Granular aerosol generating product and rolling forming method thereof

An aerosol generation and molding method technology, applied in the manufacture of cigarettes, applications, tobacco, etc., can solve the problems of large differences, inability to cope with mass production and sales, and low production efficiency, and achieve low cost, firm plugging, and Ensure the effect of breathability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

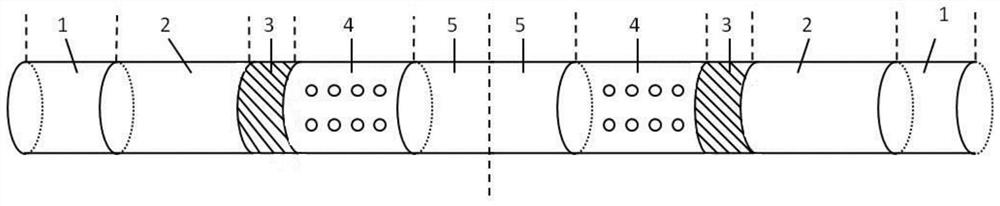

[0032] A particulate aerosol-generating product such as figure 1 As shown, through the binary compound nozzle rod forming machine, the nozzle rod segment wrapped in forming paper (including 1 acetate fiber nozzle rod, 2 cavity, 3 cooling material), the particle segment (4 tobacco particles), the thin film wrapped in forming paper Fragment (5 ordered tobacco flakes) is formed by coiling of 6 wrapping papers (tipping paper), and its coiling molding method comprises the following steps:

[0033] 1) On the nozzle rod forming machine, wrap 1 acetate fiber nozzle rod (length 10mm), 2 cavity (length 12mm), 3 cooling material (length 7mm) in the forming paper with water-based glue to form a heating device with cooling effect Non-burn cigarette mouthpiece rod segments;

[0034] 2) On the mouth rod forming machine, wrap 5 ordered thin slices (length 4mm) in the forming paper with water-based glue to form a thin segment with tobacco particle sealing effect;

[0035] 3) On the mouth sti...

Embodiment 2

[0044] A particulate aerosol-generating product such as figure 1 As shown, through the binary compound nozzle rod forming machine, the nozzle rod segment wrapped in forming paper (including 1 acetate fiber nozzle rod, 2 cavity, 3 cooling material), the particle segment (4 tobacco particles), the thin film wrapped in forming paper Fragment (5 ordered flakes) is formed by coiling of 6 wrapping papers (trademark paper), and its coiling forming method comprises the steps:

[0045] 1) On the nozzle rod forming machine, wrap 1 acetate fiber nozzle rod (length 10mm), 2 cavity (length 12mm), 3 cooling material (length 7mm) in the forming paper with water-based glue to form a heating device with cooling effect Non-burn cigarette tip rod segments;

[0046] 2) On the mouth rod forming machine, wrap 5 ordered thin slices (length 4mm) in the forming paper with water-based glue to form a thin segment with the sealing effect of tobacco particles;

[0047] 3) On the mouth rod forming machin...

Embodiment 3

[0056] A particulate aerosol-generating product such as figure 1 As shown, through the binary compound nozzle rod forming machine, the nozzle rod segment wrapped in forming paper (including 1 acetate fiber nozzle rod, 2 cavity, 3 cooling material), the particle segment (4 tobacco particles), the thin film wrapped in forming paper Segment (5 orderly flakes) is formed by coiling of 6 wrapping papers (tipping paper), and its coiling forming method comprises the following steps:

[0057] 1) On the mouth rod forming machine, wrap 1 acetate fiber nozzle rod (length 10mm), 2 cavities (length 14mm), and 3 cooling materials (length 8mm) in the forming paper with water-based glue to form a heating device with cooling effect Non-burn cigarette tip rod segments;

[0058] 2) On the mouth rod forming machine, wrap 5 ordered thin slices (5 mm in length) in the forming paper with water-based glue to form a thin segment with the sealing effect of tobacco particles;

[0059] 3) On the mouth r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com