Cavitation and microwave coupled milk protein concentrate treatment device

A technology of concentrated milk protein and processing device, which is applied in the field of protein product production, can solve the problems of simple cavitation generating device and does not reduce the viscosity of concentrated milk protein, and achieves enhanced cavitation effect, improved cavitation efficiency, and enhanced cavitation. Effects of primary effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

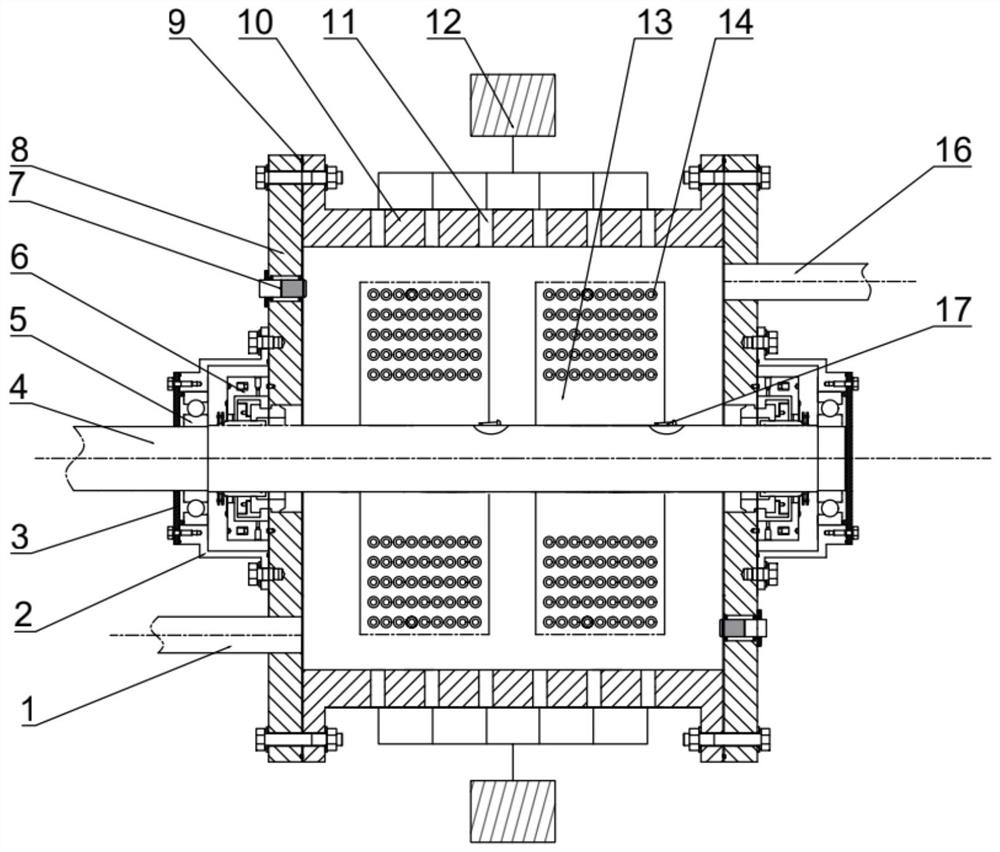

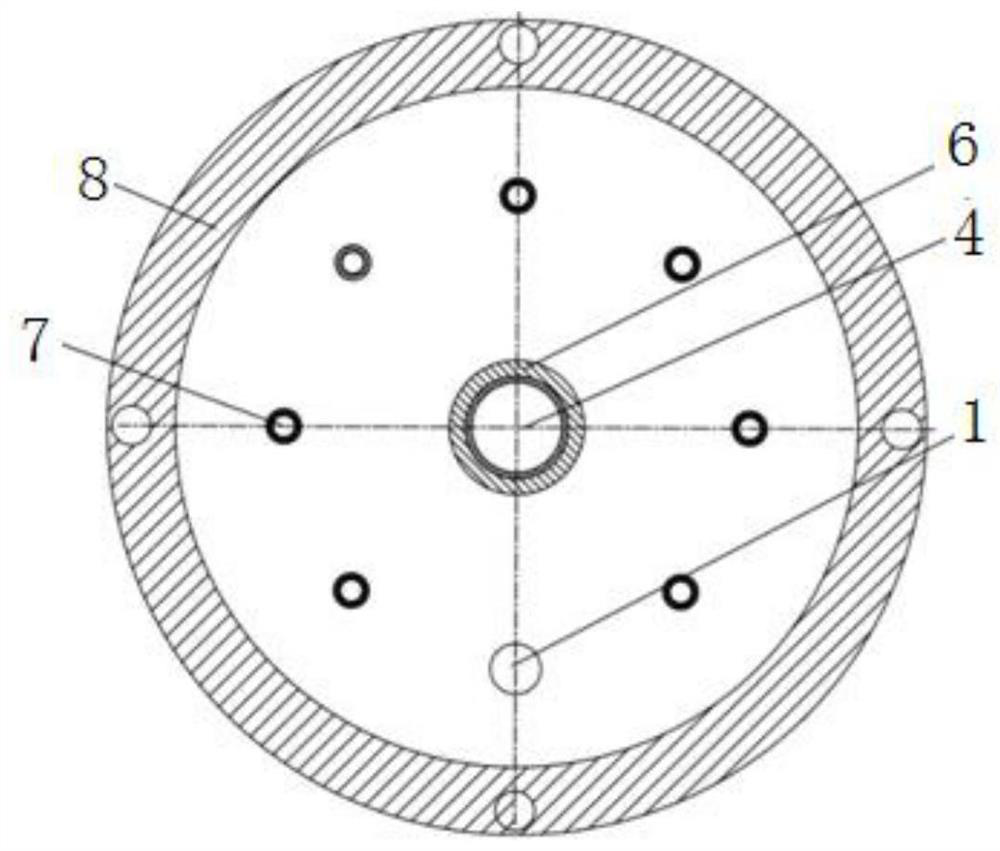

[0042] The concentrated milk protein processing device coupled with cavitation and microwave of the present invention can concentrate milk protein by coupling hydraulic cavitation, ultrasonic cavitation and microwave technology to increase viscosity. Its structure is as follows: figure 1 and figure 2 As shown, it includes a stator 10 , a rotor 13 , a rotating shaft 4 , a microwave generator 7 and an ultrasonic transducer 11 .

[0043] The stator 10 is a hollow sealed cylinder, the two ends of which are connected to the stator end cover 8 by bolts, and there is a sealing gasket 9 at the joint, so that a sealed cavity is formed inside the stator 10 . The stator end cover 8 is provided with an angular contact ball bearing 5 inside, and a sealing cover 2 is provided outside. The sealing cover 2 is connected to the sealing end cover 3, and a sealing ring 9 is provided at the connection to form a sealing structure. The inner diameter of the stator 10 is 300-600 mm, the width of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com