Self-repairing polyurethane based on two-way repairing structure, preparation method and application thereof

A technology for repairing structure and polyurethane, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems such as no self-healing polyurethane material reports, loss of use efficiency, cracking, etc., and achieve the effect of excellent repair rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0084]Preparation Example 1: Preparation of Solid Product A1 and Solid Product A2

[0085] At 40° C., 1.1 mol of p-hydroxybenzaldehyde in isopropanol (300 mL) was added into 0.5 mol of oxalodihydrazide in glacial acetic acid (250 mL), and stirred at 300 rpm for 4 h. After the reaction, filter under reduced pressure, wash with ethanol three times at 50° C., then wash with water three times, and dry the washed product to obtain solid product A1.

[0086] At 60° C., 0.2 mol of furfurylamine was added into a solution of resorcinol diglycidyl ether (0.1 mol) dissolved in methanol (50 mL), and reacted for 6 h under stirring at 500 rpm. After the reaction, the product was distilled under reduced pressure, washed with secondary water, and dried to obtain the solid product A2.

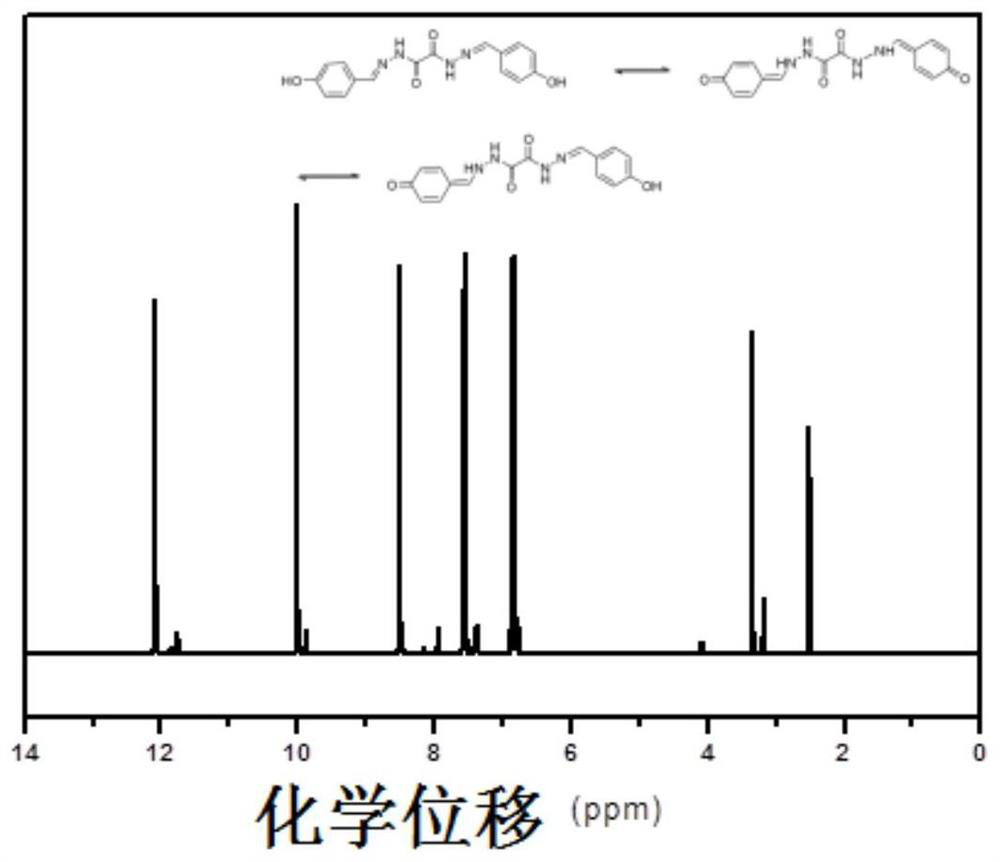

[0087] And, the proton nuclear magnetic spectra of solid product A1 and solid product A2 are respectively as follows figure 1 and figure 2 shown.

Embodiment 1

[0088] Embodiment 1: prepare polyurethane

[0089] At 50°C, 0.1 mol of isophorone diisocyanate was slowly added to the molecular weight M dissolved in N,N-dimethylformamide (300 mL) n In the polyethylene glycol (PEG 600, 0.05mol) of =600, add the dibutyltin dilaurate of 500ppm (based on the total weight of isophorone diisocyanate and polyethylene glycol), react 3h under rapid stirring, Obtain polyurethane prepolymer pre-600.

[0090] At 50°C, dissolve 0.22mol of polyurethane prepolymer pre-600 and 0.1mol of mixture A (0.05mol of solid product A1 in Preparation 1 and 0.05mol of N,N-dimethylformamide (200mL in total)) The solid product A2) in Preparation Example 1 was mixed and reacted for 12 h under stirring at 200 rpm to obtain linear polyurethane 1-600.

[0091] Add 0.06 mol of N,N'-(4,4'-methylenediphenyl)bismaleimide to linear polyurethane 1-600 (the entire amount obtained in the previous step) at 55 °C N,N-dimethylformamide dispersion liquid, mixed and stirred evenly, t...

Embodiment 2

[0092] Embodiment 2: prepare polyurethane

[0093] At 35°C, 0.1 mol of isophorone diisocyanate was slowly added to the molecular weight M dissolved in N,N-dimethylformamide (300 mL) n In the polyethylene glycol (PEG 1000, 0.05mol) of =1000, add the dibutyltin dilaurate of 500ppm (based on the total weight of isophorone diisocyanate and polyethylene glycol), react 4h under rapid stirring, The polyurethane prepolymer pre-1000 was obtained.

[0094] At 40°C, 0.22mol of polyurethane prepolymer pre-1000 and 0.1mol were dissolved in dimethyl sulfoxide (200mL in total) in mixture A (0.05mol of solid product A1 in Preparation 1 and 0.05mol of Preparation 1 The solid product A2) was mixed and reacted for 20h under stirring at 200rpm to obtain linear polyurethane 1-1000.

[0095] Add 0.06 mol of N,N'-(4,4'-methylenediphenyl)bismaleimide to linear polyurethane 1-1000 (the entire amount obtained in the previous step) at 60 °C N,N-dimethylformamide dispersion liquid, mixed and stirred e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com