Beam-column structure for anti-seismic support of fabricated building

A beam-column structure and prefabricated technology, which is applied to building components, building structures, protective buildings/shelters, etc., can solve problems such as strong collisions, weak earthquake resistance, and low integration, and improve structural stability High performance, small pouring volume, and avoiding mutual impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

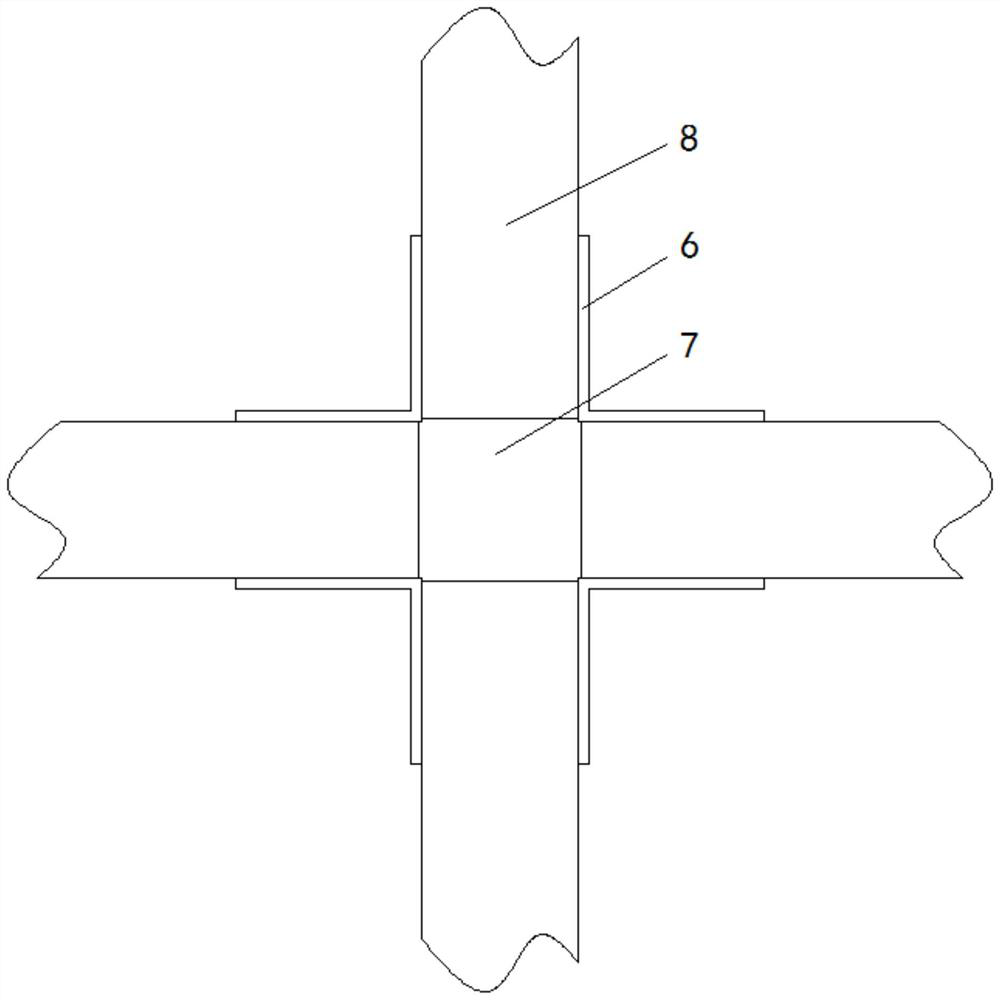

[0021] see Figure 1~3 , in an embodiment of the present invention, a beam-column structure used for the seismic support of a prefabricated building includes a load-bearing column 1, a steel frame 2 is fixedly installed inside the load-bearing column 1, and a relief groove 3 is opened on the top of the load-bearing column 1, The inside of the load-bearing column 1 is fixedly installed with a quantity of four and extends to the first steel bar 4 inside the give way groove 3, and the bottom of the inner wall of the make way groove 3 is fixedly installed with a fixed seat 10, and the left and right sides of the fixed seat 10 are fixed. There are four fixed legs 11 welded to the four first reinforcement bars 4 respectively, the tops of the four fixed legs 11 are fixedly equipped with vibration-isolation springs 12, and the tops of the four vibration-isolation springs 12 are fixedly installed with connection Plate 5, the bottom of the connecting plate 5 is fixedly installed with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com