A ring die for feed pellet mill with inner sinking and chamfering holes

A granulator and ring die technology, which is applied in the direction of raw material extrusion granulation, etc., to achieve the effect of improving coagulation, high density, and beautiful material shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

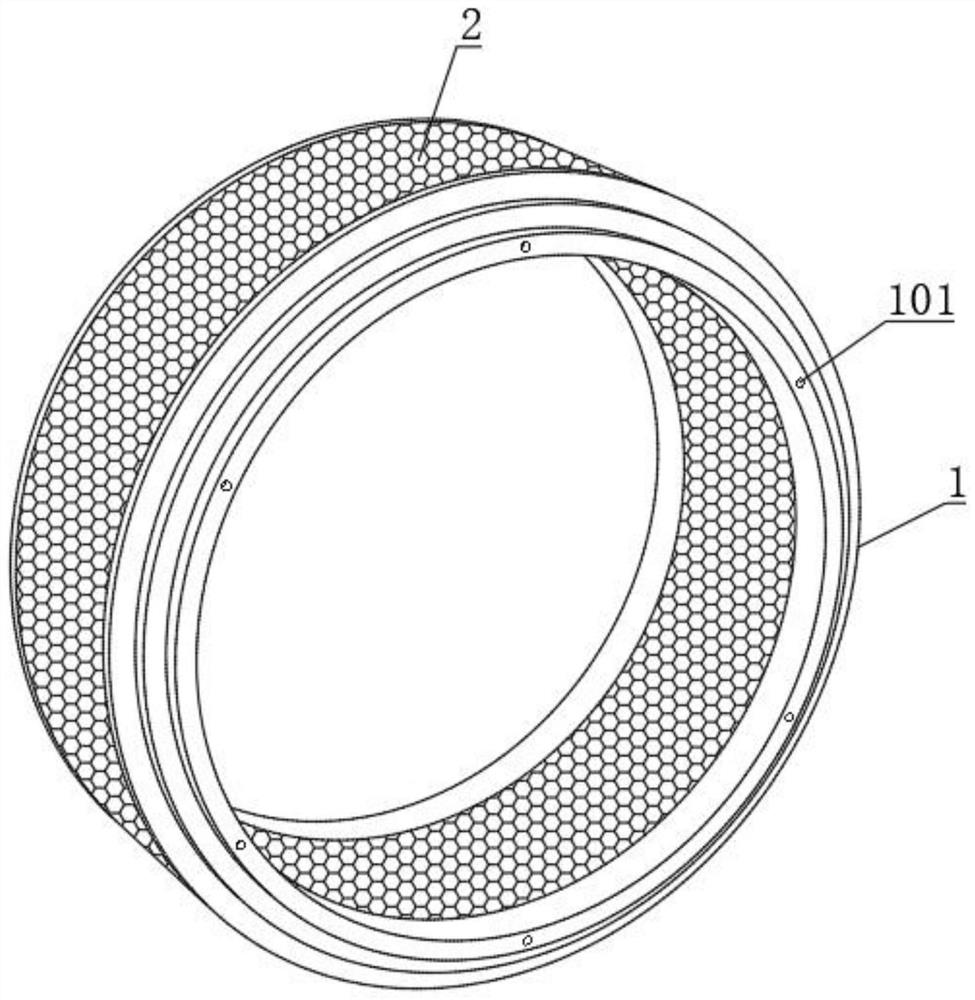

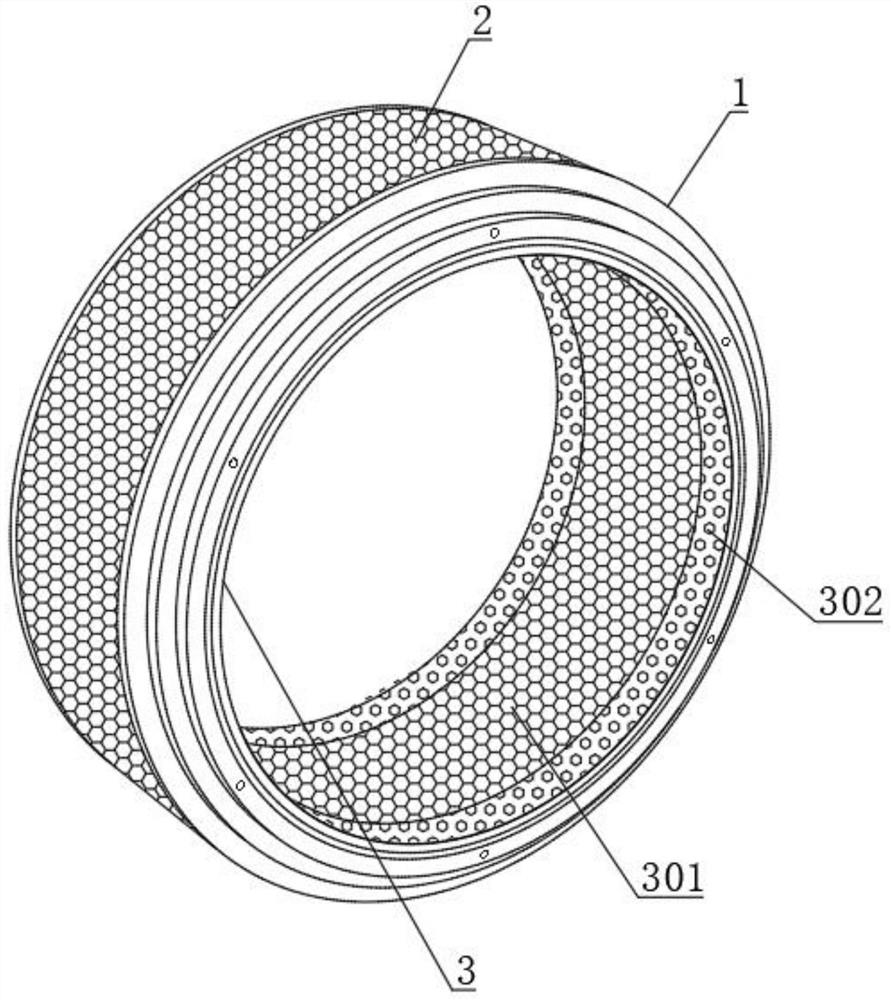

[0043] see figure 1 and Figure 4 , a ring die for an inner sinking chamfering hole type feed pellet machine, comprising a ring die main body 1, a plurality of evenly distributed inner sinking chamfering die holes 2 are opened on the ring die main body 1, and the inner sinking chamfering die holes 2 include The inner expansion hole 201, the straight hole 202 and the outer release hole 203 distributed sequentially from the inside to the outside, the inner expansion hole 201, the straight hole 202 and the outer release hole 203 are connected to each other, the diameter of the inner expansion hole 201 and the outer release hole 203 The diameters of the apertures gradually increase along the direction away from the straight hole 202. The angle between the generatrix of the inner wall of the inner expansion hole 201 and the vertical plane is 30°-60°. The included angle is 3°-7°. For example, during specific implementation, the inner expansion hole 201 can be set to 45°, and the ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com