Daramic composite ionic conduction membrane, and preparation method and application thereof

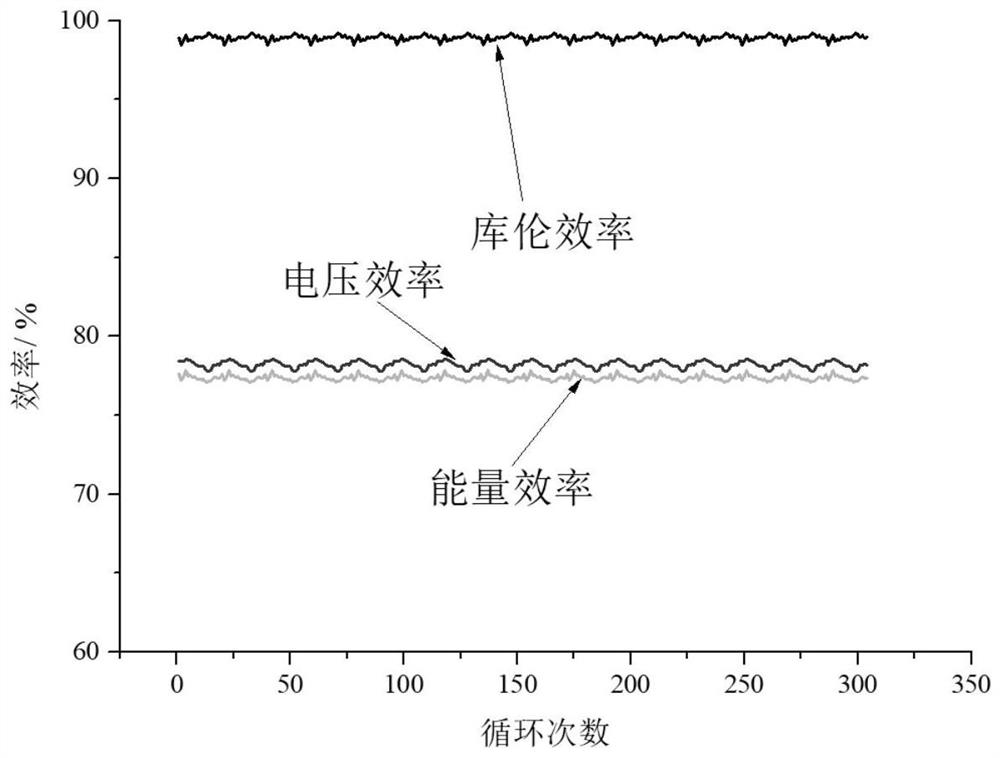

A composite ion and conductive membrane technology, applied in the Daramic composite ion conductive membrane and its preparation and application fields, can solve the problems of low coulombic efficiency and capacity retention, poor cycle stability, poor pore size uniformity, etc., and achieve good ion conductivity and stability. Good performance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

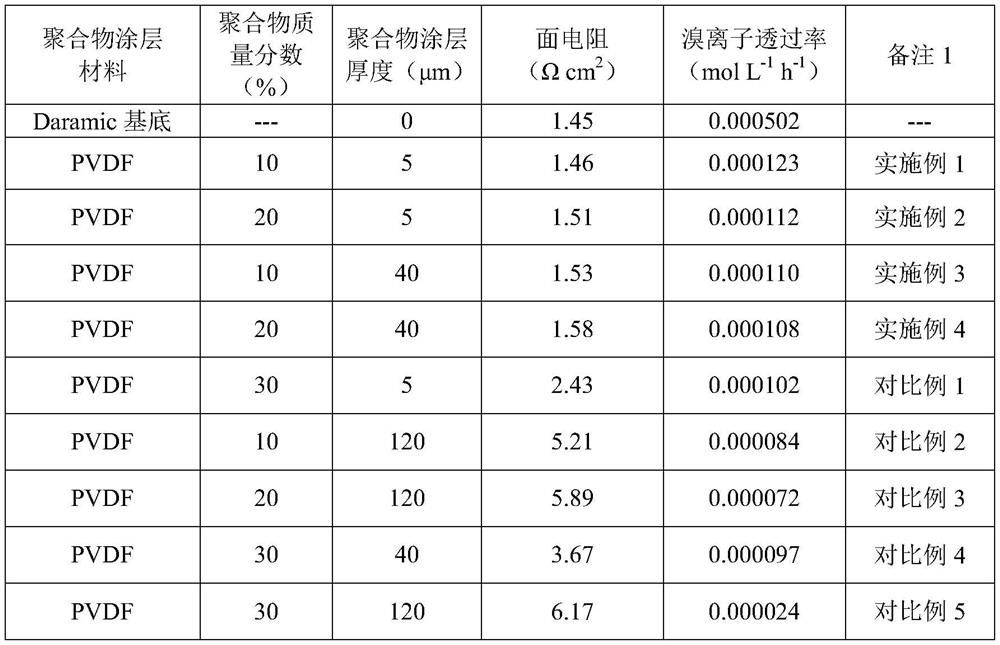

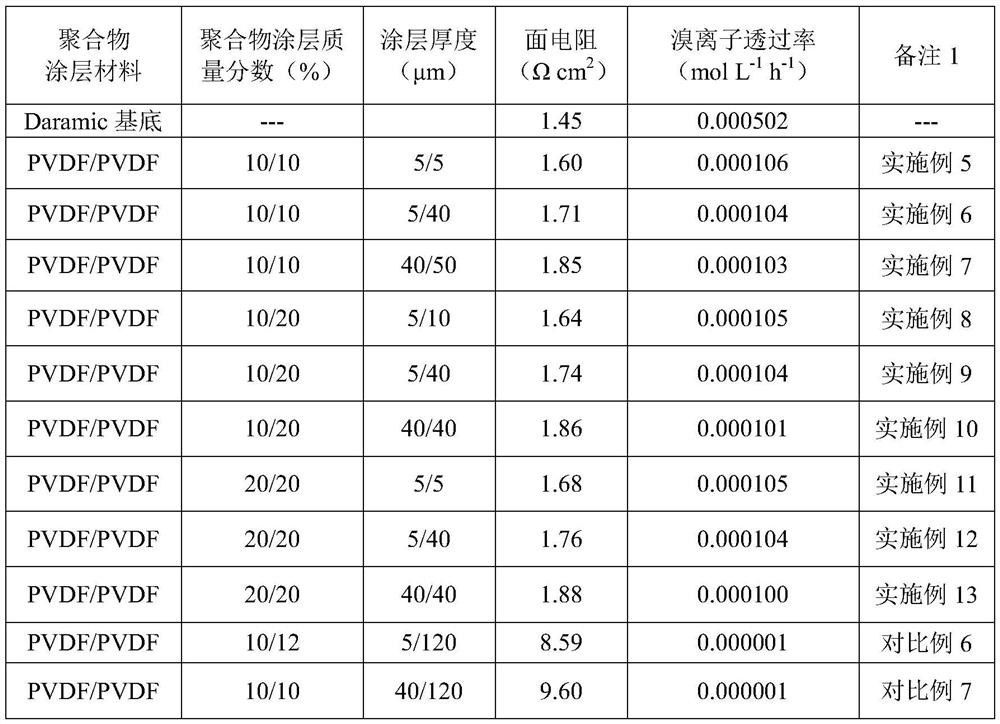

Embodiment 1

[0031] First dissolve polyvinylidene fluoride (PVDF) in the organic solvent DMAc, and stir fully at 25°C for 48 hours to form a uniform blend solution; the mass concentration of PVDF is 10%; then the prepared PVDF solution is evenly coated On the Daramic membrane substrate, immersed in non-solvent (water) at 50°C for 2h, the prepared Daramic membrane substrate (thickness: 200 μm, porosity: 60%, pore size distribution range: 0.1-100nm, the following examples and comparative examples The Daramic membranes used in this paper all adopt this parameter) One side is coated with a Daramic composite ion-conducting membrane with a porous PVDF coating, and the thickness of the porous PVDF coating is 5 μm.

[0032] The performance of the prepared Daramic composite ion-conducting membrane is tested and compared with the performance of the Daramic membrane substrate. The present invention takes a zinc-bromine flow battery as an example. The surface resistance of the prepared Daramic composi...

Embodiment 2

[0035] The polymer solution was prepared according to the method described in Example 1 above to prepare a Daramic composite ion-conducting membrane, except that the mass concentration of PVDF was 20% (Table 1).

[0036] The performance of the prepared Daramic composite ion-conducting membrane was tested, and compared with the performance of the Daramic composite ion-conducting membrane prepared in Example 1 and the performance of the Daramic membrane substrate. The present invention takes a zinc-bromine flow battery as an example. The surface resistance of the prepared Daramic composite ion-conducting membrane is as shown in table 1, and it is higher than the surface resistance of the prepared Daramic composite ion-conducting membrane and the Daramic membrane substrate of embodiment 1, shows that the raising of PVDF mass concentration makes the prepared Daramic The impedance of the composite ion-conducting membrane increased and the ion conductivity decreased (Table 6). This ...

Embodiment 3

[0039] The polymer solution was prepared according to the method described in Example 1 above to prepare a Daramic composite ion-conducting membrane, except that the thickness of the porous PVDF coating was 40 μm (Table 1).

[0040] The performance of the prepared Daramic composite ion-conducting membrane was tested, and compared with the performance of the Daramic composite ion-conducting membrane prepared in Example 1 and the performance of the Daramic membrane substrate. The present invention takes a zinc-bromine flow battery as an example. The surface resistance of the prepared Daramic composite ion-conducting membrane is as shown in Table 1, which is higher than the surface resistance of the prepared Daramic composite ion-conducting membrane and the Daramic membrane substrate in Example 1, showing that the improvement of the thickness of the porous PVDF coating makes the prepared The impedance of the Daramic composite ion-conducting membrane increases because the greater t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com