Anti-corrosion treatment process for carbon steel plate equipment in environmental protection industry

An anti-corrosion treatment and steel plate technology, applied in anti-corrosion coatings, special surfaces, and devices for coating liquids on surfaces, etc. It can solve the problems of different cold and heat deformation, peeling, and bulging of carbon steel plates and anti-corrosion coatings, so as to prevent bulging. and delamination phenomenon, cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

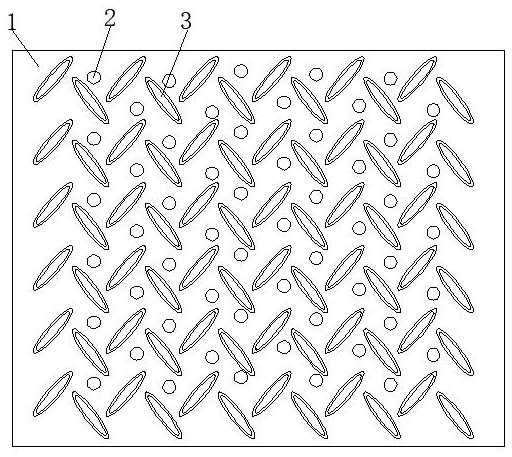

[0021] Such as figure 1 As shown, the embodiment of the present invention provides an anti-corrosion treatment process for carbon steel plate equipment in the environmental protection industry, including the following process:

[0022] Step 1: Choose an alternative material for the box body of the plastic-fired plate dust collector

[0023] Use the embossed carbon steel plate 1 as the manufacturing material of the plastic-burned plate dust collector box, and then clean the surface of the embossed carbon steel plate 1;

[0024] Step 2: punch holes

[0025] Microholes 2 run through the embossed carbon steel plate 1, the diameter of the microholes 2 is not more than 3 mm, the distribution of the microholes 2 is at least 20 per square meter, the distribution of the microholes 2 is uniform, and it is better to avoid the embossed protrusions 3 , which facilitates drilling and improves machinability;

[0026] Step 3: Brush anti-corrosion material

[0027] Brush the resin evenly o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com