A fuel cell composite proton exchange membrane and its preparation method

A proton exchange membrane and fuel cell technology, applied in fuel cells, electrolytes, circuits, etc., can solve the problems of reducing the thickness of proton exchange membranes, which are difficult and difficult, and achieve the effect of improving battery performance, reducing dosage and good hydrophilicity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] This embodiment prepares perfluorosulfonic acid resin / polytetrafluoroethylene / resveratrol (PFSA / PTFE / resveratrol) composite proton exchange membrane, and its preparation method comprises the following steps:

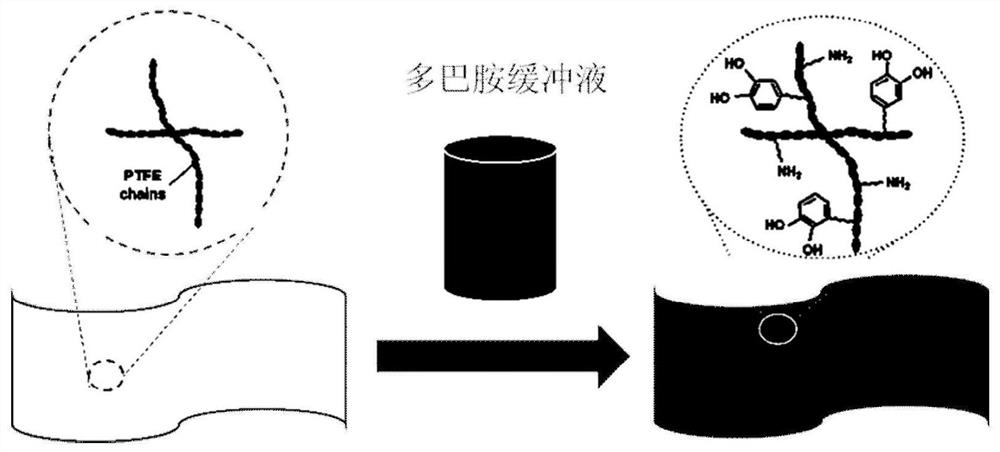

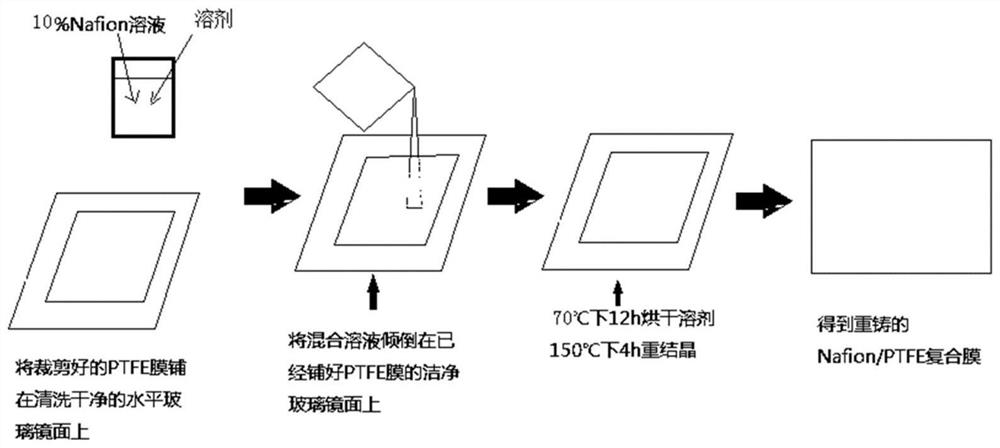

[0052] (1) Cut a piece of polytetrafluoroethylene (PTFE) film (PTFE) with a thickness of 10cm*10cm and a thickness of 7 μm with scissors, and fix it with a mold; take 500ml of ethanol solution in a crystallization dish with a diameter of 180mm, and slowly put the fixed PTFE into In the ethanol solution, let it stand and soak in a cool place for 24 hours; weigh 500mg of dopamine hydrochloride reagent and 788mg of trishydroxymethylaminomethane hydrochloride in a crystal dish with a diameter of 180mm, add 500ml of deionized water to prepare the solution, and add dropwise 1mol / L NaOH solution until the pH of the solution is 8.5; put the PTFE soaked for 24 hours into the dopamine buffer solution at a constant speed, keep it parallel to the horizontal plane, and place i...

Embodiment 2

[0059] This example prepares a perfluorosulfonic acid resin / polytetrafluoroethylene / quercetin (PFSA / PTFE / quercetin) composite proton exchange membrane, the preparation method of which is basically the same as in Example 1, except that step (1) 1mg of resveratrol in the drug was replaced by 1mg of quercetin.

Embodiment 3

[0061] This embodiment prepares perfluorosulfonic acid resin / polytetrafluoroethylene / resveratrol (PFSA / PTFE / resveratrol) composite proton exchange membrane, and its preparation method is basically the same as in Example 1, except that the step ( In 1), polytetrafluoroethylene is perpendicular to the horizontal plane in the dopamine buffer solution, and the included angle is 90°, and it is also perpendicular to the horizontal plane during the cleaning step.

[0062] The prepared proton exchange membrane is subjected to performance analysis, the results are as follows:

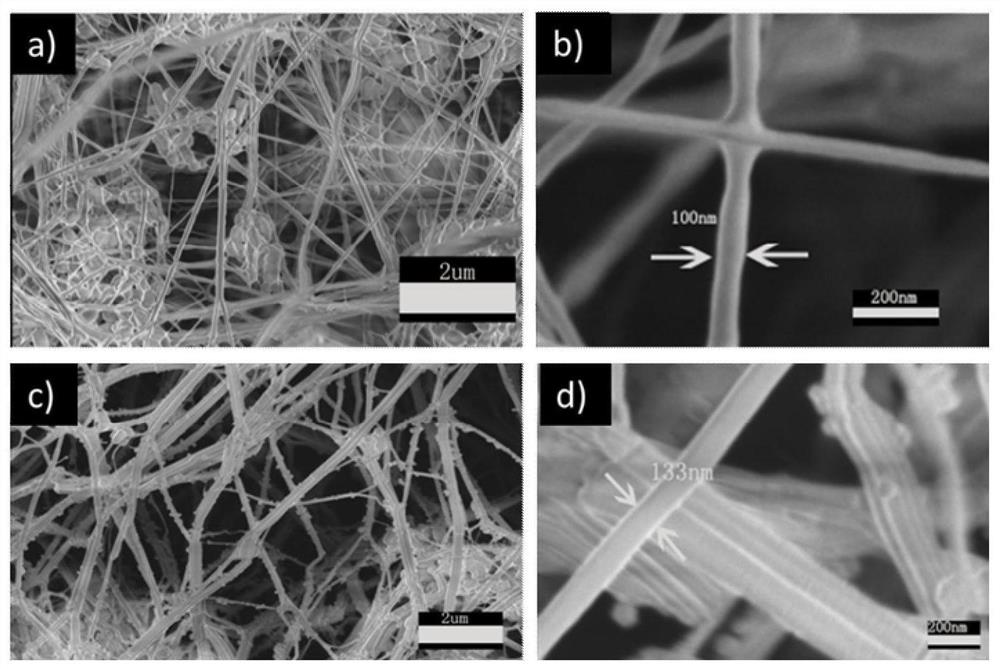

[0063] image 3 It is a scanning electron microscope image before and after modification of the polytetrafluoroethylene film in Example 1. It can be seen from Figure a) and c) that compared with before modification, the internal microporous structure of polytetrafluoroethylene after modification is orderly, indicating that polydopamine treatment can effectively optimize the internal microporous structure of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com