A kind of preparation method and application of supercritical carbon dioxide thickener

A carbon dioxide and supercritical technology, applied in the direction of chemical instruments and methods, drilling compositions, bulk chemical production, etc. High price of fluorine-based substances and other problems, to achieve excellent thickening effect, thickening supercritical carbon dioxide, and excellent thickening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

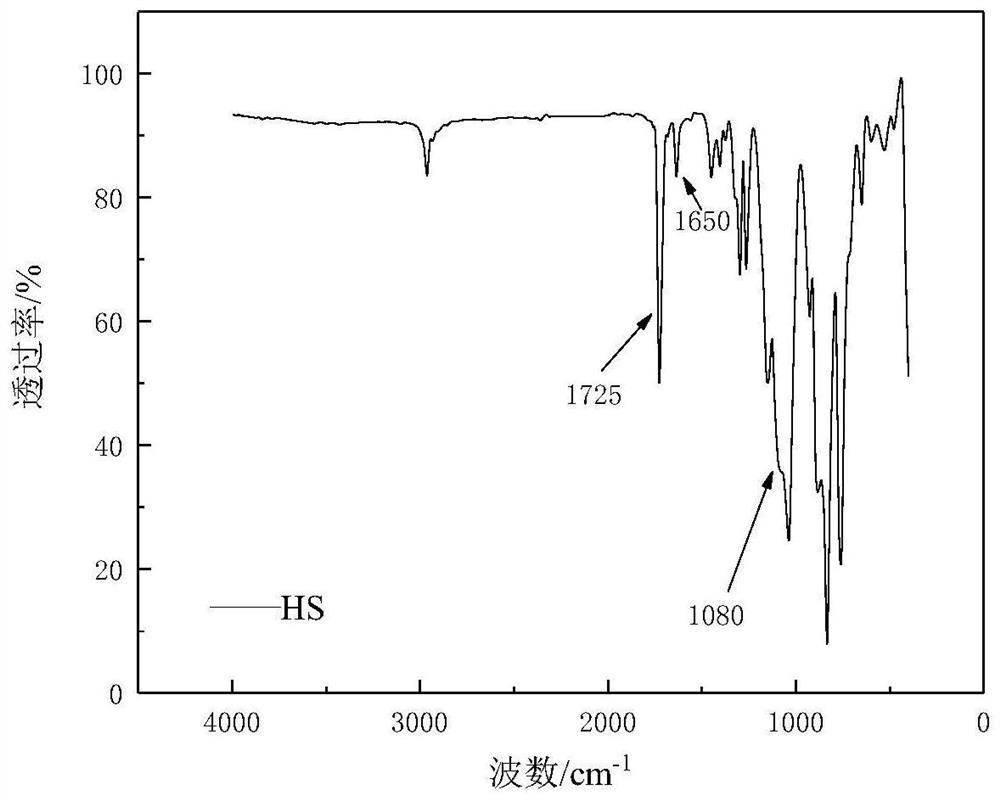

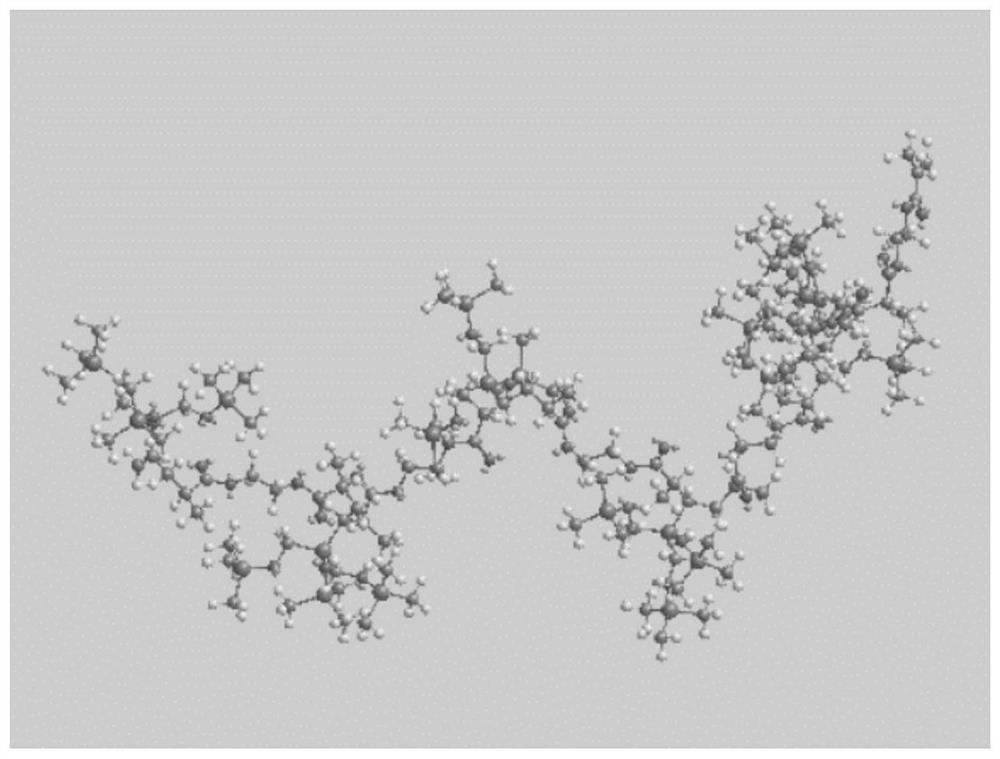

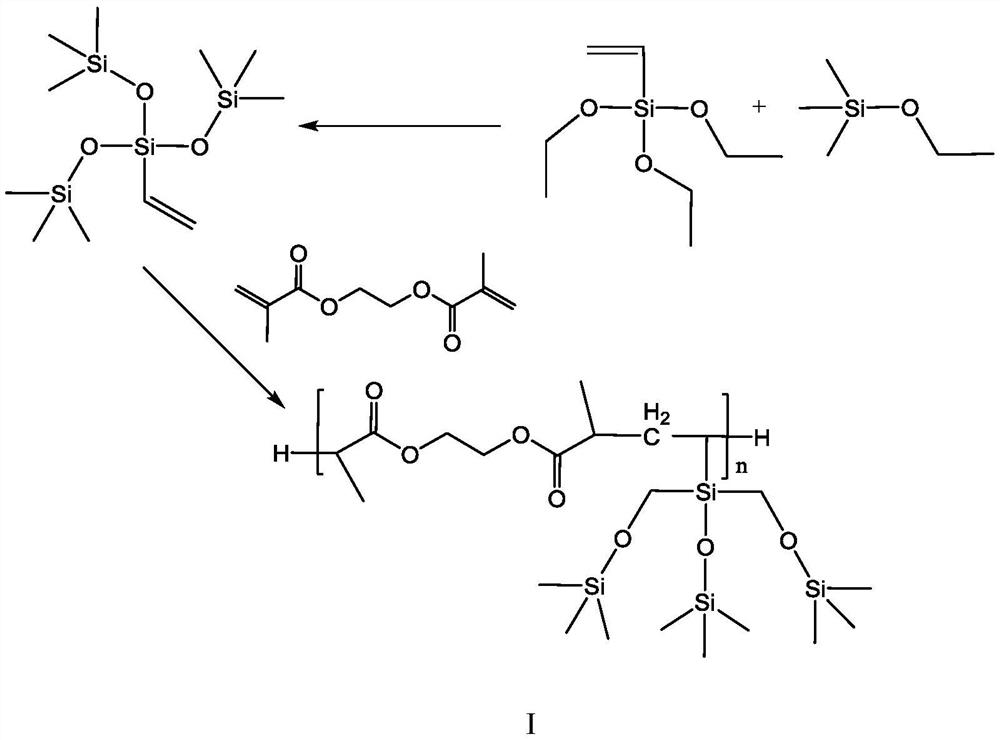

[0060] Embodiment 1, a kind of preparation method of acrylate / siloxane supercritical carbon dioxide thickener comprises steps as follows:

[0061] (1) Place the three-neck flask in a constant temperature magnetic stirring oil bath, add 9.3203g of ethoxytrimethylsilane and 5g of vinyltriethoxysilane in sequence, stir and heat to 60°C, and drop an appropriate amount of hydrochloric acid to make the reaction System pH=3, condensed and refluxed, reacted for 2.5h. After the hydrolysis and condensation reaction is completed, low-boiling impurities such as ethanol, water and ungrafted raw materials produced in the hydrolysis process are removed by rotary evaporation. The crude product was washed successively with sodium bicarbonate and deionized water, and dried to obtain a branched chain silane, ie, vinyl tris(trimethylsiloxane) silane. for step (2).

[0062] (2) Add 8.1399g vinyl tris(trimethylsiloxane) silane and 5g ethylene glycol dimethacrylate in the reactor equipped with ref...

Embodiment 2

[0064] Example 2, as described in Example 1, the operation steps are the same, except that the reaction temperature in step (1) is 70°C.

Embodiment 3

[0065] Embodiment 3, as described in Embodiment 1, the difference is that the ethoxytrimethylsilane in step (1) is 6.3216g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com