800G optical module

A technology of optical modules and lasers, which is applied in the field of optical communications, can solve the problems of low reliability of packaging methods, increased wiring density, and low reliability, and achieve the effects of avoiding too compact arrangement, good heat dissipation performance, and reducing crosstalk problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

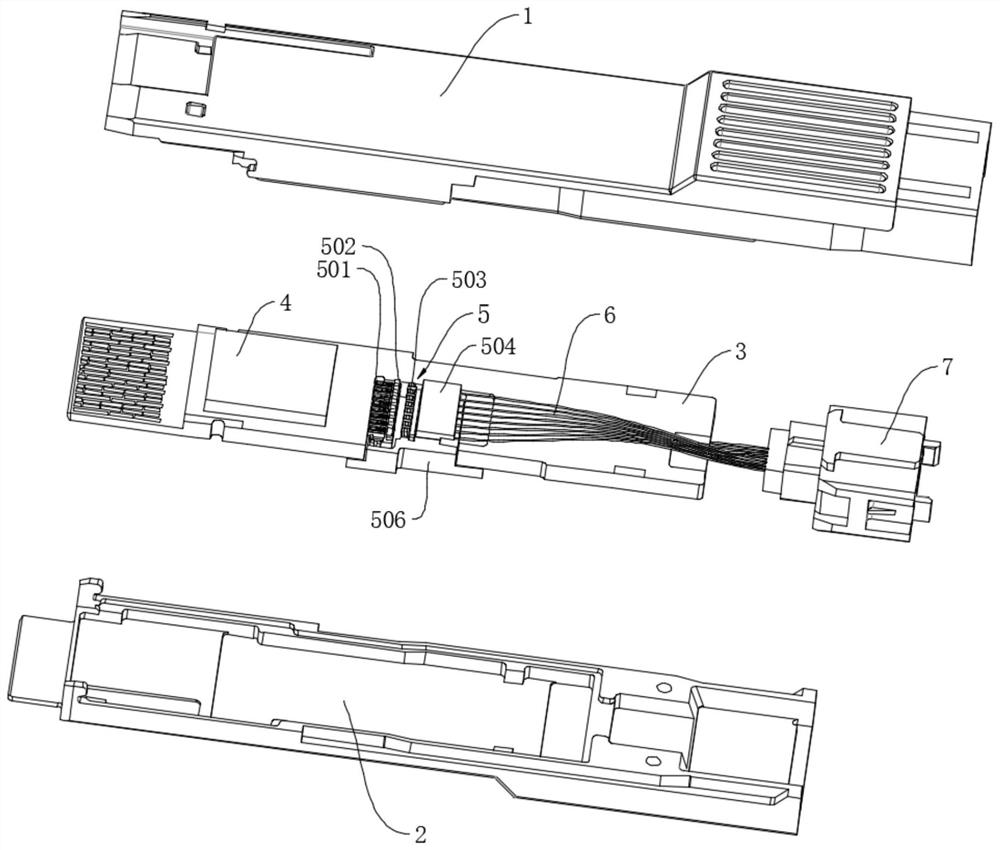

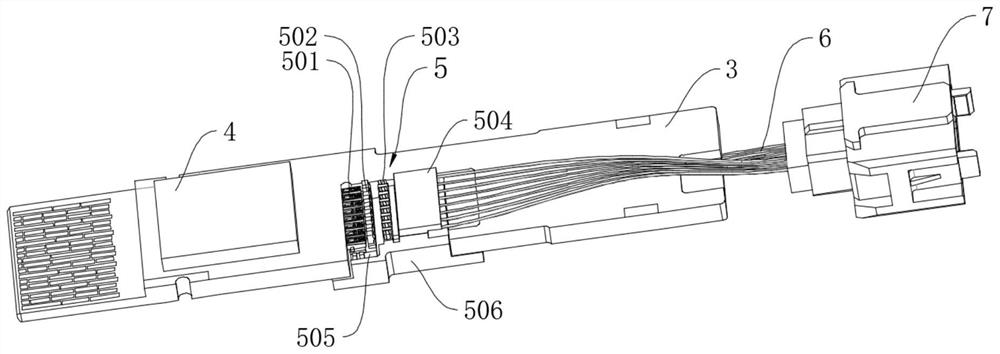

[0027] The technical solution of the present invention will be clearly and completely described below in conjunction with the accompanying drawings. The relevant components in the invention are not drawn according to the number, shape and size of the components in actual implementation. The type, quantity and proportion of each component in actual implementation can be changed arbitrarily, and the layout of the components may also be changed for complex.

[0028] The purpose of the present invention is to provide a packaging structure for 800G optical modules to address the shortcomings of the current optical module packaging structure, which not only ensures sufficient board space for optical module components and supporting circuits, but also ensures that optical chips The integrity of signal transmission and good heat dissipation performance, and the packaging structure is simple and reliable, and has good mass production feasibility.

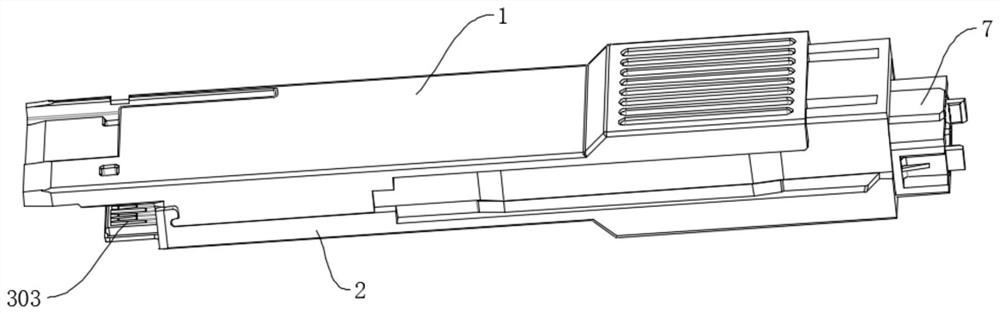

[0029] See Figure 1 to Figure 6 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com