Roller composite ceramic repairing, regenerating and life-prolonging method

A composite ceramic, repair and regeneration technology, applied in the field of conveying machinery, can solve the problems of the wear-resistant ceramic rubber plate and the metal drum detached, not resistant to moisture, affecting the normal operation of the drum, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

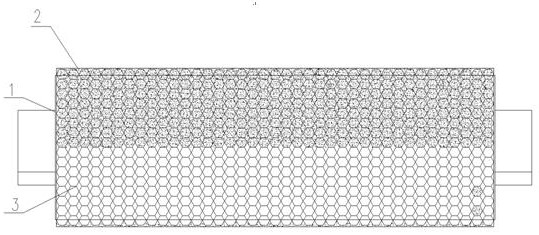

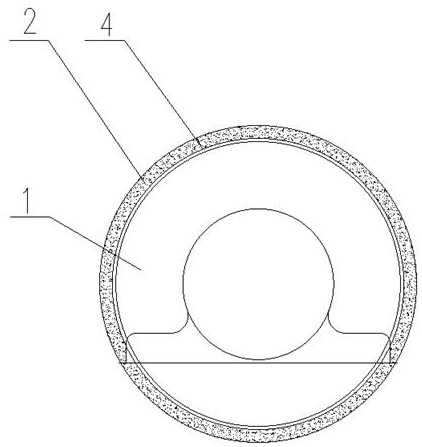

[0033] figure 1 , 2 As shown, a drum composite ceramic repair regeneration and life extension method includes a drum 1, the surface of the drum 1 is composited with a ceramic layer 2, and a tortoise shell net 3 or an anchor nail 4 is welded between the ceramic layer and the drum;

[0034] Specific steps are as follows:

[0035] The first step: clean the outer surface of the drum;

[0036] Step 2: Weld ceramic anchors or tortoise shell nets on the outer surface of the drum;

[0037] Step 3: Stick a layer of viscous ceramic material masterbatch on the outer surface of the drum, and adjust the dimensional accuracy of the cylindrical surface;

[0038] The fourth step: bake and solidify the ceramic masterbatch;

[0039] Step 5: Use a 3000°C high-temperature flame to rapidly heat and fire along the surface of the cured ceramic masterbatch, so that the temperature from the surface of the ceramic masterbatch to a depth of 5mm reaches 2030°C, and the surface of the ceramic masterba...

Embodiment 2

[0043] figure 1 As shown, a drum composite ceramic repair regeneration and life extension method includes a drum 1, the surface of the drum 1 is composited with a ceramic layer 2, and a tortoise shell net 3 is welded between the ceramic layer and the drum;

[0044] Specific steps are as follows:

[0045] The first step: clean the outer surface of the drum;

[0046] Step 2: Weld ceramic anchors or tortoise shell nets on the outer surface of the drum;

[0047] Step 3: Stick a layer of viscous ceramic material masterbatch on the outer surface of the drum, and adjust the dimensional accuracy of the cylindrical surface;

[0048] Step 4: Baking and curing ceramic masterbatch;

[0049] Step 5: Use a high-temperature flame to rapidly heat and fire along the surface of the solidified ceramic masterbatch, so that the surface of the ceramic masterbatch reaches 2080°C within a depth of 5mm, keep it for 15-20 seconds, and then cool naturally to room temperature.

[0050] Described cera...

Embodiment 3

[0055] It differs from Embodiment 1 in that anchor nails 4 are welded between the ceramic layer and the drum. The thickness of the composite ceramic layer is 20 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com