Nickel phosphide-zirconium phosphate composite catalyst with mesoporous structure as well as preparation method and application thereof

A composite catalyst and mesoporous structure technology, applied in catalyst activation/preparation, physical/chemical process catalysts, phosphorus compounds, etc., can solve the problems of large particles of active components, easy loss of active components, poor stability, etc. Simple, promote industrial application, promote the effect of hydrodeoxygenation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Preparation of simple nickel phosphide:

[0040] (1) Take by weighing 4.653g nickel nitrate hexahydrate at room temperature, join in the beaker containing 100mL deionized water, stir vigorously for 10min and then ultrasonic for 10min until the nickel nitrate solid is completely dissolved to obtain a clear and transparent green solution, which is referred to as solution A; Add 2.536g of diammonium hydrogen phosphate into a beaker containing 60mL of deionized water, and stir vigorously for 10 minutes to obtain a clear and transparent colorless solution, which is designated as solution B. Solution B was added dropwise to solution A under vigorous stirring, and continued stirring and aging for 1 h after the dropwise addition was completed. After the stirring, the obtained green suspension was transferred to a polytetrafluoroethylene-lined hydrothermal reaction kettle, and hydrothermally reacted at 180°C for 24 hours. After natural cooling to room temperature, the sample was...

Embodiment 2

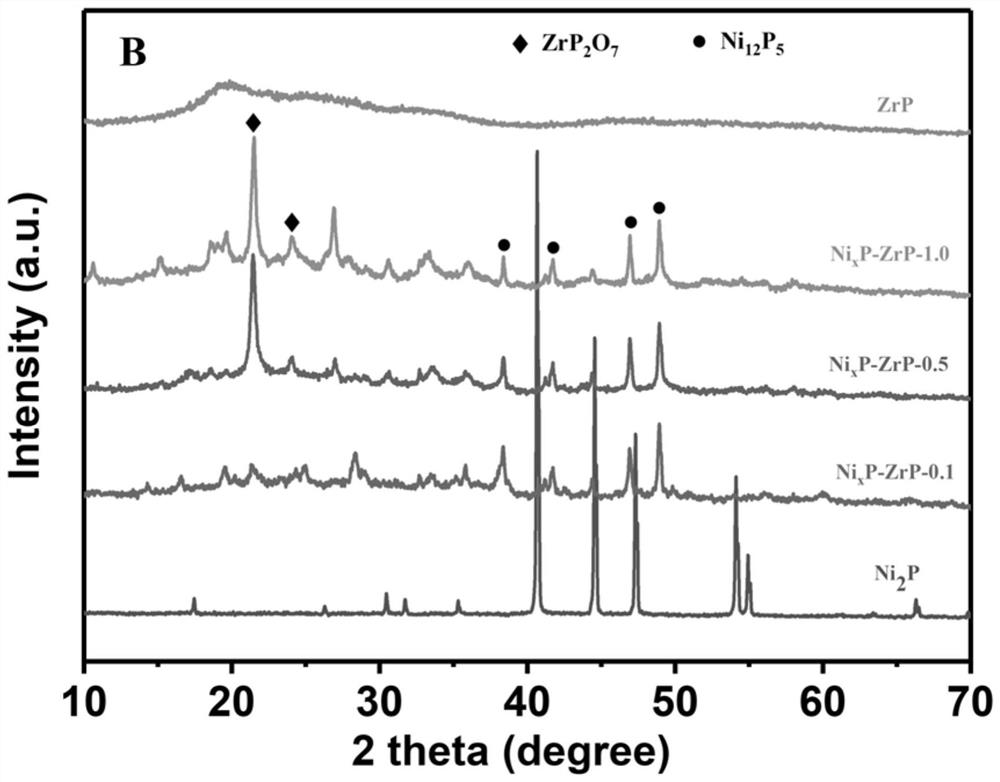

[0044] Ni x Preparation of P-ZrP-0.1 (Ni x P-ZrP represents nickel phosphide-zirconium phosphate composite catalyst; 0.1 represents the molar ratio of Zr and Ni in the catalyst, i.e. Zr / Ni=0.1):

[0045] (1) Weigh 4.653g of nickel nitrate hexahydrate and 0.687g of zirconium nitrate pentahydrate at room temperature, add them to a beaker containing 100mL of deionized water, stir vigorously for 10min and then ultrasonicate for 10min until the solid is completely dissolved to obtain a clear and transparent green solution, record Make solution A; take 2.958g of diammonium hydrogen phosphate and add it to a beaker containing 60mL of deionized water, stir vigorously for 10min to obtain a clear and transparent colorless solution, which is designated as solution B. Solution B was added dropwise to solution A under vigorous stirring, and continued stirring and aging for 1 h after the dropwise addition was completed. After the stirring, the obtained green suspension was transferred to ...

Embodiment 3

[0049] Ni x Preparation of P-ZrP-0.5 (0.5 represents the molar ratio of Zr and Ni in the catalyst, i.e. Zr / Ni=0.5):

[0050] (1) Weigh 4.653g of nickel nitrate hexahydrate and 3.4346g of zirconium nitrate pentahydrate at room temperature, add them to a beaker containing 100mL of deionized water, stir vigorously for 10min and then sonicate for 10min until the solids are completely dissolved to obtain a clear and transparent green solution. Make solution A; take 5.0711g of diammonium hydrogen phosphate and add it into a beaker containing 60mL of deionized water, stir vigorously for 10min to obtain a clear and transparent colorless solution, which is called solution B. Solution B was added dropwise to solution A under vigorous stirring, and continued stirring and aging for 1 h after the dropwise addition was completed. After the stirring, the obtained green suspension was transferred to a polytetrafluoroethylene-lined hydrothermal reaction kettle, and hydrothermally reacted at 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com