Lens cleaning and drying device

A drying device and cleaning technology, applied in the direction of using liquid cleaning methods, drying, dryers, etc., can solve the problems of inability to achieve lens drying, inconvenient cleaning agent collection, etc., to prevent splashing and moving around precise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

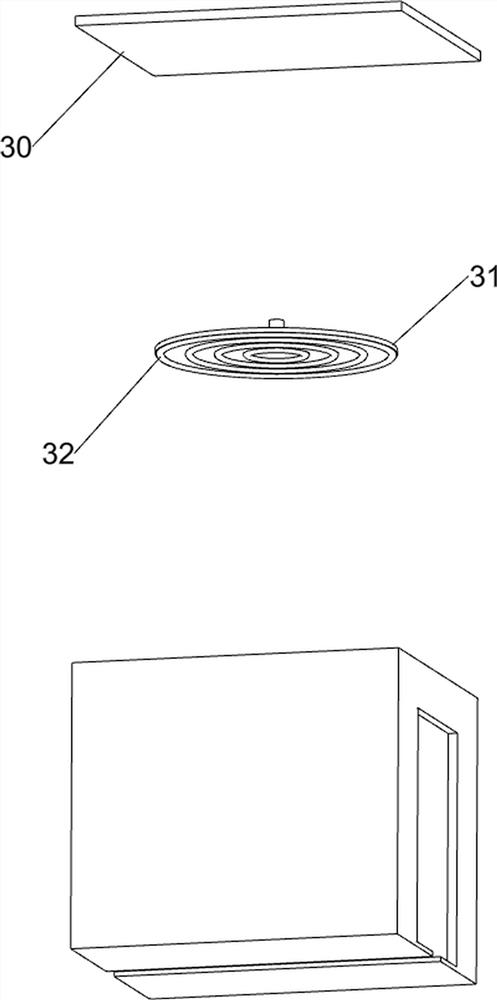

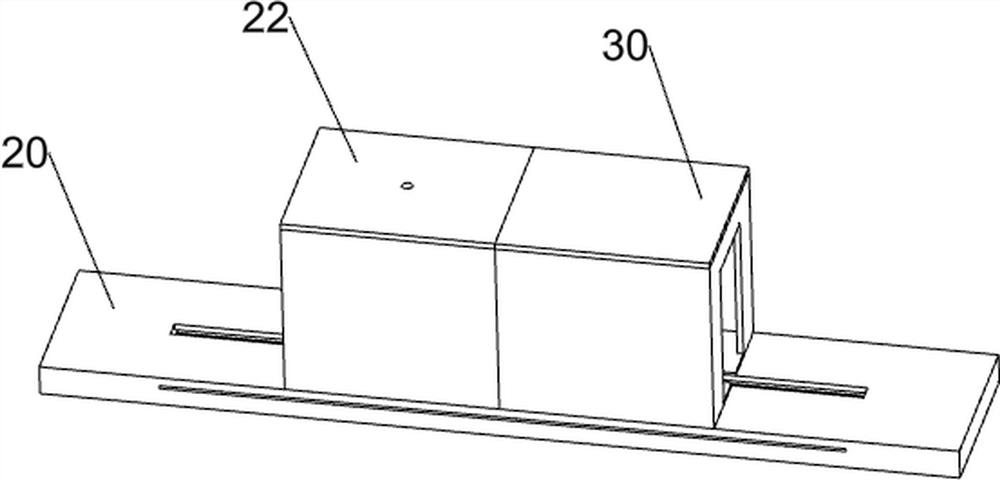

[0030] A device for lens cleaning and drying, such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 6 As shown, it includes a base 1 , a cleaning mechanism 2 and a drying mechanism 3 , the base 1 is provided with a cleaning mechanism 2 , and the cleaning mechanism 2 is provided with a drying mechanism 3 .

[0031] When people need to use this device, first people will evenly place the lens on the cleaning mechanism 2 charging parts, then people can clean the lens with cleaning agent, and start the drying mechanism 3, and when the washing is completed, people will clean the lens 2 The charging part moves to the right, and the cleaning mechanism 2 charging part drives the lens to move to the right. At the same time, people move the other part of the cleaning mechanism 2 backward. When the cleaning mechanism 2 charging part drives the lens to move to the drying mechanism 3, Stop moving the cleaning mechanism 2 loading parts, so that the drying mechanism 3 dries the ...

Embodiment 2

[0036] On the basis of Example 1, such as figure 1 , Figure 5 , Figure 6 , Figure 7 , Figure 8 and Figure 9 Shown, also comprise flushing mechanism 4, and flushing mechanism 4 comprises connecting plate 40, servomotor 41, the first spur gear 42, water pipe 43, the second spur gear 44 and sprinkler 45, and cleaning box 22 is provided with connecting plate 40 , the connecting plate 40 is provided with a servo motor 41, the output shaft of the servo motor 41 is provided with a first straight gear 42, the cleaning box 22 is connected with a water pipe 43 in a rotational manner, the water pipe 43 is provided with a second straight gear 44, and the second straight gear The gear 44 meshes with the first spur gear 42, and the lower part of the water pipe 43 is provided with a sprinkler 45.

[0037] At first people connect water pipe 43 with the container that cleaning agent is housed, and start servomotor 41, then when eyeglass moves to below sprinkler 45, people reset slide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com