Single-phase PuNi3 type superlattice La-Y-Ni series hydrogen storage alloy and preparation method thereof

A hydrogen storage alloy, la-y-ni technology, applied in the direction of chemical instruments and methods, hydrogen, non-metallic elements, etc., can solve the problem of reducing the contact density between powder materials, affecting the efficiency of solid phase diffusion reaction, and reducing the solid phase Diffusion uniformity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0054] Single-phase PuNi 3 The preparation method of type superlattice La-Y-Ni series hydrogen storage alloy specifically comprises the following steps:

[0055] Step 1: LaNi prepared by vacuum induction melting 5 、CeNi 5 、YNi 2 The alloy is crushed under the protection of the atmosphere, and the alloy powder below 38 microns is taken, according to LaNi 5 / CeNi 5 / YNi 2 The molar ratio is (1-x) / x / 2, 0≤x≤0.5, weigh and mix evenly;

[0056] Step 2: Put the mixed alloy powder into a graphite mold and put it into a vacuum hot pressing furnace, and hot press and form it into a hydrogen storage alloy material under vacuum conditions.

[0057] Step 21: Vacuumize the vacuum hot pressing furnace, the vacuum degree is ≤1.5×10 -2 Pa;

[0058] Step 22: Elevate from room temperature to holding temperature at a heating rate of 8-10°C / min, and press to form a hydrogen storage alloy material;

[0059] When the temperature rises from room temperature to 500°C, the pressure rises from ...

Embodiment 1

[0065] Embodiment 1: alloy composition is LaY 2 Ni 9

[0066] Will LaNi 5 and YNi 2 Separately crush with atmosphere protection, pass through a 38 micron sieve, keep the powder below 38 micron for later use, and return to continue crushing if it is above 38 micron; according to LaNi 5 / YNi 2 The molar ratio is 1 / 2, and the powder below 38 microns is weighed and mixed;

[0067] LaNi 5 / YNi 2 = 1 / 2 of the mixture was put into a graphite mold and placed in a vacuum autoclave; the vacuum was 1.5×10 -2 Pa; from room temperature to 930°C at a heating rate of 8°C / min, the holding temperature is 930°C, and the holding time is 6h; when rising from room temperature to 500°C, the pressure rises from no pressure to 35MPa, and the remaining temperature rises and The pressure of 35MPa is applied throughout the heat preservation stage; after the heat preservation is completed, it is cooled to room temperature with the furnace.

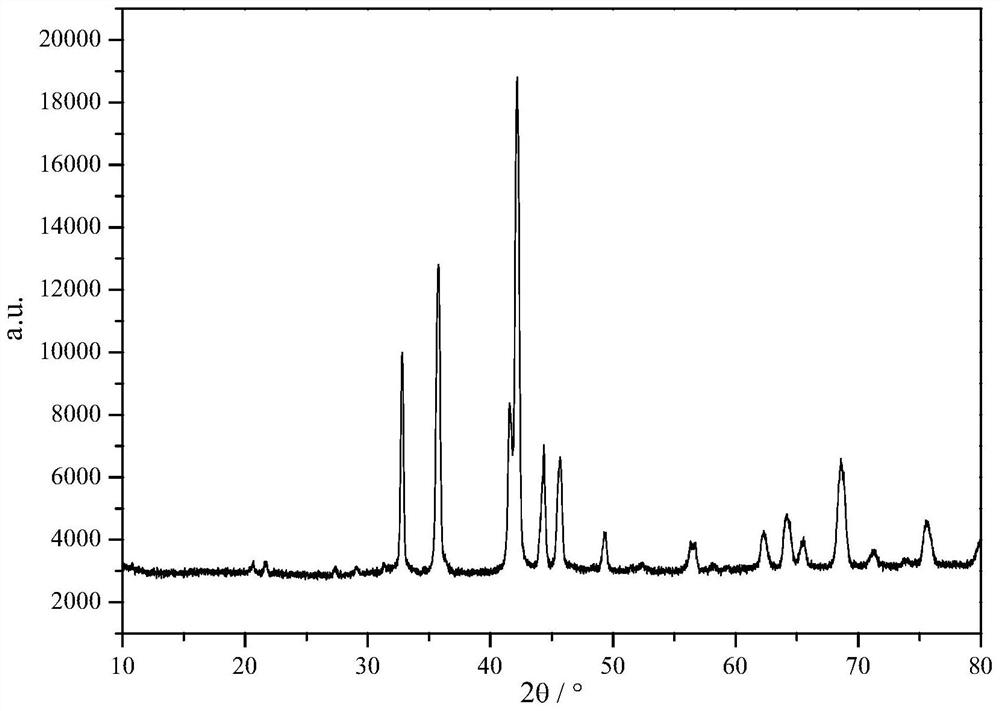

[0068] Such as figure 1 Shown, is the PuNi prepared i...

Embodiment 2

[0071] Embodiment 2: alloy composition is LaY 2 Ni 9

[0072] Will LaNi 5 and YNi 2 Separately crush with atmosphere protection, pass through a 38 micron sieve, keep the powder below 38 micron for later use, and return to continue crushing if it is above 38 micron; according to LaNi 5 / YNi 2 The molar ratio is 1 / 2, and the powder below 38 microns is weighed and mixed;

[0073] LaNi 5 / YNi 2 = 1 / 2 of the mixture was put into a graphite mold and placed in a vacuum autoclave; the vacuum was 1×10 -2 Pa, from room temperature to 950°C at a heating rate of 10°C / min, the holding temperature is 950°C, and the holding time is 6h; when the temperature rises from room temperature to 500°C, the pressure rises from no pressure to 20MPa, and the remaining temperature rises And the pressure of 20MPa is applied throughout the heat preservation stage; after the heat preservation is completed, it is cooled to room temperature with the furnace.

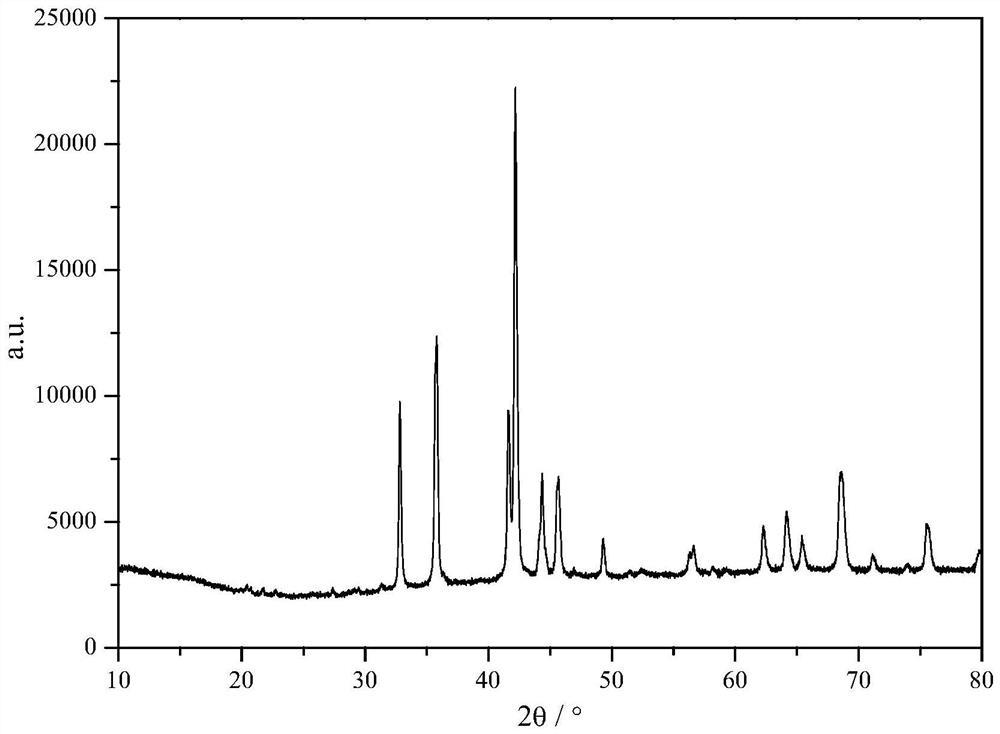

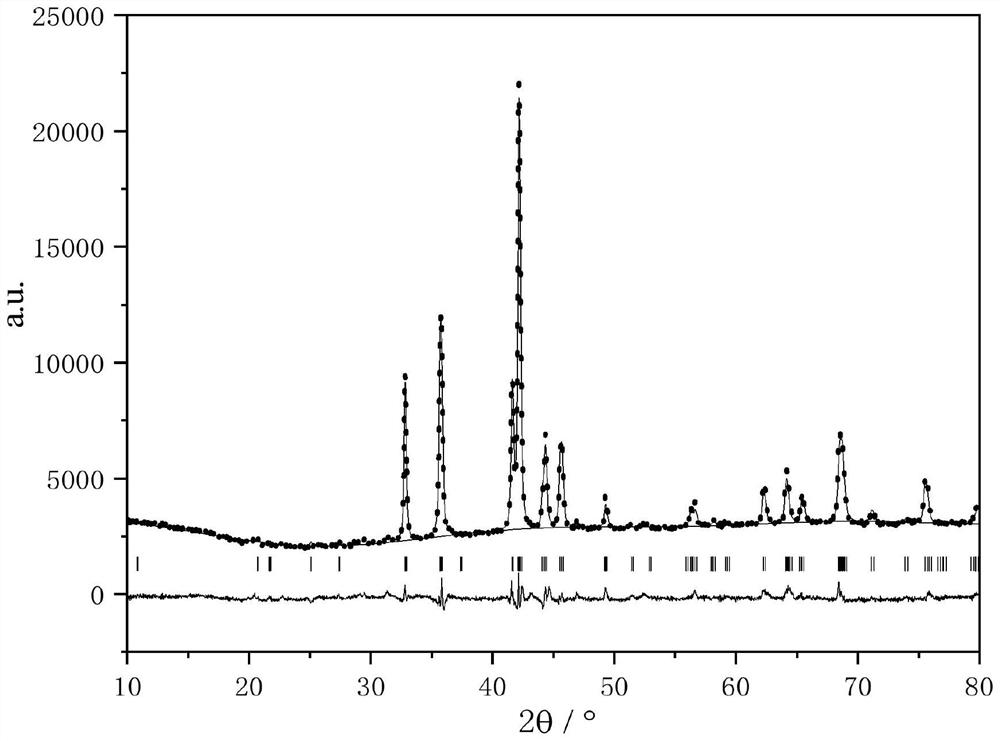

[0074] Such as figure 2 Shown is the X...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com