Propeller base of deepwater dynamic positioning crude oil conveying device and manufacturing method of propeller base

A technology for dynamic positioning and conveying devices, used in propulsion components, ship propulsion, transportation and packaging, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

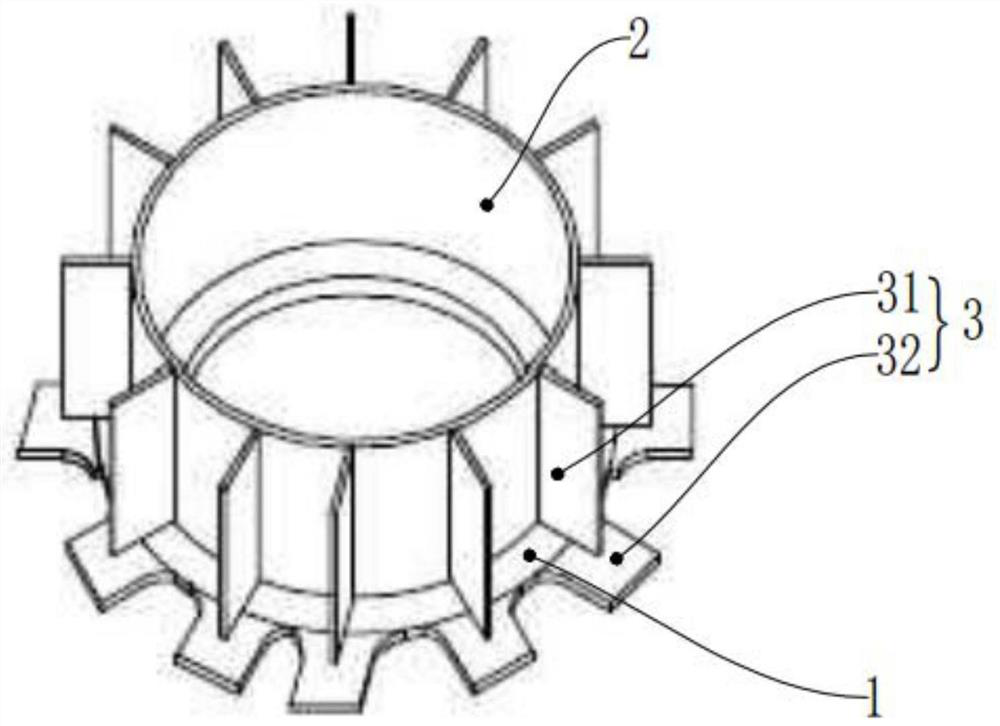

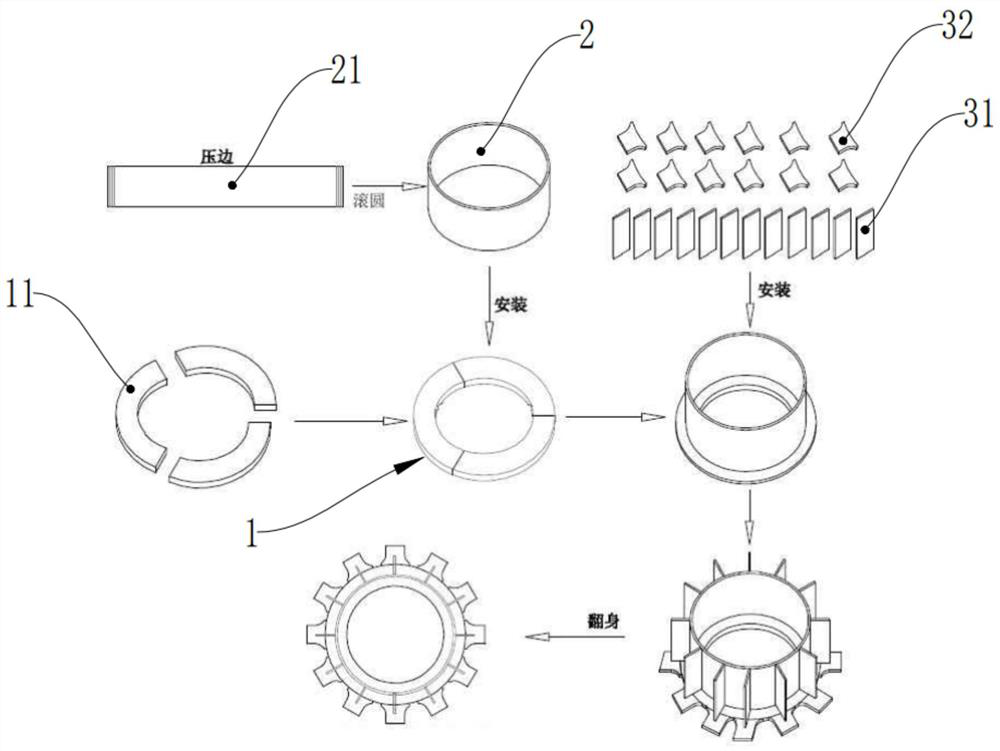

[0031] For the thruster base of the deep water dynamic positioning crude oil delivery device of this embodiment, refer to the attached figure 1 , including a flange 1, a cylinder 2 and a plurality of T-beams 3, the cylinder 2 is installed on the upper end of the flange 1, a plurality of T-beams 3 are evenly distributed on the outside of the cylinder, and the T-beams 3 It includes a web 31 and a panel 32, one side of the web 31 is connected to the outside of the cylinder, the bottom of the web 31 is connected to the upper side of the flange 1 and the panel 32, and one side of the panel 32 is connected to the side of the flange 1 External connection.

[0032] By setting the cylindrical body 2 and a plurality of T-shaped beams 3 on the flange 1, the assembled propeller base can provide a connection str...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com