20CrMnMo open gear, detection method thereof and heat treatment method for reducing cracks of blank forging of 20CrMnMo open gear

A heat treatment method and open gear technology, applied in heat treatment furnaces, heat treatment equipment, wheels, etc., can solve problems such as difficulty in troubleshooting, achieve the effect of reducing crack defects and improving the qualified rate of finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

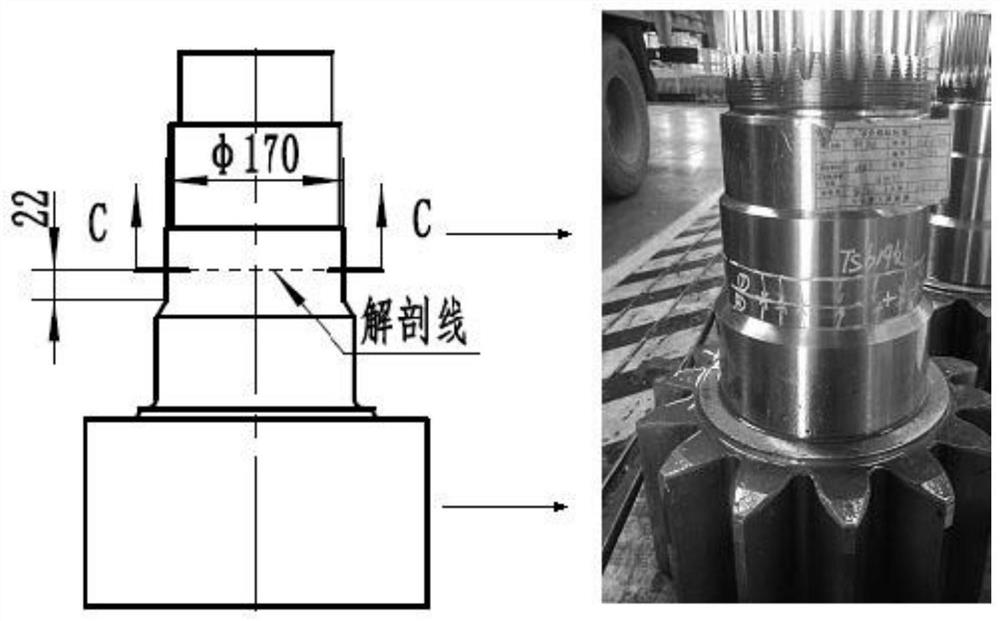

[0086] Now, the present invention will be described in further detail in conjunction with the accompanying drawings and embodiments.

[0087] A heat treatment method for reducing cracks in 20CrMnMo open gear blank forgings, specifically comprising the following steps:

[0088] Step 1: Blank forgings: Select a billet made of 20CrMnMo with a specification of 300×300mm, as a blank forging of an open gear, and quench and temper the blank forging,

[0089] Step 2: Put the blank forging in step 1 into the furnace to heat, and then forge after heating. The initial forging temperature is 1200°C, the final forging temperature is 800°C, and the forging ratio is 7.5, specifically:

[0090] (2.1) The billet is drawn up to 600mm, upsetting to 300mm,

[0091] (2.2) Pull out again to 600mm, upsetting to 300mm,

[0092] (2.3) Then pull out and round to

[0093] (2.4) Extended and restructured as small head,

[0094] (2.5) Braised die forging molding,

[0095] (2.6) pit cold,

[0096...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com