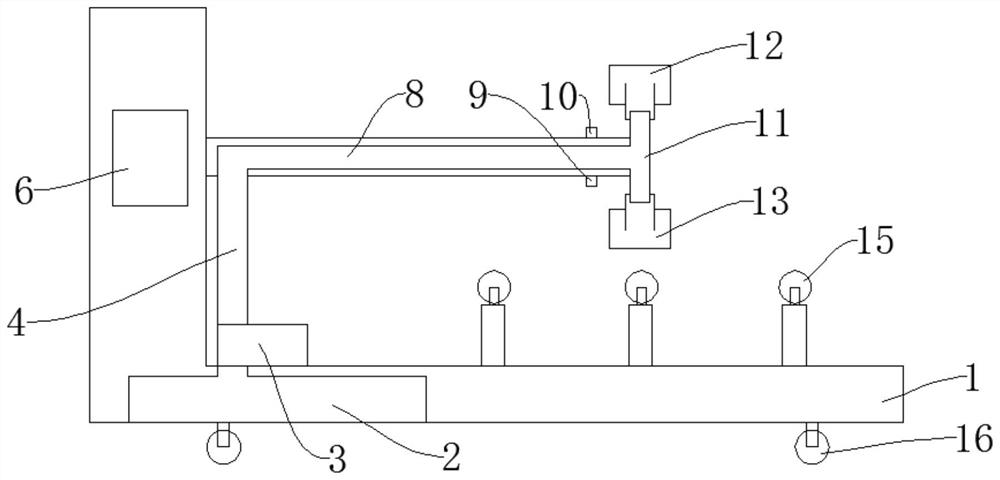

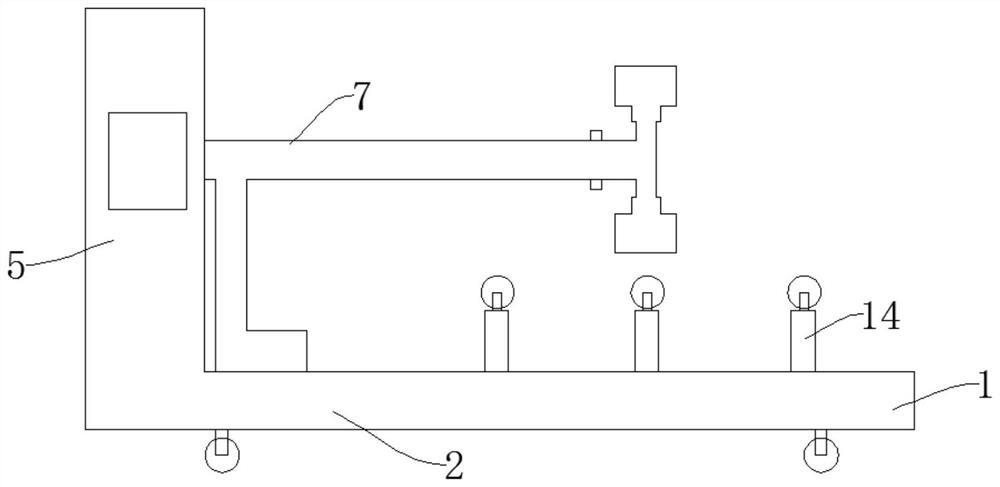

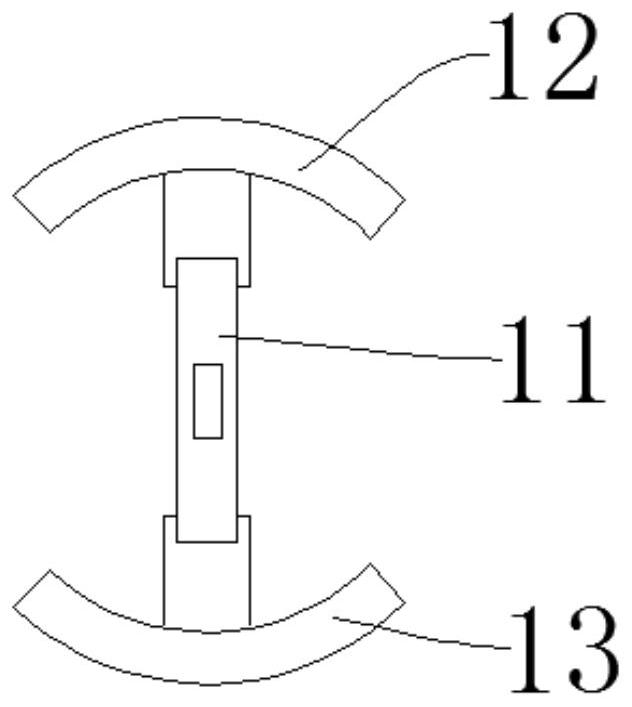

[0020] The present invention will be further described below in conjunction with accompanying drawing:

[0021] Such as Figure 1-Figure 3 As shown, a new large-diameter aluminum alloy pipe orthopedic device includes a counterweight base 1, a hydraulic oil pump 3, a two-way hydraulic cylinder 11, an upper correction head 12 and a lower correction head 13, and a hydraulic oil tank is arranged inside the counterweight base 1 2. Bottom moving rollers 16 are arranged under the counterweight base 1 to facilitate the movement of the device. A hydraulic oil pump 3 is arranged above the counterweight base 1. The hydraulic oil pump 3 provides power for the two-way hydraulic cylinder 11. There is a column 5, a distance measuring display 6 is arranged on one side of the column 5, and the distance measuring display 6 is used to display the measurement results of the upper rangefinder 10 and the lower rangefinder 9, and an upper oil pipe 4 is arranged above the hydraulic oil pump 3, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com