Method for improving doping uniformity of semiconductor laser

A laser and semiconductor technology, applied to the structure of the active region, gaseous chemical plating, metal material coating process, etc., can solve the problem that the uniformity of doping concentration cannot meet the required requirements, and achieve the promotion of mass production, Effect of improving doping uniformity and reducing the influence of doping unevenness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

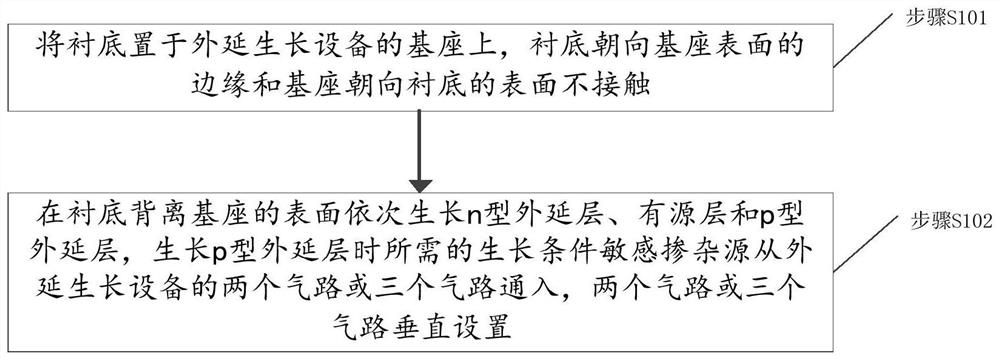

[0032] An embodiment of the present invention provides a method for improving the doping uniformity of a semiconductor laser, such as figure 1 As shown, the method includes the following steps:

[0033] Step S101: The substrate is placed on the base of the epitaxial growth equipment, and the edge of the substrate facing the surface of the base is not in contact with the surface of the base facing the substrate; in a specific embodiment, the epitaxial growth equipment can be made of metal Organic compound chemical vapor deposition (Metal-organic Chemical Vapor Deposition, MOCVD) equipment.

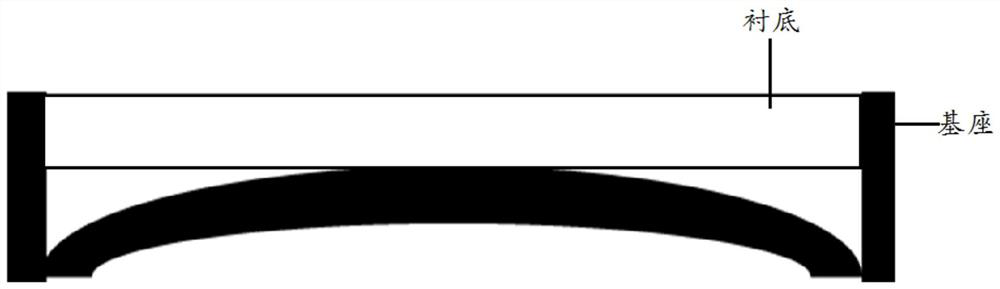

[0034] In order to keep the edge of the substrate out of contact with the base, in one embodiment, before placing the substrate on the base, a thermal expansion layer can be deposited on one side of the substrate, and the thermal expansion coefficient of the thermal expansion layer is greater than that of the substrate. When the substrate is placed on the base of the epitaxial growth equip...

Embodiment 2

[0043] The method for improving the doping uniformity of a semiconductor laser provided by an embodiment of the present invention is described by taking an edge-emitting semiconductor laser as an example, wherein the edge-emitting semiconductor laser is a 980 nm edge-emitting semiconductor laser.

[0044] First, adjust the temperature uniformity of the substrate surface during epitaxial growth. Specifically, silicon nitride can be deposited on the back of the gallium arsenide substrate by using PECVD or LPCVD process. The thickness of the deposited silicon nitride is 100nm-2000nm. By adjusting the substrate parameters of silicon nitride, the thermal expansion coefficient of silicon nitride can be made greater than the thermal expansion coefficient of the gallium arsenide substrate, when the gallium arsenide substrate is placed on the base of the MOCVD equipment for heating, the silicon nitride film will produce compressive strain, and the gallium arsenide substrate will become ...

Embodiment 3

[0049] The method for improving the doping uniformity of a semiconductor laser provided by the embodiment of the present invention is described by taking a vertical cavity surface emitting semiconductor laser as an example, wherein the vertical cavity surface emitting semiconductor laser is a 940nm vertical cavity surface emitting semiconductor laser.

[0050] First, adjust the temperature uniformity of the substrate surface during epitaxial growth. Specifically, silicon nitride can be deposited on the back of the gallium arsenide substrate by using PECVD or LPCVD process. The thickness of the deposited silicon nitride is 100nm-2000nm. By adjusting the substrate parameters of silicon nitride, the thermal expansion coefficient of silicon nitride can be made The thermal expansion coefficient of the gallium arsenide substrate is greater than that of the gallium arsenide substrate. When the gallium arsenide substrate is placed on the base of the MOCVD equipment for heating, the sil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com