Bridge construction pier supporting template

A formwork and pier technology, applied in the field of supporting and supporting formwork for bridge piers, can solve the problems of wasting resources, affecting the flushness of concrete surfaces, lack of protective measures, etc. Easy to install effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

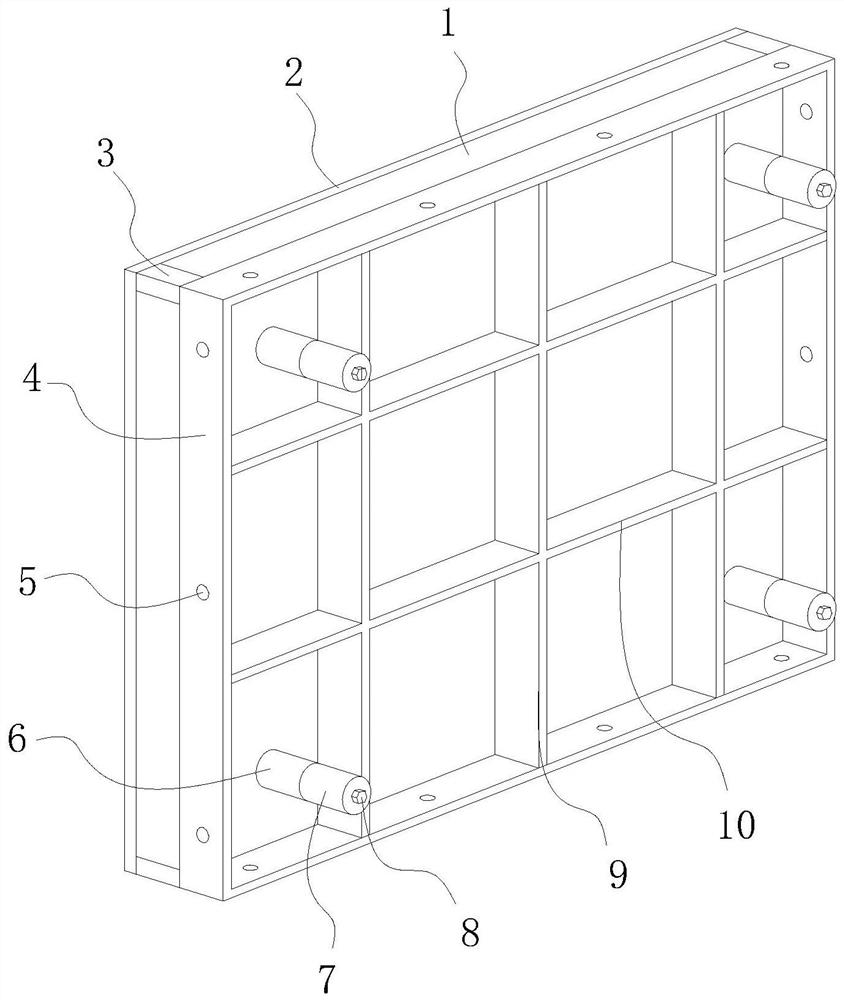

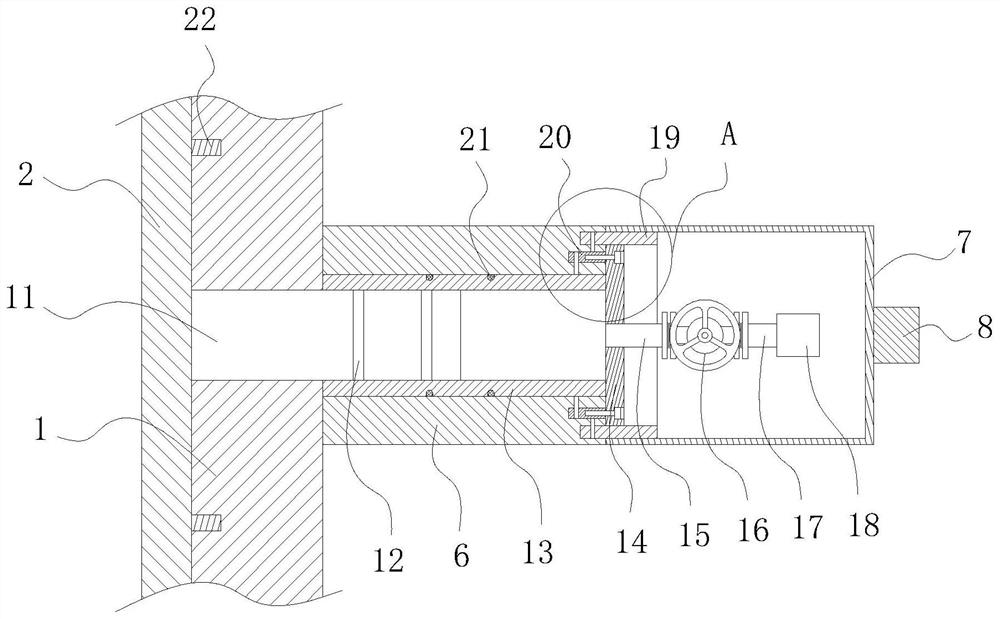

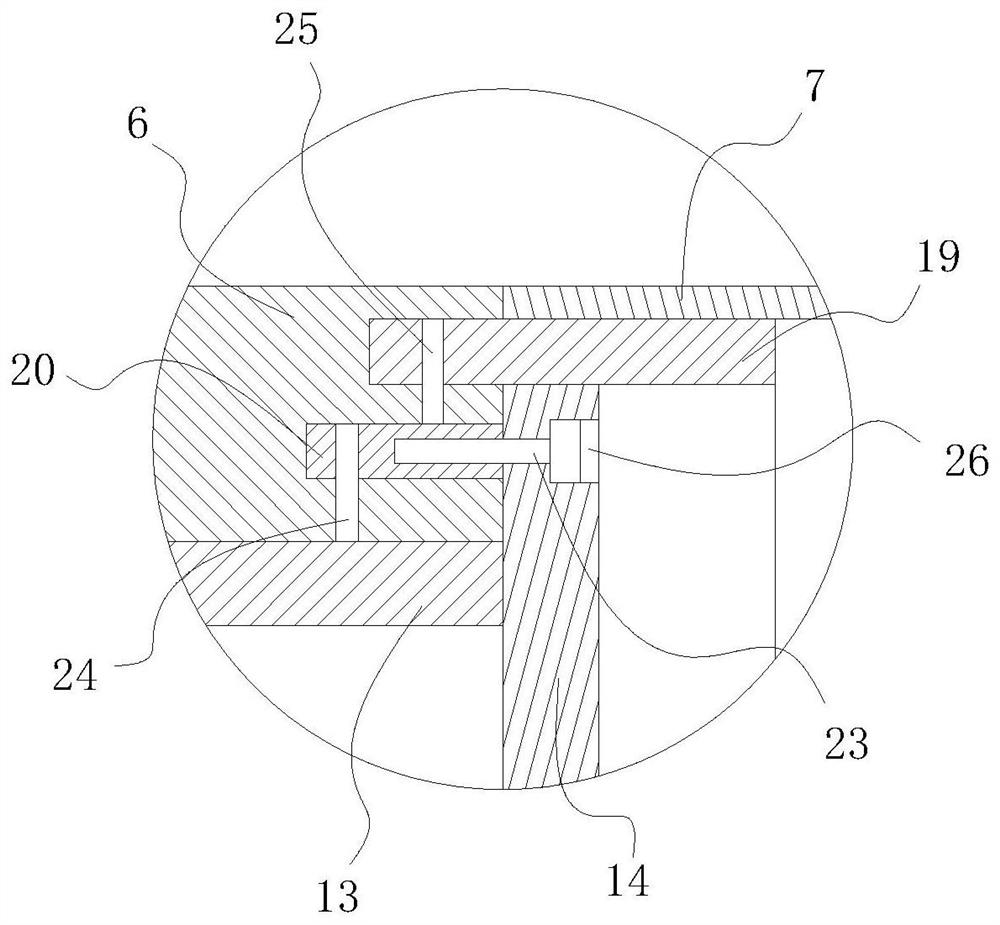

[0043] Specific implementation method: By installing a detachable protective plate 2 on the side of the formwork body 1 facing the concrete, and then under the blocking of the protective plate 2, the side of the formwork body 1 facing the concrete will be bumped to produce pits and other deformations, so as to protect the The function of the formwork body 1 can be replaced when the protective plate 2 is damaged. It is not necessary to discard the entire formwork body 1 to reduce the waste of resources. The cylinder 13 is inserted in the hollow column 6, and the disc body 14 is connected to the hollow column 6 by using the connecting screw 23. The column 6 is fixedly connected, and then the combined assembly of the cylinder 13 and the hollow column 6 is realized, that is, when the cylinder 13 matched with the cylindrical rod 11 is damaged, the cylinder 13 can be replaced to ensure that the cylinder 13 matched with the cylindrical rod 11 There are no scratches on the inner surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com