Ni-Fe-BASED ALLOY POWDER, AND METHOD FOR PRODUCING ALLOY FILM USING SAID Ni-Fe-BASED ALLOY POWDER

A manufacturing method and technology of base alloy, applied in the direction of metal material coating process, coating, melt spraying, etc., can solve the problem of insufficient corrosion resistance, and achieve the effect of prolonging the life, reducing the thermal impact, and reducing the cost of materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

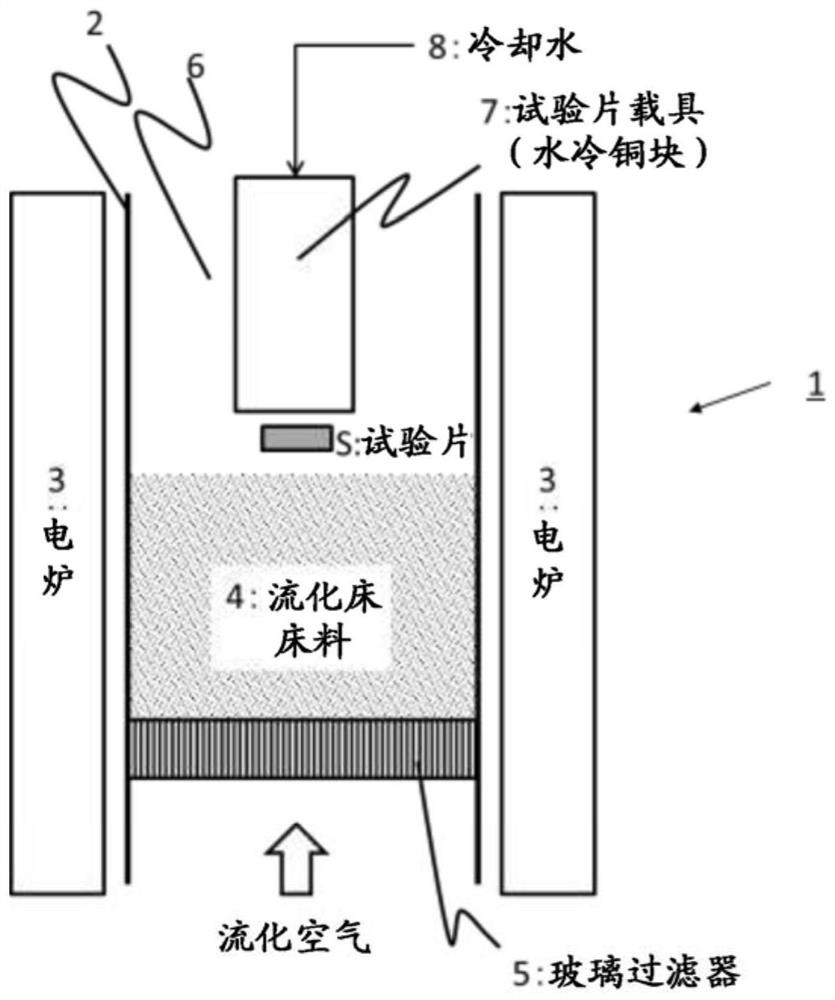

[0071] use figure 1 Shown is a small-scale fluidized bed test setup to evaluate the corrosion and wear characteristics of Ni-Fe-based alloy powders. The fluidized bed test apparatus 1 is equipped with the container 2 which forms the fluidized bed 4 which consists of bed materials, and the electric furnace 3 provided in the outer periphery of the container 2. At the bottom of the vessel 2, the bed material is kept and a glass filter 5 is provided for supplying fluidizing air. A test piece carrier (water-cooled copper block) 7 for holding the test piece S inside or above the fluidized bed 4 is provided on the test section 6 at the upper part of the container 2 . A cooling water conduit 8 for supplying cooling water is connected to the test piece carrier 7 .

[0072] The test piece S was installed on the test piece carrier 7 of the fluidized bed tester 1, and the atmosphere gas and the bed material in the container 2 were kept at 700° C. The cooling water in tool 7 is used for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com