Automatic ultrasonic shot blasting device and method for processing metal sheet

A technology of ultrasonic shot peening and metal sheet, which is applied in heat treatment equipment, heat treatment process control, manufacturing tools, etc. It can solve physical discomfort, the speed and path of shot peening cannot be accurately controlled, and the impact pins of the shot blasting gun array cannot guarantee verticality. Problems such as impacting the surface of the material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

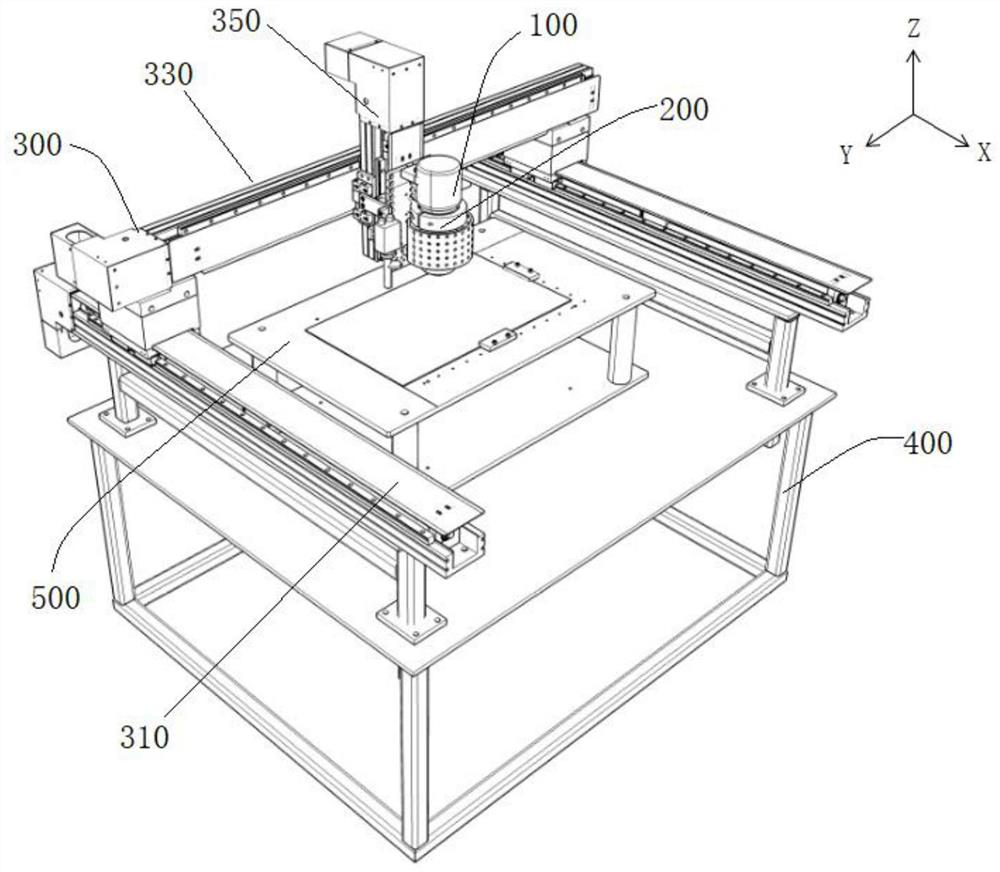

[0060] figure 1 It is an overall schematic diagram of an automatic ultrasonic shot peening device for processing thin metal plates of the present invention.

[0061] Such as figure 1 As shown, the automatic ultrasonic shot peening device for processing metal sheets of the present invention includes: an ultrasonic shot peening gun 100 , a shot peening gun fixing mechanism 200 , a moving mechanism 300 , a frame stabilizing mechanism 400 and a metal sheet fixing mechanism 500 .

[0062] The ultrasonic shot-peening gun 100 performs shot-peening treatment on the small metal thin plate to be treated.

[0063] The shot peening gun fixing mechanism 200 fixes the ultrasonic shot peening gun 100 on the moving mechanism 300 .

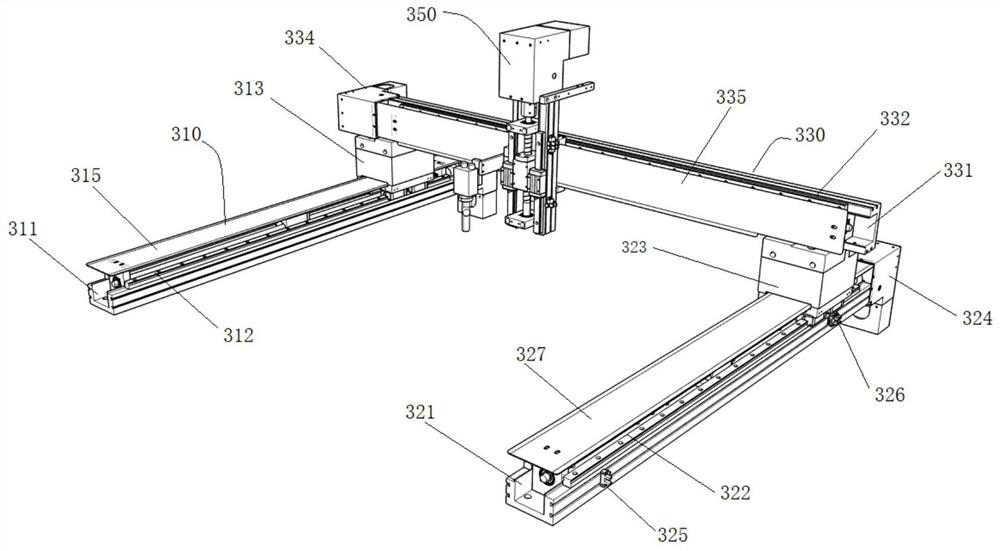

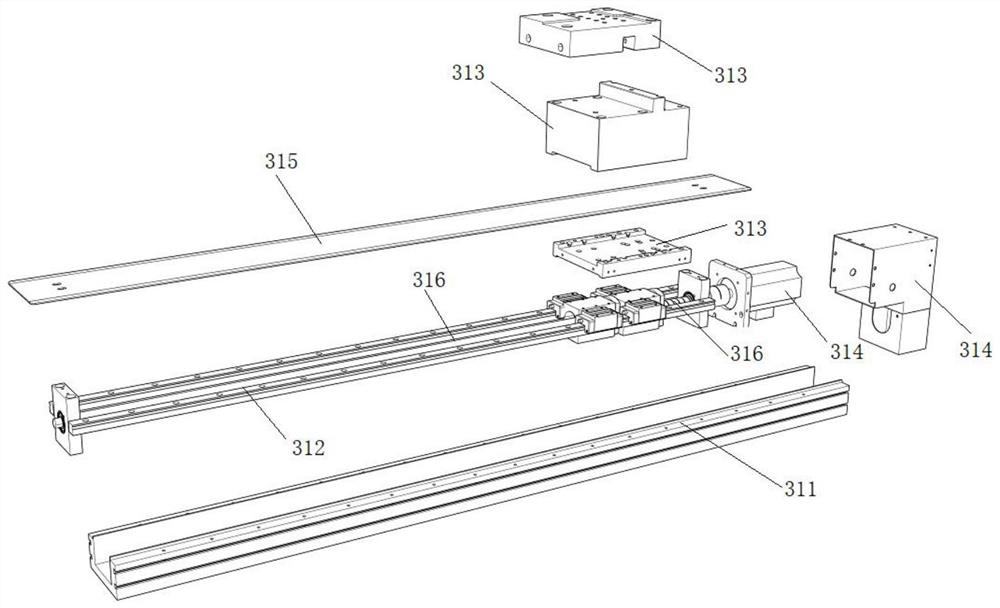

[0064] The motion mechanism 300 can move along the X-axis, Y-axis or Z-axis direction, and drive the shot-peening gun fixing mechanism 200 to move along the X-axis, Y-axis or Z-axis direction, so that the ultrasonic shot-peening gun 100 can move along the X-axis...

Embodiment 2

[0084] The only difference from Embodiment 1 is that the spray gun fixing mechanism 200 of Embodiment 2 also includes a rubber damping ring 250 and a muzzle protection cover 260 . Such as figure 1 and Figure 7 As shown, the rubber shock absorbing ring 250 is located between the spray gun positioning fastening bracket 230 and the muzzle fastening bracket 240 . The muzzle protection cover 260 is connected with the spray gun fixing plate 210 , and the muzzle protection cover 260 covers the periphery of the muzzle fastening frame 240 to protect the ultrasonic shot peening gun 100 . Evenly distributed small holes are arranged on the muzzle protection cover 260 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com