Rotary valve assembly for digital hydraulic oil cylinder and corresponding mechanical feedback digital hydraulic oil cylinder

A digital hydraulic and mechanical feedback technology, applied in mechanical equipment, servo motor components, fluid pressure actuators, etc., can solve problems such as poor electrical interference resistance, small oil pressure adjustment range, and extremely high requirements for system pressure stability. Achieve the effects of improving anti-interference ability, reducing energy loss, and reducing viscosity requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the technical solutions and advantages of the present invention clearer, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

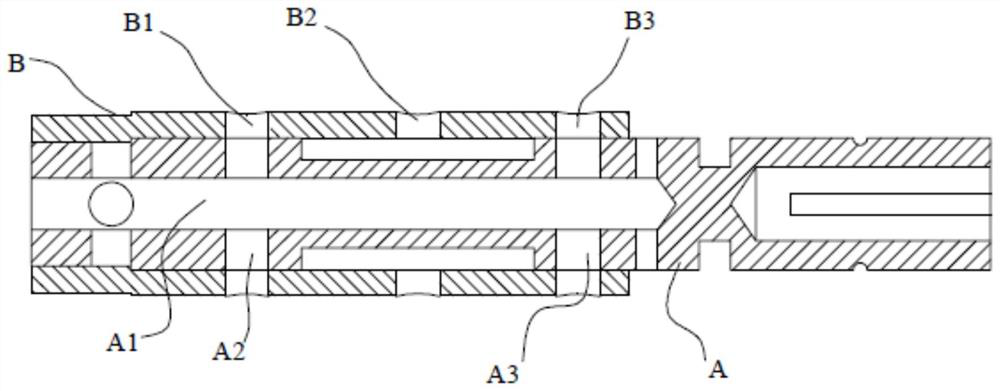

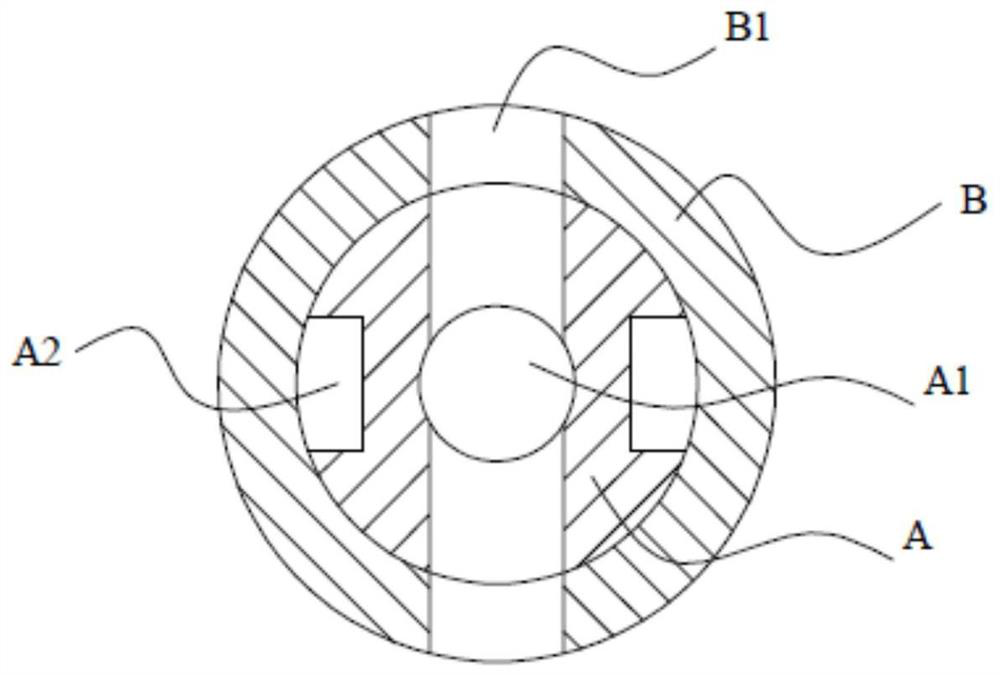

[0024] Such as figure 1 As shown, a rotary valve assembly for a digital hydraulic cylinder includes a valve core A and a valve sleeve B assembled outside the valve core A.

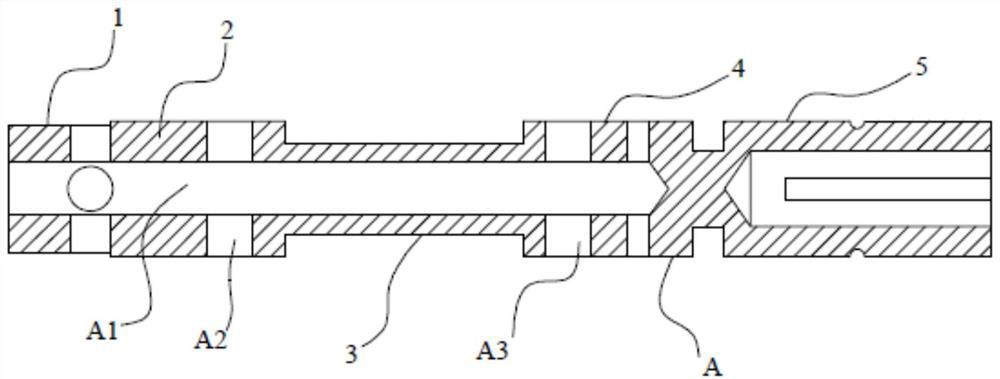

[0025] Specifically, such as figure 2 As shown, the spool A is a shaft-shaped rotator. From left to right, it is the feedback connection end 1, the first oil distribution section 2, the second oil distribution section 3, the third oil distribution section 4, and the drive connection shaft 5. The axial center of the core A is provided with the first passage A1, the first oil distribution section 2 is provided with the second passage A2 along the radial direction, the third oil distribution section 4 is provided with the third passage A3 along the radial direction, the first oil dist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com