Glass fiber reinforced plastic flexible composite pipe, production device and production method

A technology for flexible composite pipes and production equipment, applied in the direction of hoses, pipes, tubular objects, etc., can solve the problems of limited process preparation conditions, pipeline sealing and safety affecting the use effect, etc., to reduce the number of joints, facilitate processing and Continuous, time-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

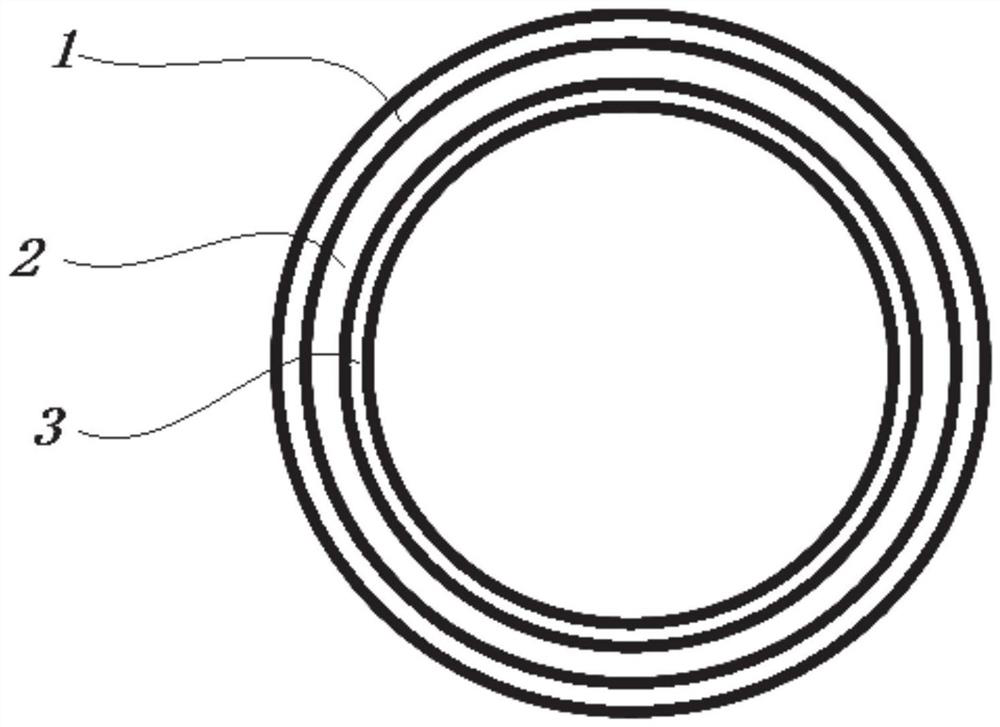

[0030] In a typical embodiment of the present invention, such as figure 1 As shown, this embodiment discloses a flexible composite pipe made of glass fiber reinforced plastics, which is composed of a three-layer structure. From the inside to the outside, there are respectively a thermoplastic resin lining layer 3, a glass fiber reinforced plastic reinforcement layer 2, and a thermoplastic resin outer protective layer 1. The three-layer structure The fiberglass reinforced layer 2 includes glass fibers wound outside the thermoplastic resin lining layer, the thermosetting resin and thermoplastic resin mixture attached to the glass fibers, and the thermoplastic resin outer protective layer 1 is attached to the fiberglass reinforced layer 2 outer thermoplastic resin layer.

[0031] Wherein, the thermoplastic resin lining layer 3 is prepared by continuously extruding the thermoplastic resin lining pipe online through an extruder, and the thermoplastic resin can be PE, PP, PA, PVDF, ...

Embodiment 2

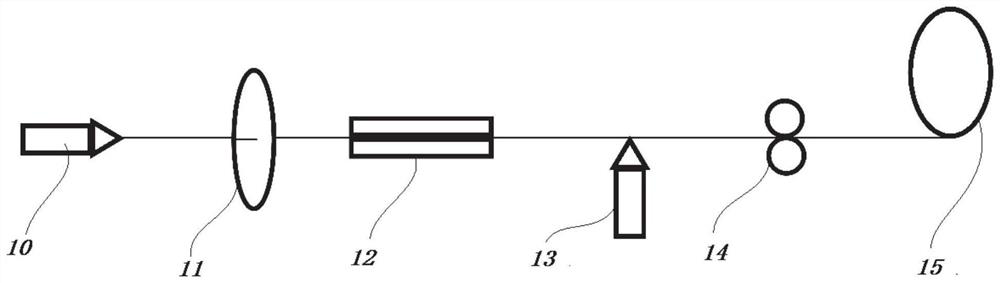

[0038] In a typical embodiment of the present invention, such as figure 2 As shown, this embodiment discloses a production device for FRP flexible composite pipe, which includes a lining pipe extruder 10, a winding machine 11, a heating oven 12, a coating extruder 13, a tractor 14 and a winding Large plate 15, wherein, the lined pipe extruder 10 is used to extrude a thermoplastic resin lined pipe, the central hole of the winding machine 11 is used for the thermoplastic resin lined pipe to pass through, and the heating oven 12 is used for At the same time, the curing of the thermosetting resin and the bonding of the thermoplastic resin are completed, the covering extruder 13 is used to extrude the outer protective layer 1 of the thermoplastic resin, the tractor 14 is used to draw the finished pipe, and the winding The large plate 15 is used for winding the finished product of the FRP composite flexible pipe.

[0039] Those skilled in the art can understand that the lined pipe...

Embodiment 3

[0044] In a typical implementation of the present invention, this embodiment discloses a production method of a flexible FRP composite pipe, using a production device for a FRP flexible composite pipe as described in Example 1, comprising the following steps:

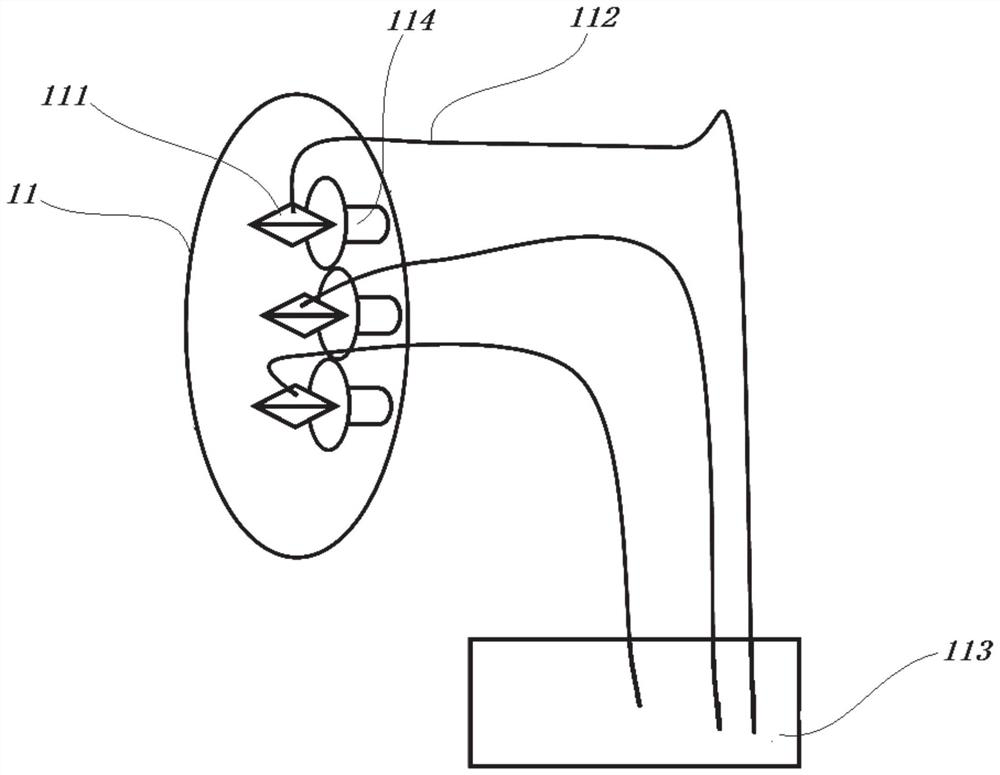

[0045] 1) A plurality of yarn bobbins 114 and dipping nozzles 111 are simultaneously arranged on a winding machine 11, each yarn bobbin 114 is matched with a dipping nozzle 111, so that the lining tube passes through the center hole of the winding machine 11;

[0046] 2) The dipping nozzle 111 draws the resin liquid from the dipping tank 113 through the pipeline, and combines with the fiber bundles from the yarn drum 114 passing through the dipping nozzle 111, and the impregnated fiber bundles are in accordance with the set angle On-line continuous winding on the inner liner;

[0047] 3) Start the oven to realize the curing of the thermosetting resin and at the same time realize the bonding of the thermoplastic resin; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com