Biomass antibacterial plastic material and preparation method thereof

An antibacterial plastic and biomass technology, applied in the field of plastic materials, can solve the problems of no antibacterial function, affecting material processing fluidity, comprehensive performance and performance stability, and high additive content, achieving good comprehensive performance and performance stability, Outstanding antibacterial effect and excellent performance stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

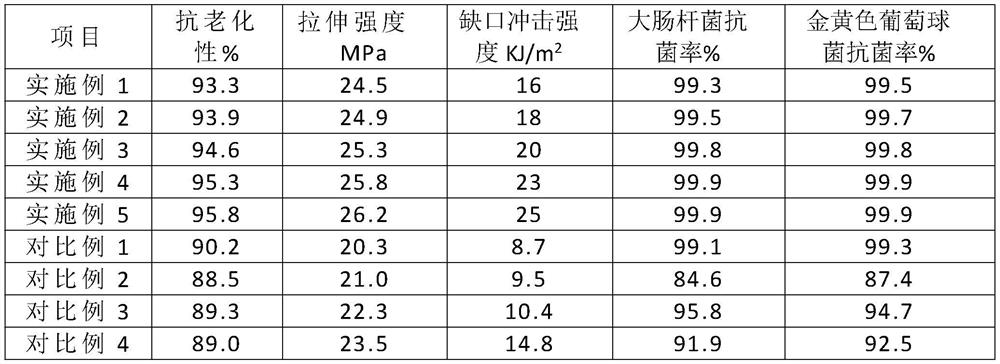

Examples

Embodiment 1

[0032] A kind of preparation method of biomass antibacterial plastic material is characterized in that, comprises the steps:

[0033] Step S1, preparation of 2,5-furandicarboxylic acid / polylactic acid polycondensate with double-terminated hydroxy groups: mix double-ended hydroxy-polylactic acid, 2,5-furandicarboxylic acid and catalyst evenly to obtain a mixed material, and then add the mixed material to In the high-pressure reaction kettle, replace the air in the kettle with inert gas, stir the esterification reaction at a temperature of 180°C and a pressure of 50KPa for 1 hour, then raise the temperature to 220°C, adjust the reaction pressure to 20kPa, and the reaction time is 1 hour ; then the reaction pressure is 50Pa, the temperature is 230 ℃, the reaction time is 8h, after the reaction is completed, cool to room temperature, adjust the pressure to normal pressure, discharge, and the obtained crude product is precipitated in water, and then the precipitated The polycondens...

Embodiment 2

[0042] A kind of preparation method of biomass antibacterial plastic material is characterized in that, comprises the steps:

[0043] Step S1, preparation of 2,5-furandicarboxylic acid / polylactic acid polycondensate with double-terminated hydroxy groups: mix double-ended hydroxy-polylactic acid, 2,5-furandicarboxylic acid and catalyst evenly to obtain a mixed material, and then add the mixed material to In the high-pressure reaction kettle, replace the air in the kettle with inert gas, stir the esterification reaction at a temperature of 185°C and a pressure of 60KPa for 1.5 hours, then raise the temperature to 225°C, adjust the reaction pressure to 23kPa, and the reaction time is 1.2 hours ; then the reaction pressure is 60Pa, the temperature is 233 ℃, the reaction time is 9h, after the reaction is completed, cool to room temperature, adjust the pressure to normal pressure, discharge, and the obtained crude product is precipitated in water, and then the precipitated The polyc...

Embodiment 3

[0052] A kind of preparation method of biomass antibacterial plastic material is characterized in that, comprises the steps:

[0053] Step S1, preparation of 2,5-furandicarboxylic acid / polylactic acid polycondensate with double-terminated hydroxy groups: mix double-ended hydroxy-polylactic acid, 2,5-furandicarboxylic acid and catalyst evenly to obtain a mixed material, and then add the mixed material to In the high-pressure reaction kettle, replace the air in the kettle with inert gas, stir the esterification reaction at a temperature of 190°C and a pressure of 75KPa for 2 hours, then raise the temperature to 230°C, adjust the reaction pressure to 30kPa, and the reaction time is 1.5 hours ; then the reaction pressure is 65Pa, the reaction time is 10h at a temperature of 235°C, after the reaction is completed, cool to room temperature, adjust the pressure to normal pressure, discharge, and the obtained crude product is precipitated in water, and then the precipitated The polyco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com