High-pressure water jet device based on welding residual stress regulation and control and using method

A high-pressure water jet, residual stress technology, applied in the direction of abrasive feeding device, used abrasive processing device, measuring device, etc., can solve the problems of lack of, reduce welding residual stress, lack of pressure testing device, etc., to ensure Accuracy, simple structure, guarantee the effect of strengthening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

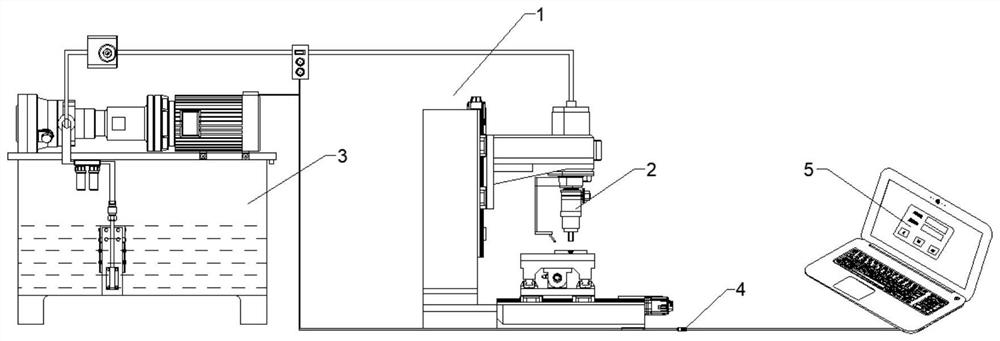

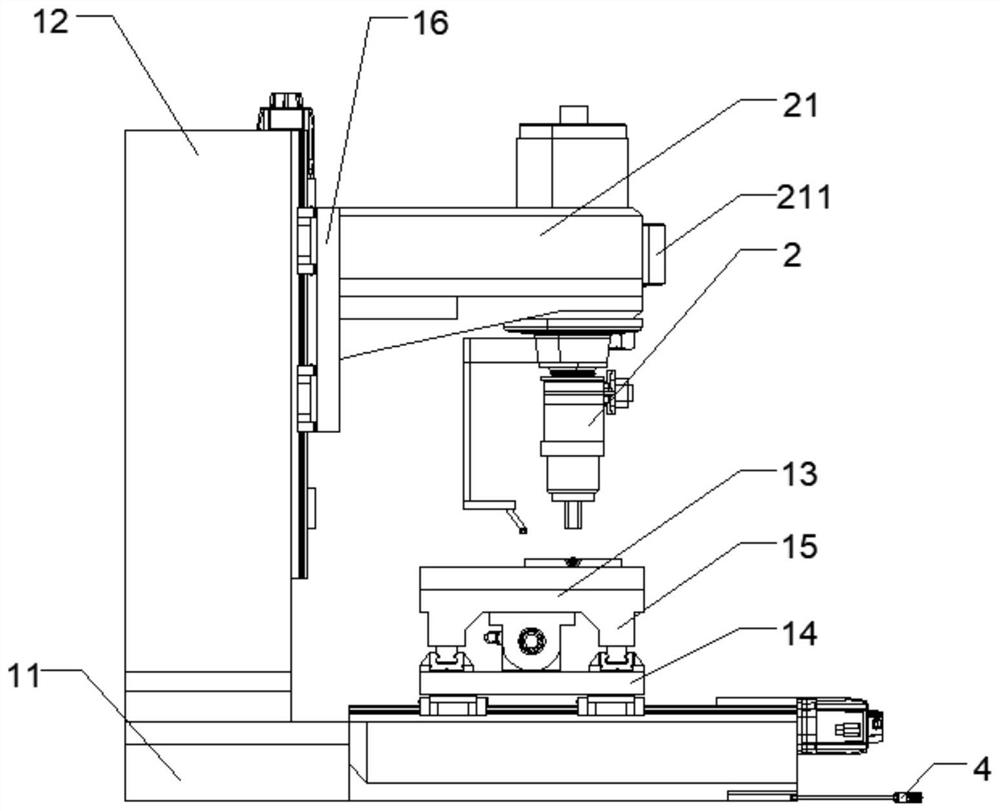

[0042] refer to figure 1 , this embodiment provides a high-pressure water jet device based on welding residual stress control, including a body 1, a nozzle system 2, a high-pressure generating system 3, a pressure transmitter 4 and a computer 5, and the high-pressure generating system 3 is arranged on a part of the body 1 Side, the body 1 includes a base 11, a column 12 and a worktable 13, the column 12 is vertically fixed on one side of the base 11, the workbench 13 is arranged above the base 11, the nozzle system 2 is arranged on the side of the column 12 through the nozzle fixing table 21 and Located above the workbench 13 , the nozzle system 2 is connected to the high pressure generating system 3 through pipelines, the pressure transmitter 4 is arranged on the side of the base 11 , and the pressure transmitter 4 is connected to the computer 5 .

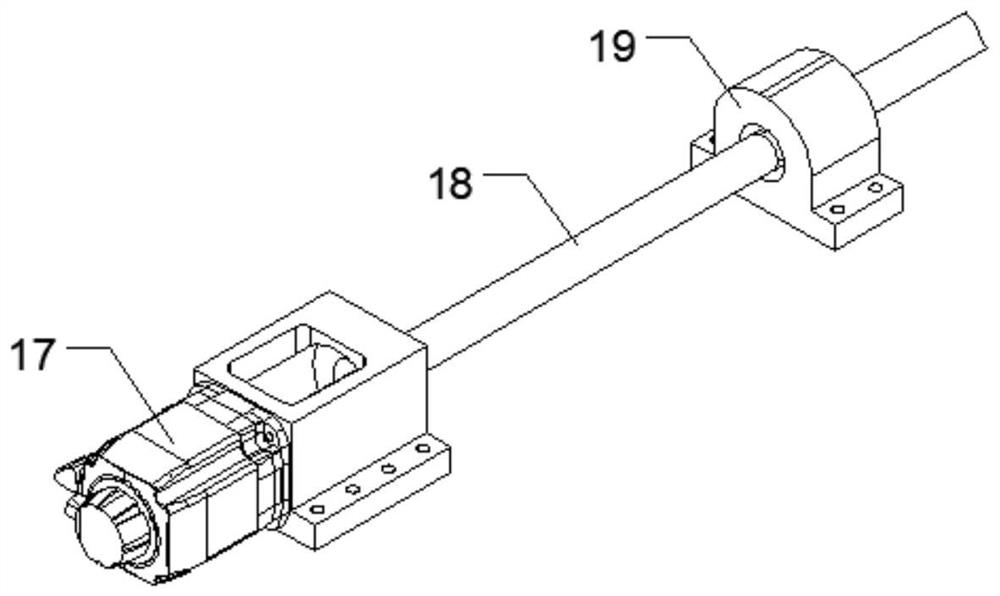

[0043] refer to figure 2 and image 3 The above-mentioned body 1 also includes an X-direction slide 14, a Y-direction slide 1...

Embodiment 2

[0061] The difference between this embodiment 2 and embodiment 1 is that the structure of a high-pressure water jet device based on welding residual stress regulation provided by this embodiment is the same as that of embodiment 1. In this embodiment, the high-pressure water jet operation is performed on the welded components When it is detected that the actual effective water jet pressure value received by the welded component deviates greatly from the required theoretical water jet pressure range, the operator controls the water jet pressure generated in the high pressure generating system 3 to remain unchanged, and is controlled by the computer 5 The distance between the nozzle system 2 and the welded component is used to adjust the actual effective water jet pressure value received by the welded component, and the distance measuring sensor simultaneously records the distance between the nozzle 24 and the welded component. For example, when the actual effective water jet pre...

Embodiment 3

[0063] The difference between this embodiment 3 and embodiment 1 and embodiment 2 is that no welding components are placed on the workbench in this embodiment, and the film pressure distribution sensor 61 is used to measure the high-pressure water jet directly acting on the target surface of the film pressure distribution sensor 61 The actual impact pressure data on the surface and the total high-pressure water jet impact pressure data detected by the metal resistance strain gauge 64 can obtain the actual impact pressure distribution curve to analyze the actual pressure distribution of the high-pressure water jet on the target surface and the high-pressure water jet along the jet flow. The gradual attenuation from the center to the surrounding area, the actual effective water jet pressure and the actual effective water jet area of the jet center can be obtained through the actual pressure distribution curve, as shown in Figure 9 As shown, the abscissa is the distance from th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com