Pain relieving capsule preparation equipment

A technology for capsule preparation and pain relief, which is applied in the direction of dispersed particle separation, dispersed particle filtration, solid separation, etc. It can solve the problems that the fan is easily blocked by the capsule and the capsule screening efficiency is low, and achieves low price, high efficiency, economical and practical Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The following is further described in detail through specific implementation methods:

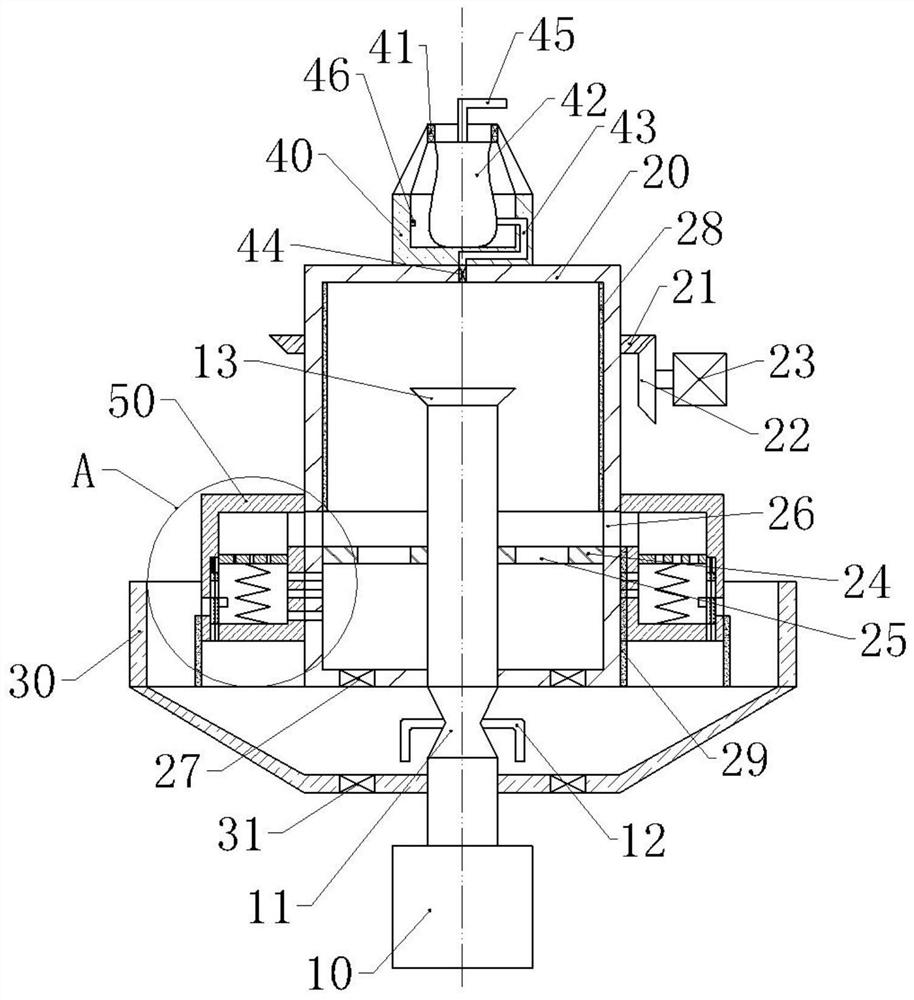

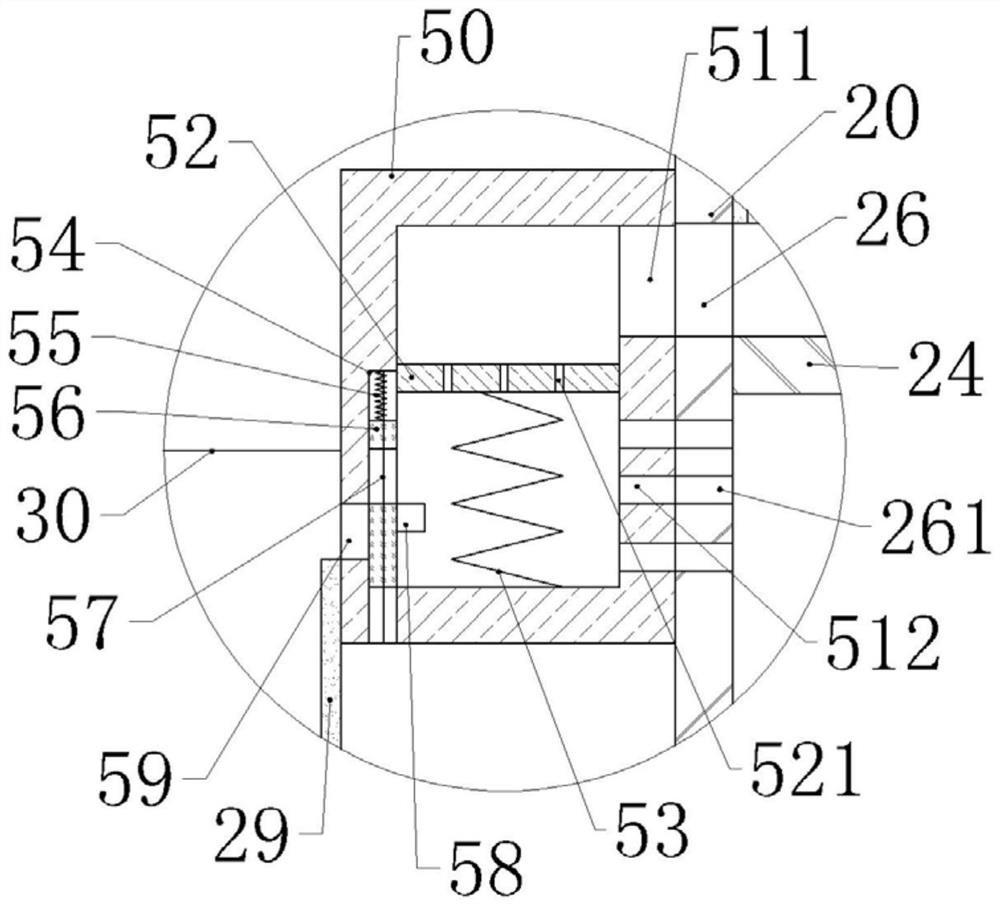

[0035] The reference signs in the accompanying drawings of the description include: blower 10, Venturi tube 11, suction pipe 12, diffusion cover 13, drum 20, first bevel gear 21, second bevel gear 22, motor 23, turntable 24, first pass Hole 25, second through hole 26, sixth through hole 261, first automatic valve 27, first grinding cylinder 28, second grinding cylinder 29, fixed bucket 30, second automatic valve 31, housing box 40, fixed ring 41 , cloth bag 42, vacuum pipe 43, one-way valve 44, exhaust pipe 45, push switch 46, fixed box 50, third through hole 511, fourth through hole 512, slide plate 52, fifth through hole 521, first The spring 53 , the T-shaped chute 54 , the second spring 55 , the T-shaped slider 561 , the seventh through hole 57 , the pressing block 58 , and the eighth through hole 59 .

[0036] The embodiment is basically as attached figure 1 - attached figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com