Method and device for preparing porous adsorption material by magnetic control nano motor cluster gel method

A technology of porous adsorption material and gel method, which is applied in the field of solid waste recycling and preparation of adsorption materials, can solve the problems of secondary pollution and poor effect, and achieves reduction of motion resistance, increase of specific surface area, and high thermal stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1: The method for preparing high-quality adsorption materials by the cluster gel method of magnetic nanoparticles and smelting slag, the specific content is as follows:

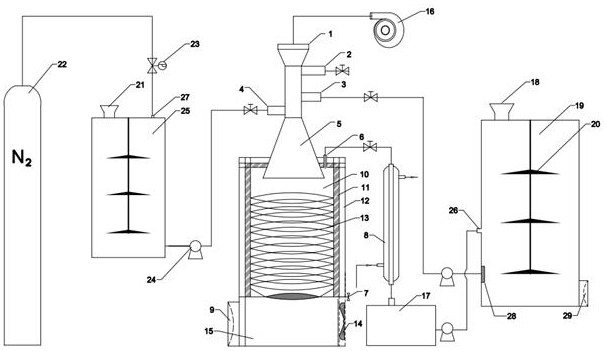

[0038] 1. If figure 1 As shown, the device of the method for preparing the porous adsorption material by the magnetically controlled nanomotor cluster gel method comprises a Venturi nozzle 5, a condensation device 8, a reactor 10, a magnetic field generator 13, an alcohol-acid organic mixture reservoir 17, a mixed reaction Device I19, nitrogen bottle 22, mixing reactor II25, nitrogen bottle 22 is connected with the N on the mixing reactor II25 through the pressure control switch 23 2 The air inlet 27 is connected, and the top of the mixing reactor II25 has a feed inlet II21, and the mixing reactor II25 is respectively provided with agitators, and the mixing reactor II25 is connected with the feed inlet I4 of the Venturi nozzle 5 through a pump, and the Venturi nozzle The nozzle 5 is also pr...

Embodiment 2

[0043] Embodiment 2: The method for preparing high-quality adsorption materials by the cluster gel method of magnetic nanoparticles and smelting slag is as follows:

[0044] The device structure of this embodiment is the same as that of Embodiment 1;

[0045] When in use, 20nm magnetic ferroferric oxide nanoparticles are made into an aqueous dispersion with a mass concentration of 3%, and the aqueous dispersion of magnetic nanoparticles, ethanol, and concentrated ammonia water are fully mixed at a volume ratio of 1:6:0.3 to prepare Obtain the mixture, press the magnetic nano particle aqueous dispersion: tetraethyl orthosilicate volume ratio is the ratio of 20:1, the mixture is put into mixing reactor II 25, and N 2Pass into the reactor 25 from the air inlet 27 and purge for 10 minutes, then add tetraethyl orthosilicate in 3 times, and fully stir for 30 minutes each time to obtain a silicon-coated magnetic micro-nano particle solution; at the same time, an aluminum smelter The...

Embodiment 3

[0049] Embodiment 3: The method for preparing high-quality adsorption materials by the cluster gel method of magnetic nanoparticles and smelting slag is as follows:

[0050] The device structure of this embodiment is the same as that of Embodiment 1;

[0051] When in use, 10nm magnetic ferric ferric oxide nanoparticles are made into an aqueous dispersion with a mass concentration of 4%, and the magnetic nanoparticle aqueous dispersion, ethanol, and concentrated ammonia water are fully mixed in a volume ratio of 1:8:0.4 to prepare Obtain the mixture, press the magnetic nano particle aqueous dispersion liquid: tetraethyl orthosilicate volume ratio is the ratio of 30:1, the mixture is put into mixing reactor II 25, and N 2 Pass into the reactor 25 from the air inlet 27 and purge for 10 minutes, then add tetraethyl orthosilicate in 3 times, and fully stir for 30 minutes each time to obtain a silicon-coated magnetic micro-nano particle solution; at the same time, a copper smelter ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com