Ship waste gas washing device

A technology for washing waste gas and ships, which is applied in the separation of dispersed particles, chemical instruments and methods, separation methods, etc., and can solve the problems of large space occupation, uneven distribution of washing liquid, and uneven liquid distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

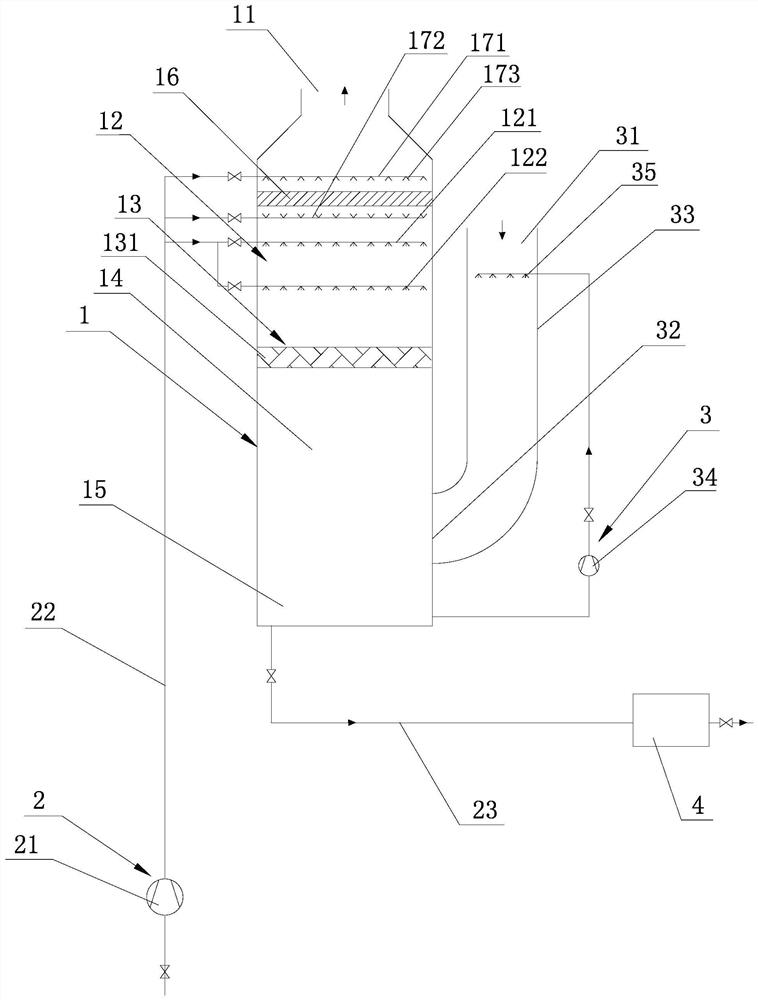

[0026] A kind of ship waste gas scrubbing device that present embodiment proposes, such as figure 1 As shown, it is composed of a washing tower 1, a washing liquid supply and drainage system 2, and a ship exhaust gas cooling system 3. The top of the washing tower 1 is provided with a ship exhaust gas outlet 11, and the washing tower 1 is provided with a spray layer washing area 12 and a packing layer. Washing area 13, the packing layer washing area 13 is located below the spray layer washing area 12, and the space below the packing layer washing area 13 in the washing tower 1 is divided into a ship exhaust gas cooling area 14 and a cooling liquid pool 15 from top to bottom (the cooling liquid pool 15 is built-in), the supply part of the washing liquid supply and drainage system 2 provides washing liquid for the spray layer washing area 12, and the discharge part of the washing liquid supply and drainage system 2 discharges the washing waste water, and the ship waste gas cooling...

Embodiment 2

[0032] A kind of ship waste gas scrubbing device that present embodiment proposes, such as figure 2 As shown, the internal structure of the scrubber 1 and the structure of the ship exhaust gas cooling system 3 are the same as the ship exhaust gas scrubber of Embodiment 1, the difference lies in the structure of the washing liquid supply and drainage system 2, the washing liquid supply and drainage system 2 is external, The supply part of the cleaning solution supply and drainage system 2 includes a fresh lye storage tank 24, a metering pump 25, an lye cooler 26, a cleaning solution pump 21, and a cleaning solution main pipe 22, and the discharge part of the cleaning solution supply and drainage system 2 includes spent lye Discharging pipe 27, the supply part and the discharge part of washing liquid supply and drainage system 2 share washing waste water outlet pipe 23 and lye buffer tank 28, and the inlet of washing waste water outlet pipe 23 is connected with the bottom of was...

Embodiment 3

[0034] A kind of ship waste gas scrubbing device that present embodiment proposes, such as image 3 As shown, the internal structure of the washing tower 1 is the same as that of the ship exhaust gas scrubbing device in Embodiment 1, the difference lies in the structure of the ship exhaust gas cooling system 3 and the washing liquid supply and discharge system 2 . The exhaust gas cooling area 14 of the ship is provided with a ventilating liquid blocker 18 which allows the exhaust gas from the ship to pass from bottom to top and prevents the washing liquid from passing through, and the washed liquid falls on the venting liquid blocker 18; Cooler 33, external coolant pump 34, external coolant replenishment pipe 36, built-in coolant pool 15, ship exhaust gas inlet 31 is arranged on the top of cooler 33, and exhaust gas inlet 32 is arranged on cooler 33 At the end of the cooler 33, a plurality of coolant nozzles 35 for atomizing coolant are uniformly arranged in the cooler 33. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com