Light-emitting diode display and manufacturing method thereof

A technology of light-emitting diodes and manufacturing methods, which is applied in the direction of semiconductor devices, static indicators, electric solid devices, etc., can solve problems such as increasing the complexity of circuit design and affecting the area utilization rate of high-resolution display screens, and achieve the reduction of circuit Complexity, increase transfer success rate, and reduce the effect of transfer times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

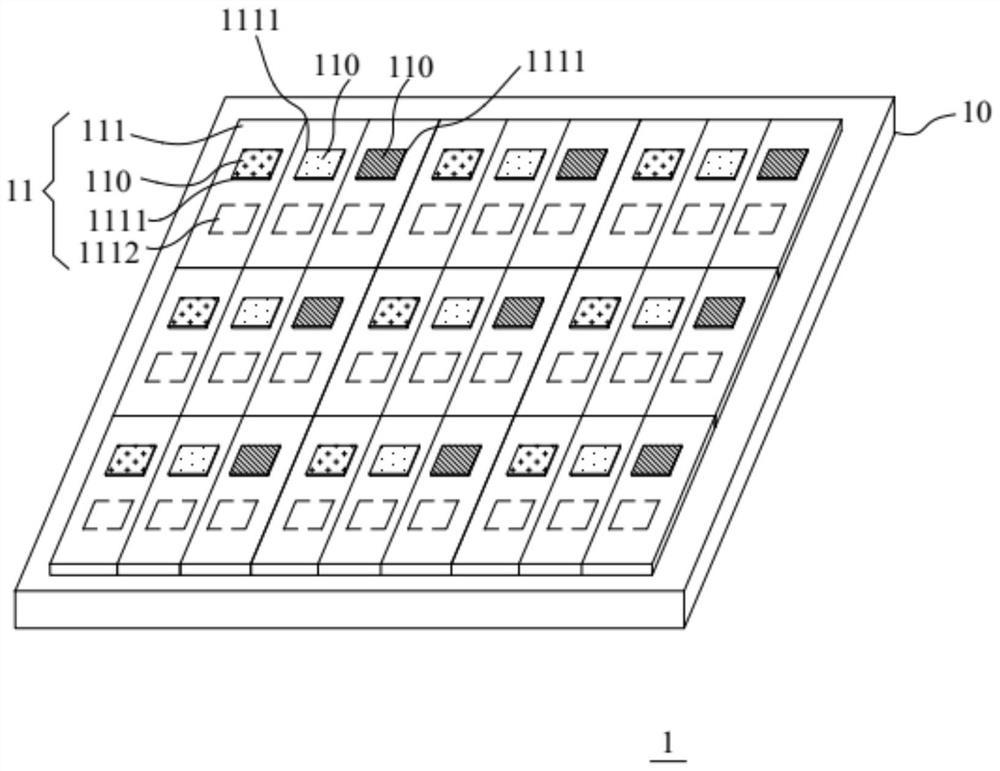

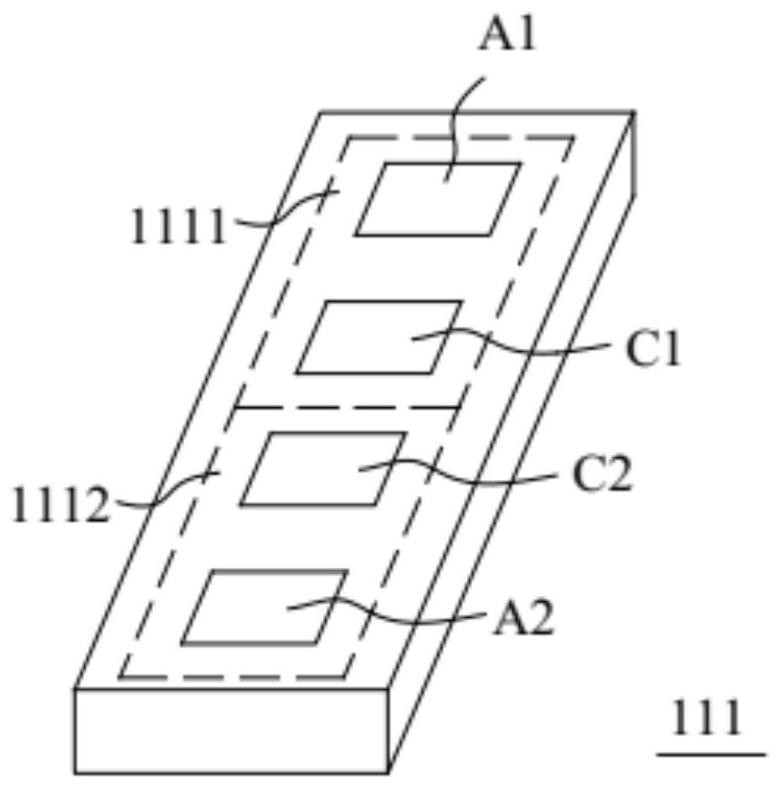

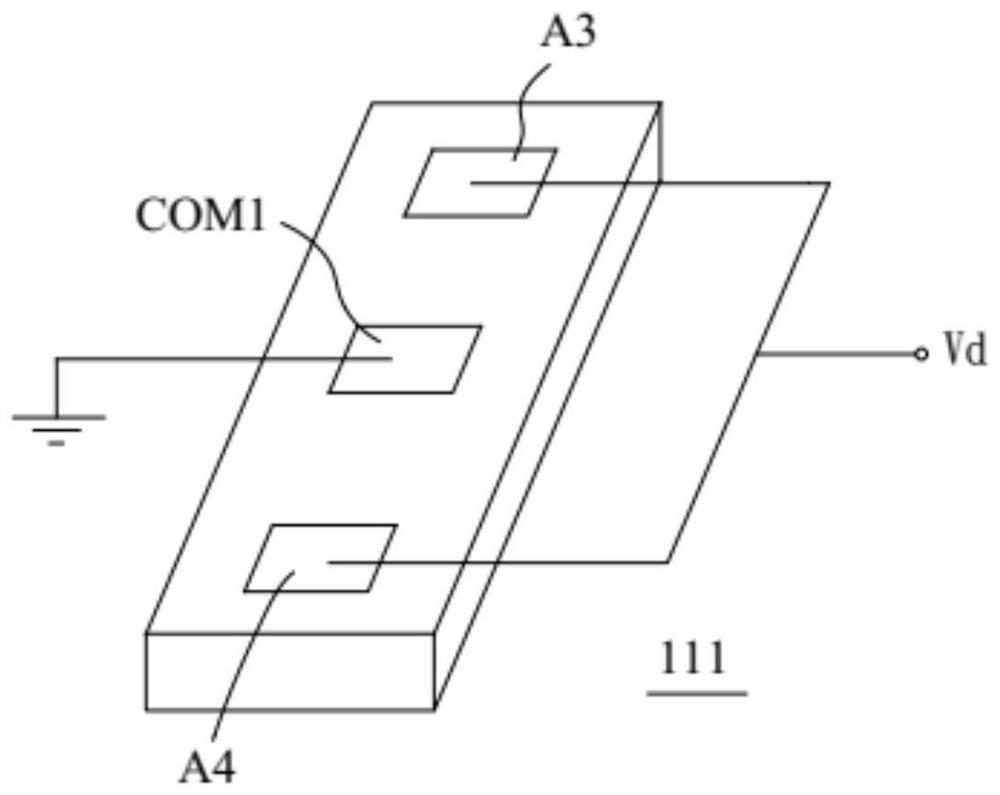

[0143] Embodiments of the present invention will be further explained with the help of related figures below. Wherever possible, the same reference numerals have been used throughout the drawings and description to refer to the same or similar components. In the drawings, the shape and thickness may be exaggerated for the sake of simplification and convenient labeling. It should be understood that elements not particularly shown in the drawings or described in the specification are forms known to those skilled in the art. Those skilled in the art can make various changes and modifications according to the content of the present invention.

[0144] When an element is referred to as being "on", it can generally mean that the element is directly on other elements, or there may be other elements present in between. Conversely, when an element is referred to as being "directly on" another element, it cannot have the other element in between. As used herein, the word "and / or" inc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com