Anti-seismic connecting structure for fabricated steel-concrete composite beam

A steel-concrete composite beam and connection structure technology, which is applied to bridges, bridge parts, bridge construction, etc., can solve problems such as long cycle time, corrosion, and difficult quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

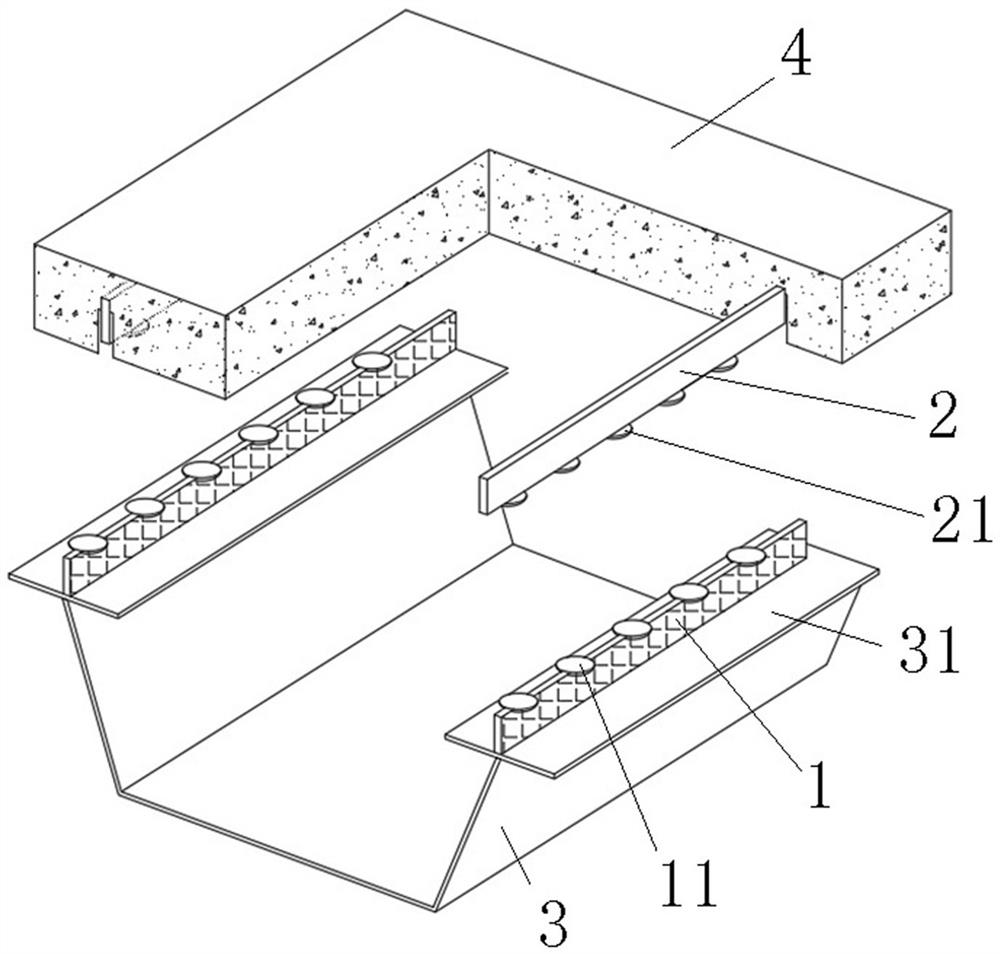

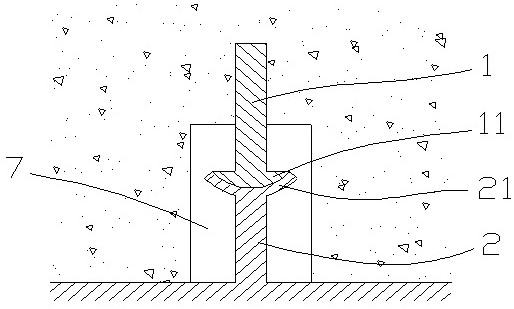

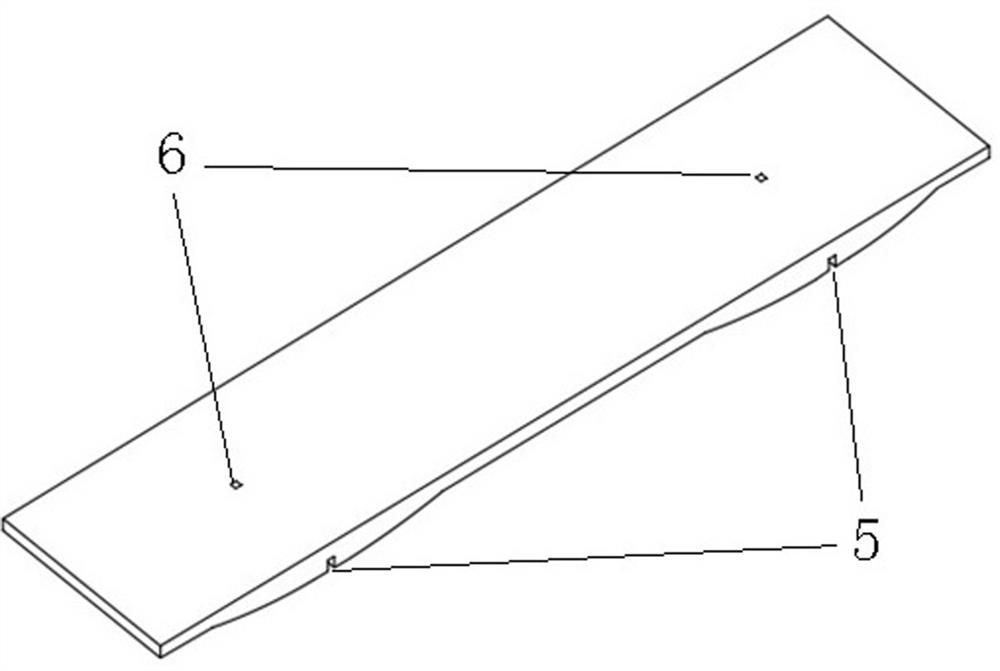

[0017] An anti-seismic coupling structure for prefabricated steel-concrete composite girders, including steel box girders and concrete bridge decks, both of which are prefabricated, and its innovation lies in: the two steel box girders Each flange plate is provided with a first connecting ridge 1, the axial direction of the first connecting ridge 1 is parallel to the axial direction of the flange plate, and the length of the first connecting ridge 1 is equal to the length of the flange plate; The upper end surface of the ridge 1 is provided with a plurality of semicircular grooves, and a female part 11 is arranged in each semicircular groove; The diameter is greater than the thickness of the first connecting ridge 1;

[0018] The lower side of the concrete bridge deck is provided with two grooves, the grooves are connected to the front and rear end faces of the concrete bridge deck; the axial direction of the groove is parallel to the axial direction of the concrete bridge dec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com