A kind of hydrogenation pretreatment catalyst and its preparation method and application

A hydrogenation pretreatment and catalyst technology, applied in the direction of catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of catalyst pore structure performance degradation, etc., to avoid local coking, reduce migration, increase The effect of surface hydrophobicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

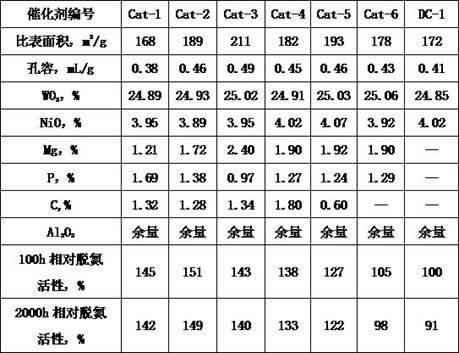

Embodiment 1

[0044] Weigh the powder according to the fact that the alumina powder a accounts for 30% of the total alumina weight. Calculating that magnesium oxide accounts for 4% of the weight of alumina powder a, weigh magnesium citrate to prepare an aqueous solution, and impregnate alumina powder a in equal volume; calculate that phosphorus accounts for 3.5% of the weight of alumina powder b, weigh ten The octaalkyl phosphate is configured into an aqueous solution, and an equal volume of alumina powder b is impregnated. The alumina powder loaded with additives was dried at 90°C for 18 hours. The alumina powder modified by the two additives was mixed with 2.3% of citric acid and 3.6% of the weight of the alumina, and then added to the acidic solution. The concentration of nitric acid in the acidic solution was 2.3wt%, and the rest was distilled water. Mix in a kneader for 15 minutes to form a plastic body and extrude into 1.7mm clover strips. The molding material was dried at 110° C. f...

Embodiment 2

[0046] Weigh the powder according to the alumina powder a accounting for 43% of the total alumina weight. Other subsequent steps were the same as in Example 1 to obtain catalyst Cat-2.

Embodiment 3

[0048] Weigh the powder according to the fact that the alumina powder a accounts for 60% of the total alumina weight. Other subsequent steps were the same as in Example 1 to obtain catalyst Cat-3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com