Circumferential pull rod rotor experiment system

An experimental system, the technology of tie-rod rotors, applied in the testing of measuring devices, instruments, mechanical components, etc., can solve the problem of large differences in rotor structure, inability to conduct compressor disc and turbine disc integral rotor experiments, and inability to third-order Critical speed experimental measurement and other issues to achieve the effect of high experimental flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

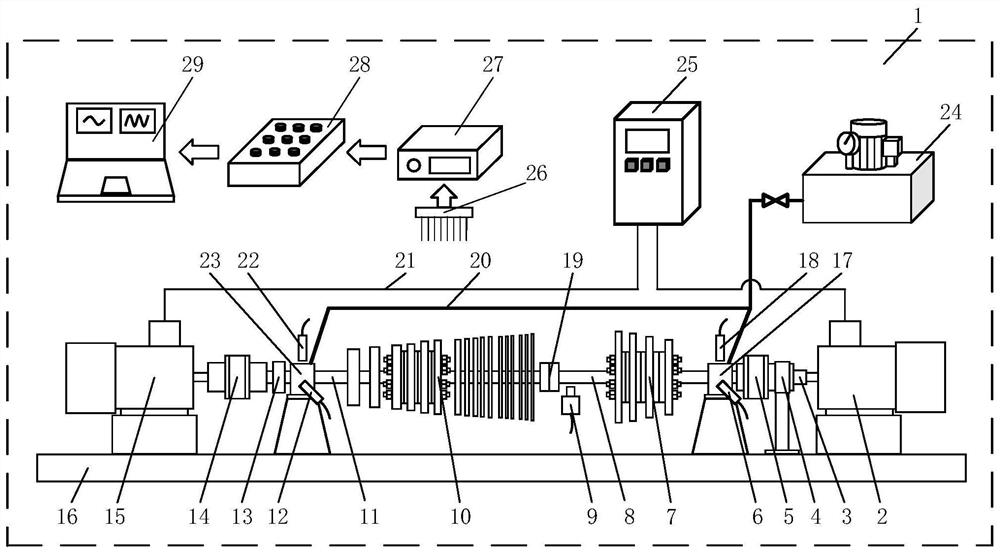

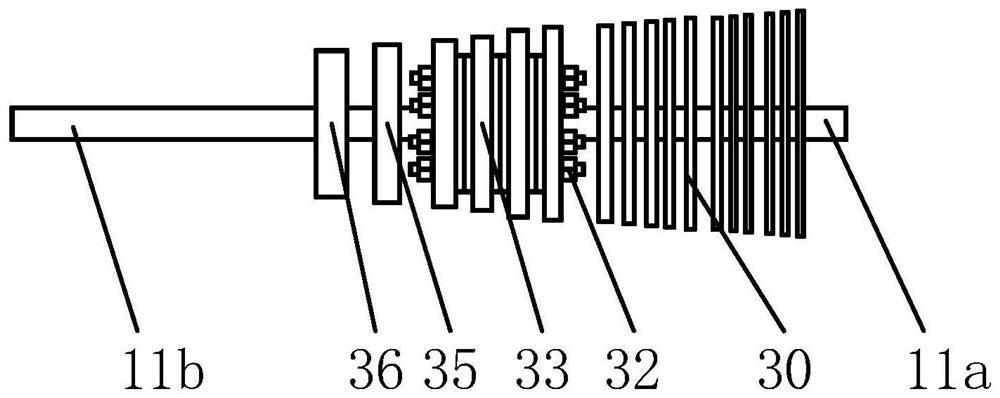

[0023] The overall structure, working principle and working process of the circumferential tie-rod rotor experimental system will be described in detail below in conjunction with the accompanying drawings.

[0024] figure 1 It is a schematic diagram of the overall structure of an embodiment of the circumferential tie rod rotor experimental system. The circumferential tie rod rotor experimental system 1 mainly includes a support base 16, a driving motor 2, an experimental rotor, a generator 15, a lubricating oil tank 24, a frequency converter 25 and data acquisition and Processing system: the experimental rotor includes an experimental rotor turbine shaft section 7 and an experimental rotor compressor shaft section 10; one end of the experimental rotor turbine shaft section passes through the first rolling bearing 17 and the first elastic coupling 5 in turn to drive The output shaft of the motor 2 is connected; one end of the experimental rotor compressor shaft section 10 is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com