Preparation method of flame-retardant cool cellulose fibers for summer curtains

A cellulose fiber and cooling technology, applied in the field of flame retardant cool cellulose fiber and its preparation, can solve the problems of poor antibacterial performance, poor insulation effect of curtains, and products that cannot be naturally decomposed, and achieves enhanced flame retardant effect, good inhibition effect, etc. Bacterial effect, good bacteriostatic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

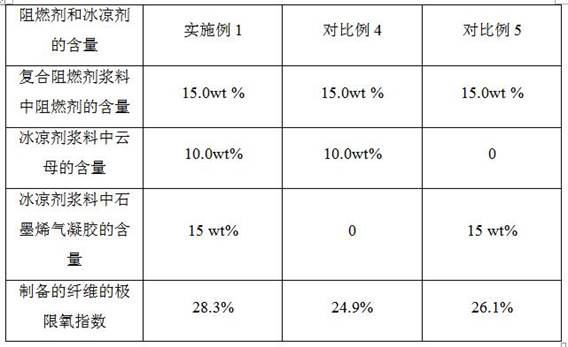

Examples

Embodiment 1

[0038] 1. Preparation of composite flame retardant slurry

[0039] Add the pyrophosphate ester powder with a particle size of <0.6 μm to deionized water at 40°C, add the dispersant NNO, stir for 2 hours at the speed of the mixer at 1000r / min, and grind for 4 hours with a grinder at the speed of 4000r / min , and then add magnesium hydroxide microcapsules and rare earth lanthanum chloride microcapsules, and continue to stir for 1 hour at the speed of the mixer at a speed of 2000 r / min, and the particle size D90 of the slurry is detected to be 1.967 μm.

[0040] Wherein, the flame retardant in the slurry is pyrophosphate and magnesium hydroxide microcapsules, and the ratio of the two is 15:1, wherein the wall material of the magnesium hydroxide microcapsules is melamine formaldehyde resin, and the magnesium hydroxide content in the capsule is 60wt %. The content of flame retardant in the composite slurry is 15.0wt%, the content of rare earth lanthanum chloride microcapsules is 1....

Embodiment 2

[0050] 1. Preparation of composite flame retardant slurry

[0051] Add silicon-ammonium pyrophosphate with a particle size of <0.6μm into deionized water at 50°C, add the dispersant sodium hexametaphosphate, stir for 1.0 hour at the speed of the mixer at 2000r / min, and use a grinder at the speed of 4500r / min Grind for 3 hours, then add magnesium hydroxide microcapsules and lanthanum chloride microcapsules, and continue stirring for 80 minutes at the speed of the mixer at 1500 r / min. The particle size D90 of the slurry is detected to be 1.876 μm.

[0052] Among them, the flame retardant in the slurry is silicon-ammonium pyrophosphate and magnesium hydroxide microcapsules, the ratio of the two is 15:2, and the wall material of the magnesium hydroxide microcapsules is melamine formaldehyde resin, and the magnesium hydroxide content in the capsules is 80wt%. The content of flame retardant in the composite slurry is 25.0wt%, the content of rare earth lanthanum chloride microcapsul...

Embodiment 3

[0062] 1. Preparation of composite flame retardant slurry

[0063] Add the melamine resin with a particle size of <0.6μm into deionized water at 45°C, add the dispersant, stir for 1.0 hour at the speed of the mixer at 1000r / min, and grind for 2 hours at the speed of 5000r / min with the grinder , then add magnesium hydroxide microcapsules and rare earth lanthanum chloride microcapsules, and continue to stir for 2 hours at the speed of the mixer at a speed of 1500r / min, and the particle size D90 of the slurry is detected to be 1.838 μm.

[0064] Wherein, the flame retardant in the slurry is melamine resin and magnesium hydroxide microcapsules, the ratio of the two is 15:1, wherein the wall material of the magnesium hydroxide microcapsules is melamine formaldehyde resin, and the content of magnesium hydroxide in the capsule is 70wt %. The content of flame retardant in the composite slurry is 18.0wt%, the content of rare earth lanthanum chloride microcapsules is 2.0wt%, and the co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com