Vacuum-ultrasonic composite brazing device and method

An ultrasonic brazing and vacuum technology, used in welding equipment, metal processing, metal processing equipment, etc., can solve the problem of inability to balance welding quality and efficiency, achieve high degree of automation, reduce thermal damage, and prevent oxidation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

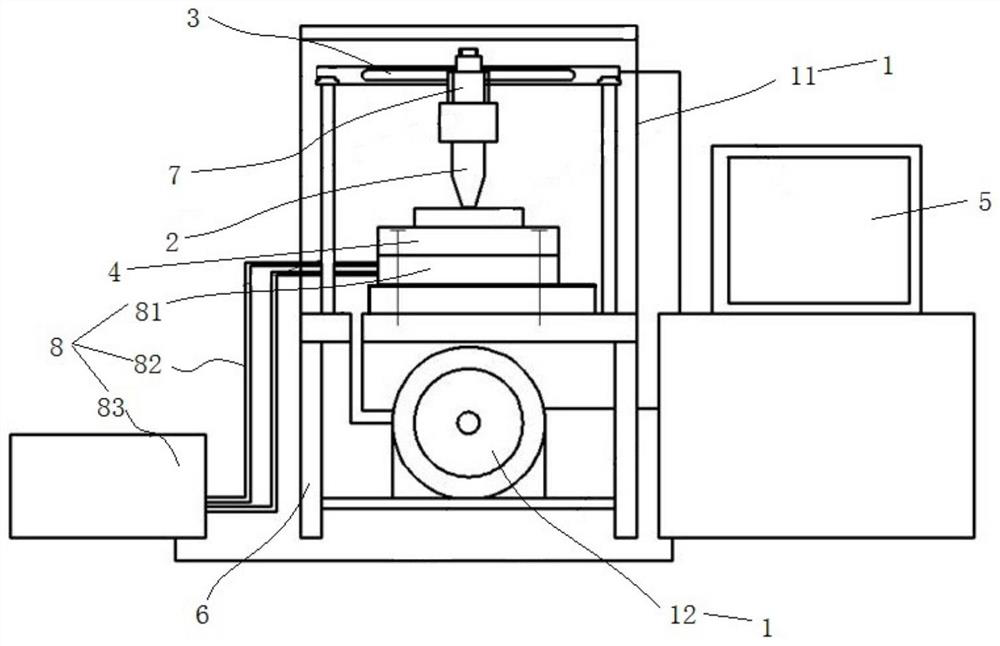

[0039] Such as figure 1 As shown, a vacuum-ultrasonic composite brazing device includes a vacuum assembly 1, an ultrasonic brazing assembly 2, a CNC motion assembly 3, a heating assembly 4, and a controller 5. The vacuum assembly 1 includes a vacuum cover 11, and the vacuum cover 11 A space for processing is formed. For the convenience of taking the weldment, a hatch can be provided, and the hatch is sealed with the vacuum cover 11; the CNC motion assembly 3 is connected to the inner top surface of the vacuum cover 11, and the ultrasonic brazing assembly 2 Connected with the CNC motion assembly 3, the heating assembly 4 is connected to the bottom surface of the vacuum cover 11, the controller 5 is connected with the vacuum assembly 1, the CNC motion assembly 3, the heating assembly 4, the Ultrasonic brazing assembly 2 connections.

[0040] A vacuum-ultrasonic composite brazing device also includes a frame 6, the frame 6 is a table structure, including two layers, the vacuum a...

Embodiment 2

[0050] Such as figure 2 , image 3 As shown, in this embodiment, on the basis of the first embodiment above, the CNC motion assembly 3 includes a guide rail fixing seat 31, an X-axis guide rail 32, a Y-axis guide rail 33, and a Z-axis guide rail 34, and the guide rail fixing seat 31 is fixedly connected to On the top surface of the frame 6, the guide rail fixing base 31 is located on both sides of the frame 6, the Y-axis guide rail 33 is connected to the top of the guide rail fixing base 31, and the top of the Y-axis guide rail 33 has a protrusion. The bottom of the shaft guide rail 32 has a groove, and the X-axis guide rail 32 can slide along the Y-axis direction (ie, the front-to-back direction) to connect the top of the Y-axis guide rail 33. The side of the X-axis guide rail 32 is provided with a protrusion. The side of the Z-axis guide rail 34 has a groove, and the Z-axis guide rail 34 can slide along the X-axis direction (ie, the left-right direction) to connect the X-a...

Embodiment 3

[0053] Such as figure 1 , figure 2 As shown, on the basis of the second embodiment above, a vacuum-ultrasonic composite brazing device also includes a cooling assembly 8, the cooling assembly 8 is connected to the inner bottom surface of the vacuum cover 11, and the heating assembly 4 is connected to On the top surface of the cooling assembly 8 , the cooling assembly 8 is connected to the controller 5 .

[0054] The cooling assembly 8 includes a cooling housing 81, a water cooler 82, and a cooling pipe 83. The cooling housing 81 is connected to the inner bottom surface of the vacuum cover 11, and the heating assembly 4 is connected to the cooling housing 81. On the top surface, the cooling pipe 83 is arranged in the cooling housing 81 in a curved manner. The bending method is uniformly arranged back and forth, mainly to increase the length of the cooling pipe 83. Other methods are also available. The cooling The pipe 83 is circularly connected to the water cooler 82 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com