Drum-type workpiece polishing system and polishing method

A drum type and workpiece technology, which is applied in the field of drum type workpiece finishing system, can solve the problems of increasing equipment cost and occupying space, and achieve the effect of improving the finishing effect, reducing equipment cost and good finishing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

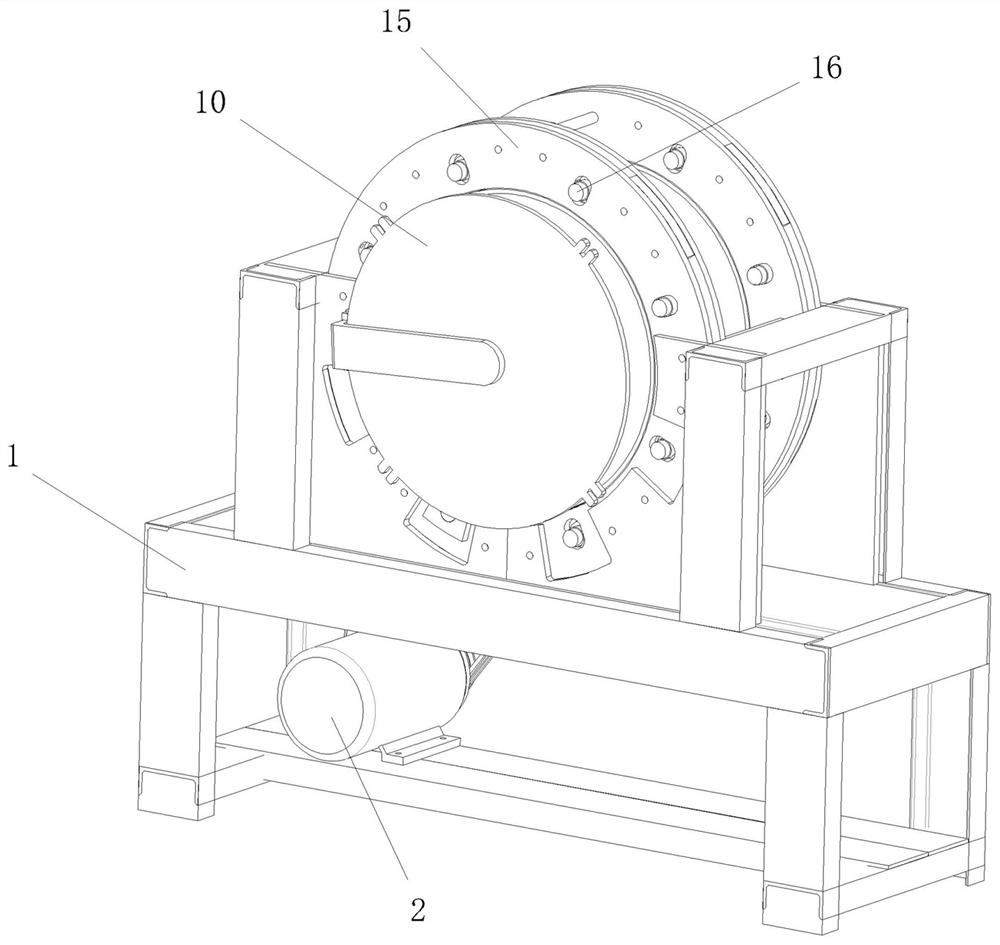

[0029] See attached figure 1 with 2 , the present invention provides a drum-type workpiece finishing system, including a frame 1, a workpiece finishing machine A arranged on the frame 1 for finishing workpieces, and a polishing machine A for transporting abrasive materials discharged after finishing Abrasive conveyor B.

[0030] Abrasive conveyor B is a belt conveyor, located below workpiece finishing machine A, and baffles are respectively arranged on both sides of its conveying direction to facilitate the collection of abrasives.

[0031] See attached Figure 3-7 The above-mentioned workpiece finishing machine A includes a drum assembly, a motor 2 for driving the drum assembly to rotate, an inner cylinder 3 disposed in the drum assembly for forming a grinding chamber, and a workpiece accommodating assembly disposed in the grinding chamber. During the finishing process, the workpiece to be ground is placed in the workpiece accommodating assembly, and the grinding of the wo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com