Portable weeding machine for maintenance of mulberry tree

A portable, weeding machine technology, used in applications, harvesters, mechanical equipment, etc., can solve problems such as unusable, insufficient power, and achieve the effect of enhancing shock resistance and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

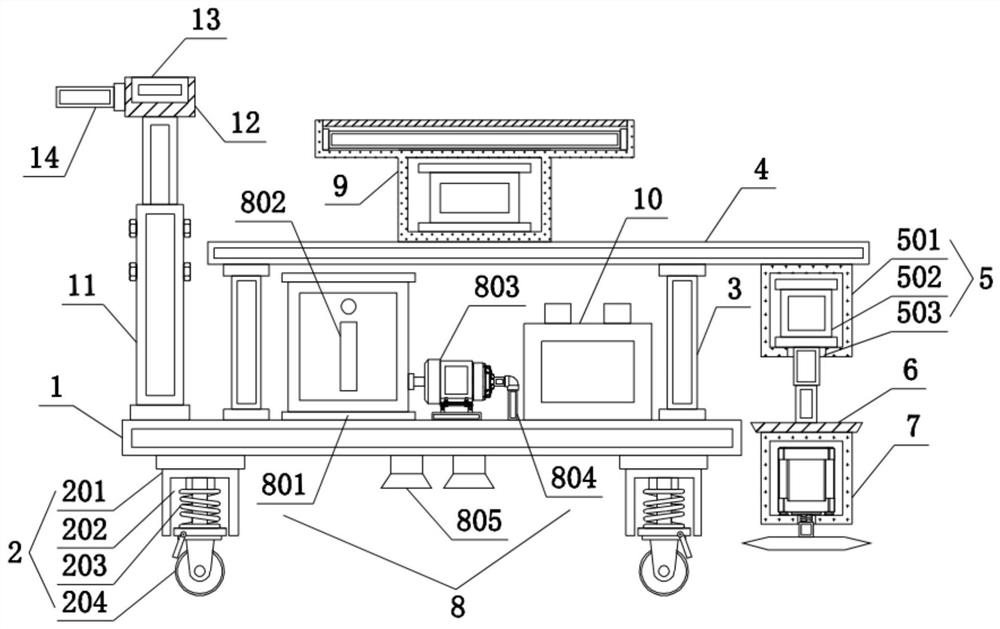

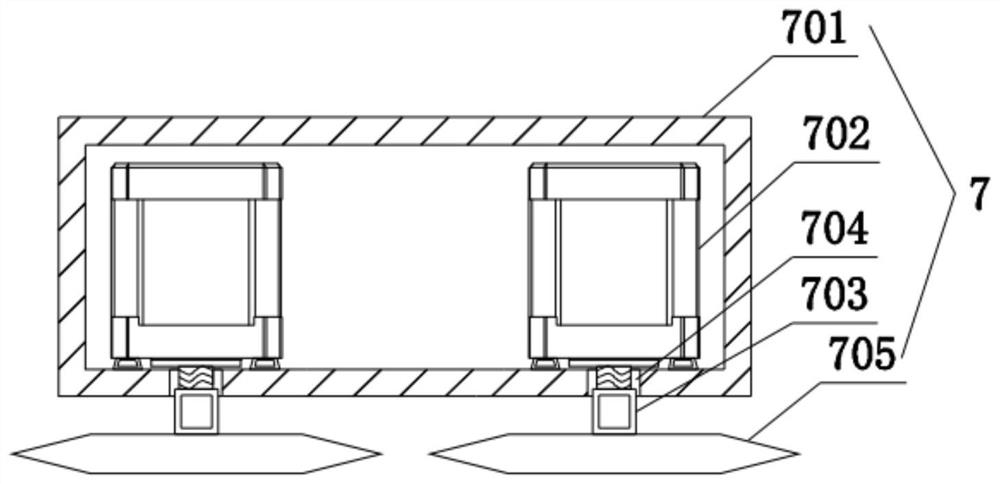

[0034] see Figure 1-5 , a portable weeder for sericulture tree maintenance, comprising a base plate 1, a moving mechanism 2 is fixedly installed on the bottom of the base plate 1, and a connecting column 3 is fixedly connected to the top four corners of the base plate 1, and the connecting column 3 tops are fixedly connected with a top plate 4, the right side of the bottom of the top plate 4 is fixedly equipped with a telescopic mechanism 5, the output end of the telescopic mechanism 5 is fixedly connected with a connecting plate 6, and the bottom of the connecting plate 6 is fixedly installed There is a mowing mechanism 7, a pesticide spraying mechanism 8 is fixedly installed on the top left side of the base plate 1, a solar power generation mechanism 9 is fixedly installed on the top of the top plate 4, and a storage battery 10 is fixedly installed on the top right side of the base plate 1, The top of the base plate 1 is fixedly connected with a telescopic rod 11 on the lef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com